Kuwana Metals

Kuwana Metals S-A075M Chilled Tower

Manufacturer: Kuwana Metals, Ltd.

Model : S-A075M

Specification

| Model | CTS-A075M | |||

|---|---|---|---|---|

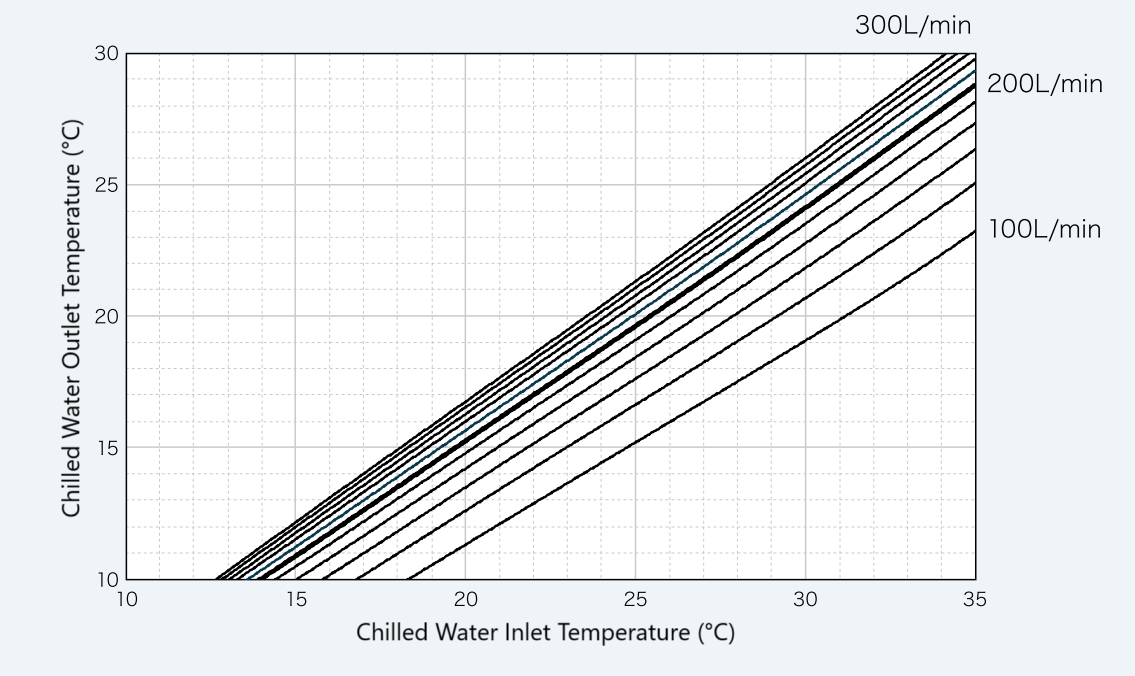

| Performance※1 | Inlet Temperature 25°C | Cooling capacity | kW | 75.6 |

| Outlet Temperature 20°C | Chilled water flow rate | L/min | 216.7 | |

| Inlet Temperature 35°C | Cooling capacity | kW | 83.3 | |

| Outlet Temperature 25°C | Chilled water flow rate | L/min | 119.3 | |

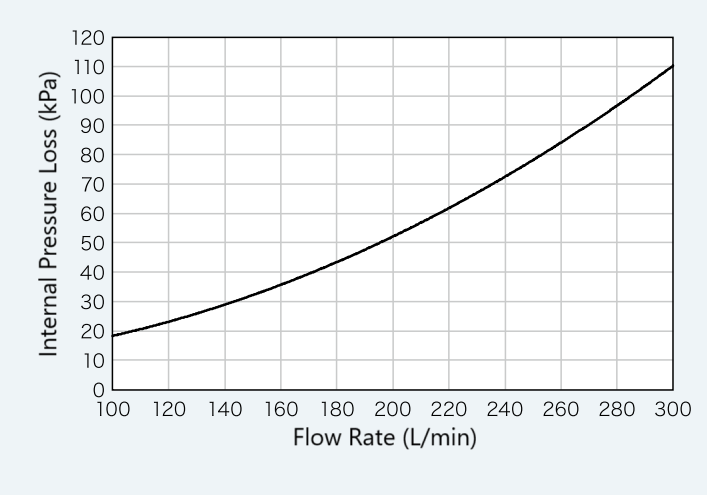

| Water Flow Range (From min to max) | L/min | 100~300 | ||

| Internal Pressure Loss(Based on flow) | kPa at (L/min) | 53(200) | ||

| Rated refrigeration capacity | Ton | 8.57 | ||

| High-Pressure Gas Safety Act applicable classification ※2 | Notification Not Required | |||

| Type of refrigerant | R32 | |||

| Refrigerant charge amount ※3 | kg | 9 | ||

| Exterior | Control panel, compressor box, Panel: High corrosion-resistant plated steel sheet Main frame: Hot-dip galvanized | |||

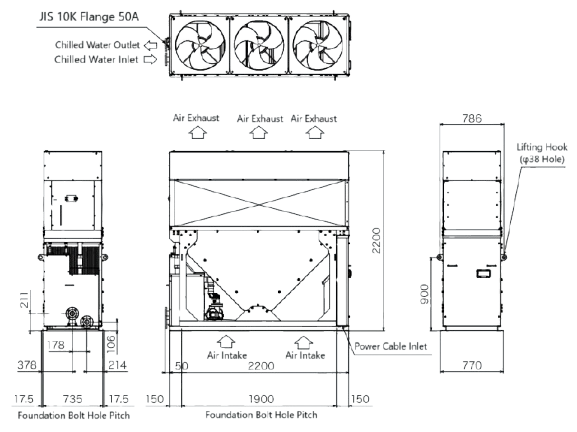

| External Dimensions | Width | mm | 770 | |

| Depth | mm | 2200 | ||

| Height | mm | 2200 | ||

| Blower | Model | Axial Fan | ||

| Outer Diameter | mm | 600 | ||

| Motor Output | kW × units | 2.2 × 3 | ||

| Circulation Pump | Model | Magnet Pump | ||

| Motor Output | kW × units | 0.4 × 1 | ||

| Compressor | Model | Scroll Type Fully Sealed Electric Compressor | ||

| Motor Output | kW × units | 5.5 × 1 | ||

| Refrigerant Control System | Electronic Expansion Valve | |||

| Control Device | PLC, Inverter | |||

| Protection Device | High-Pressure Cutoff Device, Low-Pressure Cutoff Device Anti-Freeze Temperature Switch, Discharge Gas Overheat Prevention Temperature Switch Breaker (NFB), Thermal Relay (Overload Protection Device) | |||

| Electrical Characteristics ※4 | Power Consumption | kW | 20.9 | |

| Operating Current | A | 64 | ||

| Power Supply ※5 | AC3φ 200V 50/60Hz | |||

| Product Weight (Operating Weight) | kg | 880 (900) | ||

| Noise Level (Measured at 2m distance and 1.5m height) ※6 | dB(A) | 66 | ||

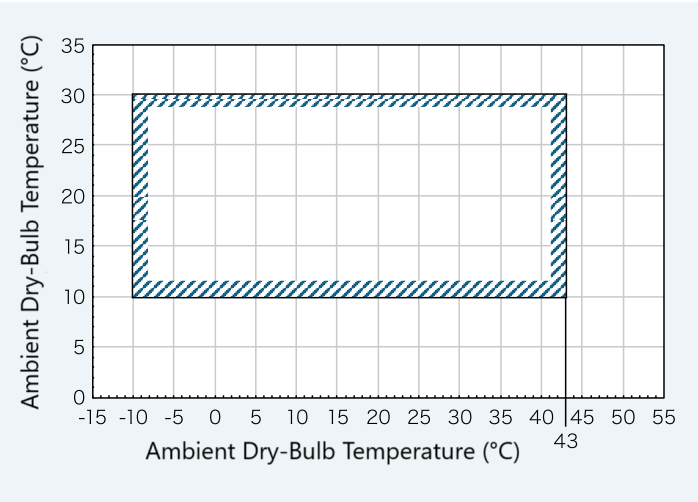

| Ambient Temperature | °C | -10 ~ +43 | ||

| Cooling Water | Used Fluid | Clean water (Must meet JRA water quality standards) | ||

| Chilled Water Inlet/Outlet | JIS 10K Flange 50A | |||

| Maximum Operating Pressure | MPa | 0.7 | ||

| Internal Circulating Water | Fluid | Propylene Glycol 30wt% | ||

| Freezing Temperature | °C | -10 | ||

| Retained Water Volume | L | 60 | ||

- ※1 Performance (Cooling capacity, Chilled water flow rate). The values are based on a dry-bulb ambient temperature of 35°C.

- ※2 High-Pressure Gas Safety Act Applicable Classification. No high-pressure gas manufacturing notification is required under the regulations of the High-Pressure Gas Safety Act.

- ※3 Refrigerant Charge Amount. The specified amount is based on standard specifications. Additional charging may be necessary under certain design conditions to ensure performance. (The final charge amount is indicated on the nameplate.)

- ※4 Electrical Characteristics (Power Consumption, Operating Current). The values are based on conditions of 35°C dry-bulb temperature, 35°C chilled water inlet temperature, and 25°C chilled water outlet temperature. Transformer capacity and wiring capacity should be at least 1.2 times the indicated power consumption and operating current.

- ※5 Internal Control Circuit. Operates on DC24V (Some models support DC12V, DC5V).

- ※6 Noise Value (Measured at a Distance of 2m and Height of 1.5m). The stated value represents the measurement in an environment without reflective surfaces (A-weighted sound scale).. In actual installation conditions, the surrounding environment may cause variations of approximately ±3 dB(A). During summer, to protect the equipment, the upper rotation speed of the blower fan may temporarily increase, which can result in higher noise levels.

Outline Drawing

Foundation Reference Drawing

Performance Curve Diagram

Internal Pressure Loss

Water Supply Temperature and Operating Range

Electrical Wiring

AC 3-Phase 200V (50/60Hz)

| Power Consumption (kW) | Operating Current (A) | Minimum Wire Size (mm²) | Recommended ELB (A) | ||

|---|---|---|---|---|---|

| Power Line | External Output Circuit | Ground Wire | |||

| 20.9 | 64 | 60 | 2.0 | 14 | 150 |

- 1.The values for power consumption and operating current are based on the conditions of 35°C ambient dry-bulb temperature, 35°C chilled water inlet temperature, and 25°C chilled water outlet temperature. Power consumption and operating current may vary depending on operating conditions.

- 2. If the voltage drop exceeds 2% over the maximum wiring length, the internal wiring regulations require increasing the wire thickness.

- 3.The minimum wire thickness applies to metal conduits (wire), synthetic resin conduits, floor ducts, and cable wiring. For metal conduits and synthetic resin conduits, the specification is based on three wires housed within the same conduit.

Options

Optional accessories are available for installation at the time of order. Please contact our sales department for more details.

- Support for Different Voltages

- Modular Controller

- Corrosion-Resistant Specification (Salt Protection)

- Public Building Construction Specification

- External Pump Unit Specification

- Vibration Isolation Stand

- Snow Protection Hood

- Interlinked Snow Protection Hood

- Protective Mesh (Net)

- Strainer

⚠ Safety Precautions

- Regarding the Use of the Chiller Tower The chiller towers listed in this catalog are for general industrial use.

- Before Use Please read the instruction manual carefully before use and operate the unit correctly.

- Regarding Installation Installation should be performed by a qualified professional. Improper installation may result in water leakage, electric shock, or fire hazards.

- Regarding Installation Location Do not install the unit in locations where flammable gases may leak or where ignitable materials are present. Avoid areas where flammable gases may be generated, accumulate, or stagnate, and areas where carbon fibers or metal dust are floating, as they pose risks of fire or explosion.

Related Products

-

Kuwana Metals W Series Chilled Tower

-

Kuwana Metals FCMB35-10/FCD-S/SCS Series/WCB/A105/F304/PE80 Valves

-

Kuwana Metals SAM 1480G / 2480G Series Mass Flow Controller

-

Kuwana Metals Aera FC-R7700 Series Mass Flow Controller

-

Kuwana Metals SAM PS200 Series Pressure-Based PI Mass Flow Controller

-

Kuwana Metals Aera HG200 Series HC100/HM100 Series Pressure Insensitive (PI) Mass Flow Controller/Digital Mass Flow Controller (Non-PI) Mass Flow Meter