Kuwana Metals

Kuwana Metals Aera Transformer Digital Mass Flow Products

Manufacturer: Kuwana Metals, Ltd.

Model : Aera Transformer

Features

- Multi-gas, multi-range selection

- Fast response

- All-metal seals

- Field programmable*

- Device Net^TM, RS-485, or analog control

- Multiple alarm and diagnostic capabilities

- RoHS compliant

Benefits

- Outstanding accuracy, repeatability, and stability

- Superior reliability

- Comprehensive communication and control

- Easy integration

- Substantial cost savings

- World-class service and support

Specifications

| Operational | 780X/785X Series | 781X/786X Series | 782X Series |

|---|---|---|---|

| Full-Scale Range (N2 Equivalent) | Single-gas models—10 sccm to 5 slm | Single-gas models—5 to 50 slm | Single-gas models—5 to 50 slm |

| Multi-gas model (1)—10 to 30 sccm | Multi-gas model (7)—5001 to 10, 000 sccm | ─ | |

| Multi-gas model (2)—31 to 100 sccm | Multi-gas model (8)—10,001 to 30,000 sccm | ─ | |

| Multi-gas model (3)—101 to 300 sccm | ─ | ─ | |

| Multi-gas model (4)—301 to 1000 sccm | ─ | ─ | |

| Multi-gas model (5)—1001 to 3000 sccm | ─ | ─ | |

| Multi-gas model (6)—3001 to 5000 sccm | ─ | ─ | |

| Accuracy | ≤ ±1% of set point (25 to 100% of full scale) ≤ ±0.25% of full scale (2 to 25% of full scale) | ≤ ±2.0% of full scale | |

| Settling Time | ≤ 1.0 s typical per SEMI E17-91 (above 10% of full scale) | ≤ 4.0 s | |

| Linearity | ≤ ±0.5% of full scale | ≤ ±1.0% of full scale | |

| Repeatability | ≤ ±0.2% of full scale | ||

| Leak Integrity | 1×10^-11 Pam3/s (He) max | ||

| Control Range | 2 to 100% of full scale | ||

| Differential Pressure | 7 to 40 psiD (49 to 275 kPaD) | 21 to 40 psiD (147 to 275 kPaD) | |

| Max Operating Pressure | 70 psiG (490 kPaG) | ||

| Proof Pressure | 140 psiG (981 kPaG) | ||

| Temperature | 15 to 50°C | ||

| Alarm/Diagnostics | Flow, valve voltage, auto-zero adjustment, communications, and microprocessor errors | ||

| Physical | 780X/785X Series | 781X/786X Series | 782X Series |

|---|---|---|---|

| Control Valve Type | Normally-closed or normally-open solenoid | ||

| Seals | Metal | ||

| Materials | 316LSS, 316SS, PTFE, KM45 | ||

| Standard Fittings | 1/4″ VCR^TM compatible; 1.5”/1.125” IGS bottom/surface mount (c-seal or Wseal^TM) | 3/8” VCR^TM compatible; IGS bottom/ surface mount (c-seal or Wseal^TM) | |

| Surface Finish | Electropolished and ultra-cleaned to ≤ 5 Ra | ||

| Attitude Sensitivity | May be mounted in any position | ||

| Weight | 1.0 kg (1/4” VCR^TM compatible) | 2.8 kg (3/8” VCR^TM compatible) | |

| Electrical | 780X/785X Series | 781X/786X Series | 782X Series |

|---|---|---|---|

| Connection Type | 9-pin D or DeviceNet^TM | ||

| Input Power | +15 VDC ±2% at ≤ 140 mA, -15 VDC ±2% at ≤ 240 mA | ||

| DeviceNet^TM: +11 VDC at 550 mA, +24 VDC at 225 mA | |||

| Power Consumption | 4.5 W max | 4.8 W max | |

| Input Signal | Analog mode: 0 to 5 VDC (input impedance > 1 MΩ) | ||

| Digital mode: 0 to 100% | |||

| DeviceNet^TM: ODVA (125 K, 250 K, 500 Kbps) | |||

| Output Indication | Analog mode: 0 to 5 VDC (input impedance > 2 kΩ) | ||

| Digital mode: 0 to 100% | |||

| DeviceNet^TM: ODVA (125 K, 250 K, 500 Kbps) | |||

| Digital/Service Communications | EIA standard, RS-485, two-wire, half-duplex, multi-drop with one RJ-11 connector (DeviceNet® models) or two RJ-11 connectors (9-pin D models) | ||

- Note: For full model and suffix code information, see Model and Suffix Codes on next page. Specifications are subject to change without notice.

Model and Suffix Codes

■ Mass Flow Controllers

| Category | Description | Suffix Codes | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Product Type | Mass flow controller | FC- | … | … | … | … | … | … | … | … |

| Connector Type | DeviceNet™ | … | DN | … | … | … | … | … | … | … |

| 9-pin D | … | PA | … | … | … | … | … | … | … | |

| RoHS Compliance | Compliant with RoHS directives | … | … | R | … | … | … | … | … | … |

| Full-Scale Flow Range※1 | 10 sccm to 5 slm | … | … | … | 780 | … | … | … | … | … |

| … | … | … | 7800 | … | … | … | … | … | ||

| … | … | … | 785 | … | … | … | … | … | ||

| … | … | … | 7850 | … | … | … | … | … | ||

| 5 to 50 slm | … | … | … | 781 | … | … | … | … | … | |

| … | … | … | 7810 | … | … | … | … | … | ||

| … | … | … | 786 | … | … | … | … | … | ||

| … | … | … | 7860 | … | … | … | … | … | ||

| 50 to 200 slm | … | … | … | 782 | … | … | … | … | … | |

| … | … | … | 7820 | … | … | … | … | … | ||

| Control Valve | Normally-closed | … | … | … | … | C | … | … | … | … |

| Normally-open | … | … | … | … | … | … | … | … | … | |

| Connector※2 | Top mounted connector | … | … | … | … | … | T | … | … | … |

| Side mounted pigtail connector | … | … | … | … | … | Y | … | … | … | |

| Fittings | 1/4” VCR™ compatible | … | … | … | … | … | … | 4V | … | … |

| 3/8″ VCR™ compatible (782x Series only) | … | … | … | … | … | … | 6V | … | … | |

| 1.125” c-seal | … | … | … | … | … | … | BA | … | … | |

| 1.125” Wseal™ | … | … | … | … | … | … | BW | … | … | |

| 1.5” c-seal | … | … | … | … | … | … | BM | … | … | |

| 1.5” Wseal™ | … | … | … | … | … | … | BF | … | … | |

| Gas | Type of gas | … | … | … | … | … | … | … | N2 | … |

| Flow | Flow range of gas (sccm or slm) | … | … | … | … | … | … | … | … | … |

| Single-Gas Example | FC- | PA | R | 7800 | C | 4V | N2 | 200 | ||

| (MFC with 9-pin D connector, RoHS compliant, normally-closed valve, 1/4” VCR^TM compatible fittings, N2 gas, 200 sccm full-scale range) | ||||||||||

| Multi-Gas/Multi-Range | Configuration for MGMR functioning (see Full-Scale Ranges above for details for multi-gas models 1 through 8) | … | … | … | … | … | … | … | … | Multi -1 to -8 (10 sccm to 30 slm) |

| N2 equivalent | ||||||||||

| Multi-Gas Example | FC- | PA | R | 7800 | C | 4V | MULTI – 3 | |||

| (MFC with 9-pin D connector, RoHS compliant, normally-closed valve, 1/4” VCR^TM compatible fittings, 101 to 300 sccm full-scale range) | ||||||||||

- ※1 Three-digit flow range suffix codes are for DN Series models; Three-digit and four-digit flow range suffix codes are for available for PA Series models. Consult factory for details.

- ※2 Electronic options “T” and “Y” are available only for compact 785 and 786 Series.

■ Mass Flow Meters

| Category | Description | Suffix Codes | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Product Type | Mass flow meter | FM- | … | … | … | … | … | … | … |

| Connector Type | DeviceNet™ | … | DN | … | … | … | … | … | … |

| 9-pin D | … | PA | … | … | … | … | … | … | |

| RoHS Compliance | Compliant with RoHS directives | … | … | R | … | … | … | … | … |

| Full-Scale Flow Range※1 | 10 sccm to 5 slm | … | … | … | 860 | … | … | … | … |

| … | … | … | 8600 | … | … | … | … | ||

| … | … | … | 865 | … | … | … | … | ||

| … | … | … | 8650 | … | … | … | … | ||

| 5 to 50 slm | … | … | … | 861 | … | … | … | … | |

| … | … | … | 8610 | … | … | … | … | ||

| … | … | … | 866 | … | … | … | … | ||

| … | … | … | 8660 | … | … | … | … | ||

| 50 to 400 slm | … | … | … | 862 | … | … | … | … | |

| … | … | … | 8620 | … | … | … | … | ||

| Connector※2 | Top mounted connector | … | … | … | … | T | … | … | … |

| Side mounted pigtail connector | … | … | … | … | Y | … | … | … | |

| Fittings | 1/4” VCR™ compatible | … | … | … | … | … | 4V | … | … |

| 3/8″ VCR™ compatible (862x Series only) | … | … | … | … | … | 6V | … | … | |

| 1.125” c-seal | … | … | … | … | … | BA | … | … | |

| 1.125” Wseal™ | … | … | … | … | … | BW | … | … | |

| 1.5” c-seal | … | … | … | … | … | BM | … | … | |

| 1.5” Wseal™ | … | … | … | … | … | BF | … | … | |

| Gas | Type of gas | … | … | … | … | … | … | N2 | … |

| Flow | Flow range of gas (sccm or slm) | … | … | … | … | … | … | … | … |

| Example | FM- | PA | R | 8600 | T | 4V | N2 | 200 | |

| (MFM with 9-pin D connector, RoHS compliant, top-mounted connector, 1/4” VCR^TM compatible fittings, N2 gas, 200 sccm full-scale range) | |||||||||

- ※1 Three-digit flow range suffix codes are for DN Series models; Three-digit and four-digit flow range suffix codes are for available for PA Series models. Consult factory for details.

- ※2 Electronic options “T” and “Y” are available only for compact 865 and 866 Series.

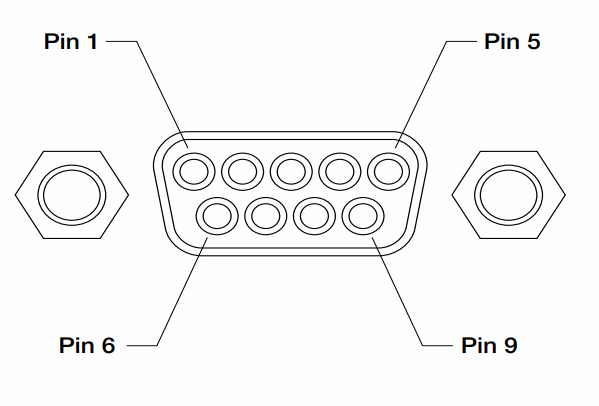

Electrical Connections

| 9-Pin D | |

|---|---|

| 1 | VALVE OPEN/CLOSE* |

| 2 | OUTPUT (0 TO 5 VDC) |

| 3 | POWER +15 VDC |

| 4 | POWER COMMON (VALVE RETURN) |

| 5 | -15 VDC |

| 6 | CONTROL (0 TO 5 VDC) |

| 7 | SIGNAL COMMON |

| 8 | SIGNAL COMMON |

| 9 | 9 VALVE TEST POINT (0 TO +4 VDC) |

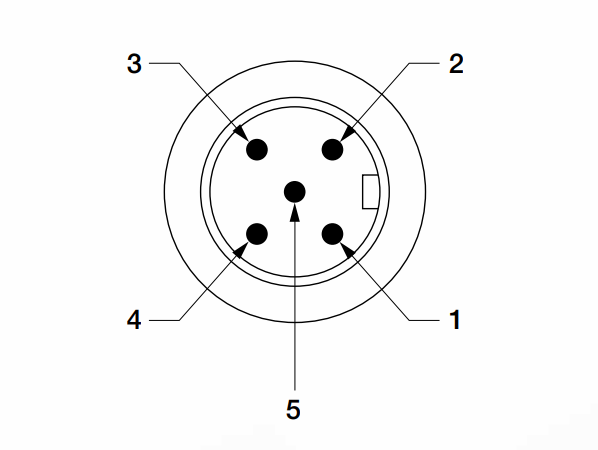

| DeviceNet^TM | |

|---|---|

| 1 | DRAIN |

| 2 | V+ |

| 3 | V |

| 4 | CAN_H |

| 5 | CAN_L |

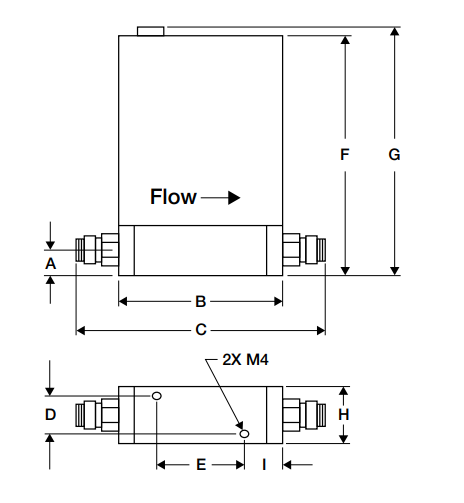

Dimensions

■ Models with VCR^TM Compatible Fittings

| 780x, 781x, 860x, 861x Series | 785x, 786x, 865x, 866x Series | 782x Series | |

|---|---|---|---|

| A | 12.7 mm (0.5”) | 12.7 mm (0.5”) | 15.0 mm (0.6”) |

| B | 83.0 mm (3.3”) | 65.0 mm (2.6”) | 115 mm (4.5”) |

| C | 124.0 mm (4.9”) | 106.0 mm (4.2”) | 192.3 mm (7.8”) |

| D | 18.0 mm (0.7”) | 16.3 mm (0.6”) | 25.5 mm (1.0”) |

| E | 69.0 mm (2.7”) | 29.0 mm (1.1”) | 90.0 mm (3.5”) |

| F | 127.0 mm (5.0”) | 127.0 mm (5.0”) | 150.0 mm (5.9”) |

| G | 132.0 mm (5.2”) | 132.0 mm (5.2”) | 154.0 mm (6.1”) |

| H | 28.6 mm (1.1”) | 30.2 mm (1.2”) | 38.0 mm (1.5”) |

| I | 7.0 mm (0.3”) | 16.0 mm (0.6”) | 24.4 mm (0.96”) |

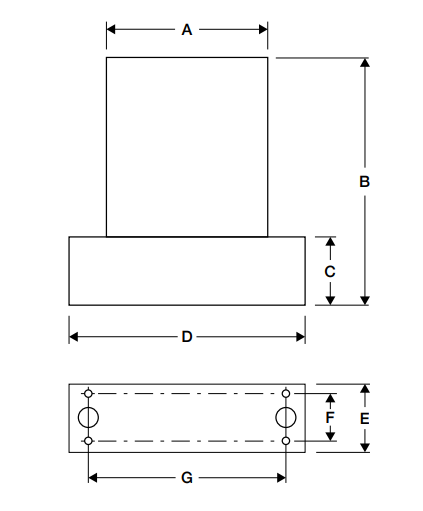

■ Models with IGS^TM Compatible Fittings

| 780x, 781x, 860x, 861x Series | 785x, 786x, 865x, 866x Series | |||

|---|---|---|---|---|

| 1.125” IGS^TM Fittings | 1.5” IGS^TM Fittings</strong | 1.125” IGS^TM Fittings | s 1.5” IGS^TM Fittings</strong | |

| A | 70.4 mm (2.8”) | 70.4 mm (2.8”) | 70.4 mm (2.8”) | 70.4 mm (2.8”) |

| B | 127.0 mm (5.0”) | 127.0 mm (5.0”) | 127.0 mm (5.0”) | 127.0 mm (5.0”) |

| C | 25.4 mm (1.0”) | 25.4 mm (1.0”) | 25.4 mm (1.0”) | 25.4 mm (1.0”) |

| D | 105.0 mm (4.1”) | 105.0 mm (4.1”) | 92.8 mm (3.6”) | 92.8 mm (3.6”) |

| E | 28.6 mm (1.1”) | 38.1 mm (1.5”) | 28.6 mm (1.1”) | 28.6 mm (1.1”) |

| F | 21.8 mm (0.9”) | 30.0 mm (1.2”) | 21.8 mm (0.9”) | 30.0 mm (1.2”) |

| G | 92.0 mm (3.6”) | 92.0 mm (3.6”) | 79.8 mm (3.2”) | 79.8 mm (3.2”) |

Related Products

-

Kuwana Metals SAM 1480G / 2480G Series Mass Flow Controller

-

Kuwana Metals Malleable Iron Pipe Fittings For General Use

-

Kuwana Metals SAM PS200 Series Pressure-Based PI Mass Flow Controller

-

Kuwana Metals Aera FC-R7800 Series Mass Flow Controller

-

Kuwana Metals SAM SFC1480FX / SFC2480FX Series Mass Flow Controller

-

Kuwana Metals S-A075M Chilled Tower