Kuwana Metals

Kuwana Metals Aera FC-R7700 Series Mass Flow Controller

Manufacturer: Kuwana Metals, Ltd.

Model : Aera FC-R7700 Series

Features

- Elastomer seals

- VCR^TM and Swagelok^TM compatible connections

- Full-scale flow ranges from 10 SCCM to 50 SLM

- Normally-closed or normally-open solenoid control valve

- Leak integrity of 1×10-6 atm-cc/s of He

Benefits

- Fast response— ≤ 2 s flow-settling time

- Easy integration—standard connectors and dimensions

Specifications

| Operational | FC-R7700CD/FC-R7700D Series | FC-R7710CD/FC-R7710D Series |

|---|---|---|

| Full-Scale Range | 10 SCCM to 5 SLM | N/O: 5 to 20 SLM* N/C: 5 to 50 SLM** |

| Response Time | ≤ 2 s to within ±2% of full scale 0→100%, SEMI E17-91 | |

| Flow Accuracy with calibration gas @22°C ±3°C | ≤ ±1% of full scale | ≤ ±2% of full scale |

| Linearity | ≤ ±0.5% of full scale | ≤ ±0.5% of full scale¹ |

| Repeatability | ≤ ±0.2% of full scale | |

| Leak Integrity | 1×10^-6 atm-cc/s (He) max;1×10^-7 Pa·m³/s (He) max | |

| Flow Control Range | 2 to 100% of full scale | |

| Normal Operating Pressure | 49 to 275kPaD | 69 to 275kPaD² 69 to 275kPaD³ |

| Maximum Operating Pressure | 490kPaG | |

| Proof Pressure | 1MPaG | |

| Operating Temperature Range | 5 to 45°C (41 to 113°F)Gas temperature needs to be the same as the atmospheric temperature. | |

- ※1: Less than ±1% for Full Scale Flow greater than 30SLM

- ※2: N/O: Normally Open Valve Model

- ※3: N/C: Normally Closed Valve Model [20 SLM < N2 density flow ≤ 50 SLM: 147 to 275 kPaD]

- These specifications are valid only in lab conditions used in factory testing, with standard configuration.

| Physical | FC-R7700CD/FC-R7700D Series | FC-R7710CD/FC-R7710D Series |

|---|---|---|

| Control Valve Type | Normally-open or normally-closed solenoid | |

| External seals | Fluoroelastomer or Chloroprene Rubber | |

| Materials | Stainless-steel type 316L, 316, PTFE, Magnetic Stainless, Fluoro Rubber, Chloroprene Rubber* | |

| Standard Fittings | 1/4″ VCRTM, 1/4″ Swagelok ^ TM compatible | |

| Orientation | May be mounted in any position | |

| Mass | 1.0 kg (2.2 lb) | |

- Fluoro Rubber or Chloroprene Rubber is used when N2 density flow is 11.096 SLM or greater with normally open valve models.

- Material used also depends on the applied gas. Contact factory for information on what material is used.

- Fluoro Rubber or Chloroprene Rubber is used when N2 density flow is 551 SCCM or greater with normally closed valve models.

- Materials used also depends on the gas.

| Electrical | FC-R7700CD/FC-R7700D Series | FC-R7710CD/FC-R7710D Series |

|---|---|---|

| Input Power | +15 VDC ±2%, 25 mA -15 VDC ±2%, 180 mA | |

| Power Consumption | 3.1 W max | |

| Input Command Signal | 0 to 5 VDC Input impedance > 1MΩ | |

| Output signal | 0 to 5 VDC Load impedance > 2kΩ | |

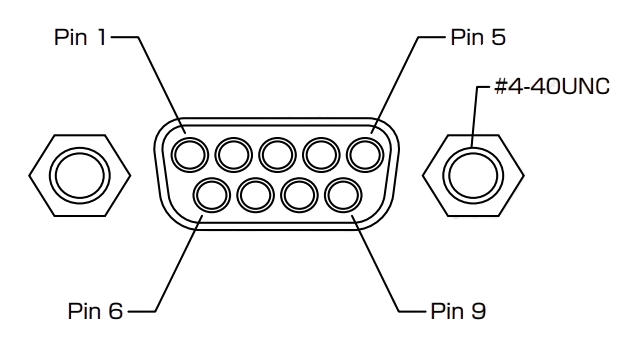

Electrical Connections

| 9-Pin D-sub, pin contact connector | |

|---|---|

| 1 | VALVE OPEN/CLOSE* |

| 2 | OUTPUT(DC 0〜5V/0-100%) |

| 3 | POWER DC +15V |

| 4 | COMMON |

| 5 | POWER DC -15V |

| 6 | CONTROL (DC 0〜5V/0-100%) |

| 7 | COMMON |

| 8 | COMMON |

| 9 | VALVE TEST PT.(DC 0〜-13V) |

- Connection to +15V OPEN, Connection to -15V : CLOSE (Normally closed valve model)

- Connection to +15V CLOSE, Connection to -15V : OPEN (Normally open valve model)

Model and Suffix Codes

| Category | Description | Suffix Codes | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Product Type | Mass flow controller | FC- | … | … | … | … | … | … | … |

| RoHS Compliance | Compliant with RoHS directives | … | R | … | … | … | … | … | … |

| Full-Scale Range | 10 SCCM to 5 SLM | … | … | 7700 | … | … | … | … | … |

| 5 to 50 SLM | … | … | 7710 | … | … | … | … | … | |

| Control Valve | Normally-closed | … | … | … | C | … | … | … | … |

| Normally-open | … | … | … | (Blank) | … | … | … | … | |

| Connector | Aera 9-Pin D | … | … | … | … | D | … | … | … |

| Fittings | 1/4” VCR^TM compatible | … | … | … | … | … | 4V | … | … |

| 1/4” Swagelok^TM compatible | … | … | … | … | … | 4S | … | … | |

| Gas | Type of gas | … | … | … | … | … | … | N2 | … |

| Flow | Flow range of gas (SCCM or SLM) | … | … | … | … | … | … | … | 200 |

| Single-Gas Example | FC- | R | 7700 | C | D | 4V | N2 | 200 SCCM | |

| (MFC, RoHS compliant, 9-pin D connector, normally-closed valve, 1/4” VCR^TM fittings, N2 gas, 200 SCCM full-scale range) | |||||||||

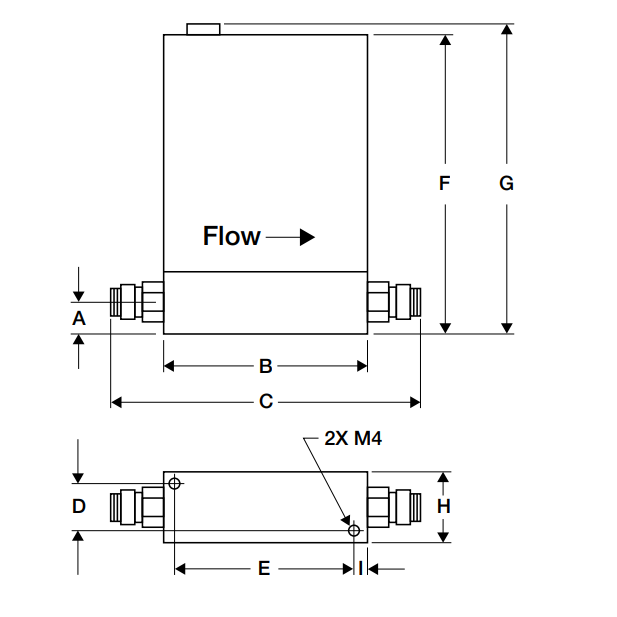

Dimensions

| FC-R7700CD/FC-R7700D Series | FC-R7710CD/FC-R7710D Series | |

|---|---|---|

| A | 12.7 mm (0.5″) | 12.7 mm (0.5″) |

| B | 76.0 mm (3.0″) | 78.5 mm (3.09″) |

| C | 124.0 mm (4.9″) | 124.0 mm (4.9″) |

| D | 18.3 mm (0.72″) | 18.3 mm (0.72″) |

| E | 69.0 mm (2.7″) | 69.0 mm (2.7″) |

| F | 119.0 mm (4.7″) | 119.0 mm (4.7″) |

| G | 125.0 mm (4.92″) | 125.0 mm (4.92″) |

| H | 32.0 mm (1.3″) | 32.0 mm (1.3″) |

| I | 3.5 mm (0.2″) | 3.5 mm (0.14″) |

Related Products

-

Kuwana Metals A Series Chilled Tower

-

Kuwana Metals Malleable Iron Pipe Fittings For General Use

-

Kuwana Metals SAM 1480G / 2480G Series Mass Flow Controller

-

Kuwana Metals Aera HG200 Series HC100/HM100 Series Pressure Insensitive (PI) Mass Flow Controller/Digital Mass Flow Controller (Non-PI) Mass Flow Meter

-

Kuwana Metals Aera Transformer Digital Mass Flow Products

-

Kuwana Metals Aera FC-R7800 Series Mass Flow Controller