Kuwana Metals

Kuwana Metals SAM 1480G / 2480G Series Mass Flow Controller

Manufacturer: Kuwana Metals, Ltd.

Model : SAM 1480G / 2480G Series

Table of Models and Functions

| Model name | Function | Connection specifications | Communication specifications | ||

|---|---|---|---|---|---|

| Standard | Optional | Wseal™ Cseal UJR | RS232C RS485 DeviceNet™ | ||

| MG/MR function (Guaranteed accuracy with the actual gas) | PI function | LCD display unit | |||

| 1480FX 2480FX | * | MG / MR | |||

| 1480G1 2480G1 | * | * | * | MG / MR + PI | |

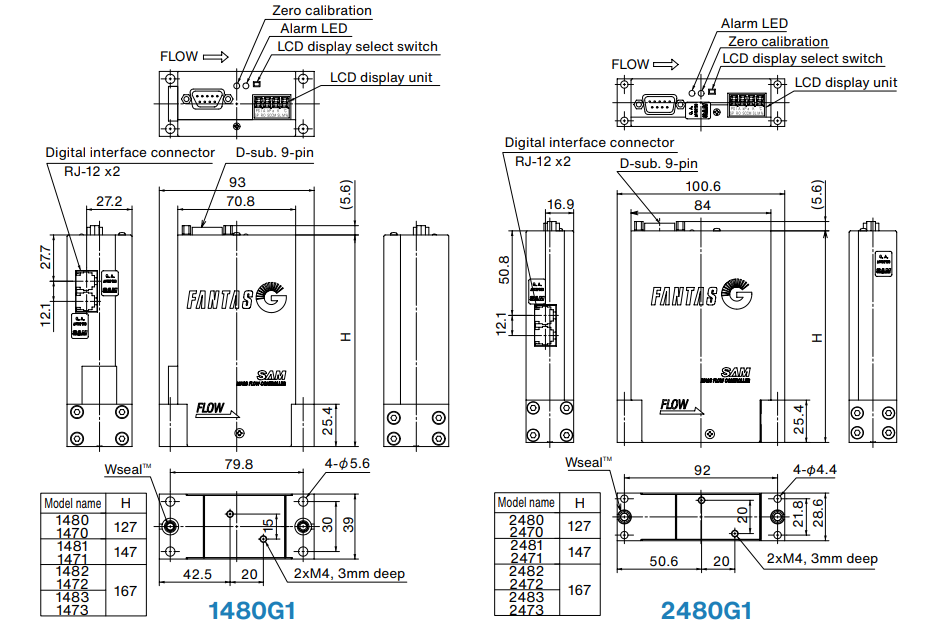

1480G1 / 2480G1 series

- For both the 1.5″ and 1.125″IGS™, PI Mass Flow Controllers

Dimensions

| Item | Specifications *1 | |||||

|---|---|---|---|---|---|---|

| Model name | SFC1480FX SFC2480FX | SFC1481FX SFC2481FX | SFC1482FX SFC2482FX | SFC1483FX SFC2483FX | ||

| Standard full scale flow rate (N2 equivalent) | 2SCCM ~5,500SCCM | ~11SLM | ~30SLM | ~50SLM | ||

| Function | Multi-gas/multi-range | |||||

| Valve operation | Normally closed / normally open | |||||

| Flow rate control range | 2~100% F.S. | |||||

| Operation pressure *2 | Inlet pressure | 0.05~0.3 MPa (G) 7.3~43.5 PSI (G) | 0.1~0.3 MPa (G) 14.5~43.5 PSI (G) | 0.2~0.3 MPa (G) 29.0~43.5 PSI (G) | ||

| Outlet pressure | Vacuum to ambient pressure | |||||

| Proof pressure | 1.0 MPa (G) 145 PSI (G) | |||||

| Temperature | Operation | 5~50 ºC | ||||

| Accuracy guaranteed | 15~35 ºC | |||||

| Heating temperature when not powered | 65ºC max | |||||

| Humidity | 35~80%RH (non condensing) | |||||

| Installation position | Horizontal, Vertical | Horizontal, Vertical (option) | ||||

| Flow rate setting signal | 0.1 to 5 VDC (absolute rating: Max. ±15 VDC) | |||||

| Flow rate output signal | 0 to 5 VDC (maximum output: ±15 VDC) | |||||

| Required power | +15 VDC ±4%, 140 mA max -15 VDC ±4%, 140 mA max | |||||

| Material of gas wetted surface | Housing, flange, valve seat | SUS316L | ||||

| Diaphragm | Ni-Co alloy | |||||

| Flow sensor | SUS316L | Ni | ||||

| Seal *4 | SUS316L | |||||

| Pressure sensor | SUS316L | |||||

| Surface finish of components that contact the gas | Specially electro-polished (standard) | |||||

| Fitting | Wseal™, Cseal, 1/4” UJR male | |||||

| LCD display unit | 4 digit display (6 x 4 mm), LED backlight | |||||

| External leakage standard | Max. 1×10^-11 Pa•m3/s (He) | |||||

| Accuracy | N2 gas | 10~100% | ± (0.5% S.P. + 0.15% F.S.) | |||

| 2~10% | ±0.2% F.S. | |||||

| Actual gas | 10~100% | ± (1.5% S.P. + 0.35% F.S.) | ||||

| 2~10% | ±0.5% F.S. | |||||

| Linearity | N2 gas | ±0.3% F.S | ||||

| Actual gas | ±1.0% F.S | |||||

| Repeatability | 10~100% | ± (0.1% S.P. + 0.05% F.S.) | ||||

| 2~10% | ±0.06% F.S. | |||||

| Flow rate sensor guaranteed zero point deviation range | ±0.5% F.S. / year, max. | |||||

| Temperature dependence | Zero point | ±0.01% F.S. / ºC (15~35 ºC) | ||||

| Span | ±0.01% S.P. / ºC (15~35 ºC) | |||||

| Response Time | 0% → (20~100%) | Max. 1.0 sec. to reach ±2% S.P of the set value | ||||

| 0% → (2~20%) | Max. 1.5 sec. to reach ±0.4% S.P of the set value. | |||||

| Flow rate fluctuation width during pressure variations | Pressure gradient: <0.5kPa 0.1PSI/0.12sec | ±1.0% S.P. | ||||

| Pressure gradient: >0.5kPa 0.1PSI/0.12sec | Pressure fluctuation width <0.02MPa 2.9PSI | ± (1.5% S.P. + 1.0%F.S.) | ||||

| Pressure fluctuation width 0.02~0.05MPa 2.9~7.3PSI | ± (3.0% S.P. + 1.0% F.S.) | |||||

| Flow rate change time when the pressure changes | Within 1 second of the pressure fluctuation | |||||

| Pressure senso | Pressure range | -99.9~999.9 kPa (G) -14.5~145 PSI (G) | ||||

| Accuracy | ±0.5% F.S. | |||||

| Repeatability | ±0.01% F.S. | |||||

| Temperature dependence | 0.05% / ºC | |||||

| Pressure output | LCD display and digital communication (no analog output) | |||||

| Temperature measuring range | 273.2~323.2 K (0~50 ºC) | |||||

- *1: The specifications above are guaranteed values when the MFC was measured by itself in standard conditions. The MFC may not meet the specifications above,

depending on the measurement conditions. - *2: The 147*G1 / 247*G1 series are also available for use with minute pressure differences. Please inquire separately for the specifications of our minute pressure

difference models. - *3: A model using a rubber seal is also available. Please inquire separately about the rubber seal specifications.

- *4: The PI function may not perform as specified in certain plumbing conditions.

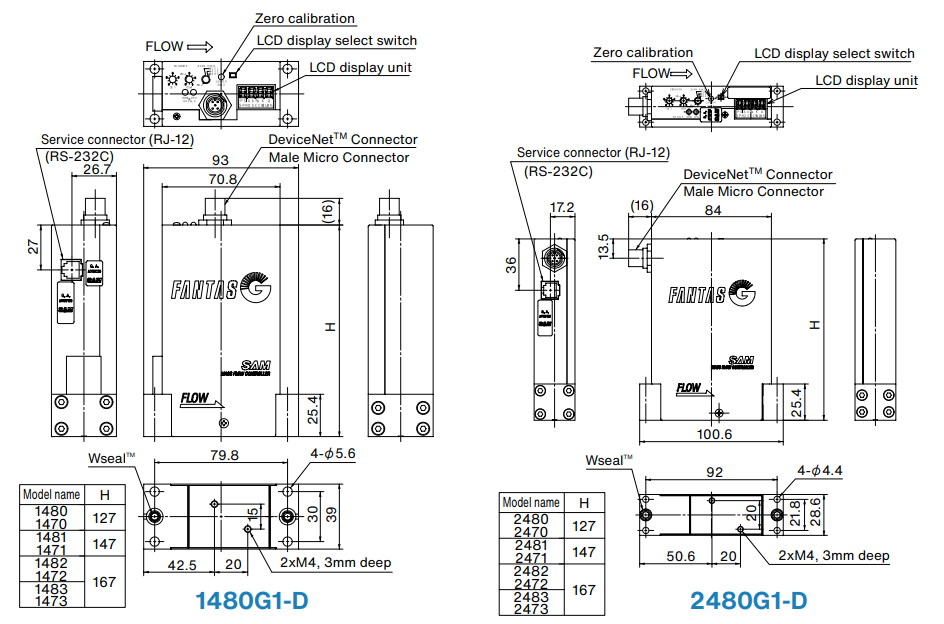

1480G1-D / 2480G1-D series

DeviceNet™ communication type For both the 1.5″ and 1.125″IGS™, PI Mass Flow Controllers

Dimensions

| Item | Specifications *1 | |||||

|---|---|---|---|---|---|---|

| Model name | 1480G1-D0 2480G1-D0 | 1481G1-D0 2481G1-D0 | 1482G1-D0 2482G1-D0 | 1483G1-D0 2483G1-D0 | ||

| Standard full scale flow rate (N2 equivalent) | 2SCCM ~5,500SCCM | 11SLM | 30SLM | 50SLM | ||

| Function | 1) Multi-gas/multi-range, 2) PI function, 3) LCD display (flow rate output, flow rate setting, pressure, and temperature) | |||||

| Valve operation | Normally closed / normally open | |||||

| Flow rate control range | 2~100% F.S. | |||||

| Operation pressure *2 | Inlet pressure | 0.05~0.3 MPa (G) 7.3~43.5 PSI (G) | 0.1~0.3 MPa (G) 14.5~43.5 PSI (G) | 0.2~0.3 MPa (G) 29.0~43.5 PSI (G) | ||

| Outlet pressure | Vacuum to ambient pressure | |||||

| Proof pressure | 1.0 MPa (G) 145 PSI (G) | |||||

| Temperature | Operation | 5~50 ºC | ||||

| Accuracy guaranteed | 15~35 ºC | |||||

| Heating temperature when not powered | 65ºC max | |||||

| Humidity | 35~80%RH (non condensing) | |||||

| Installation position | Horizontal, Vertical | Horizontal, Vertical (option) | ||||

| Flow rate setting signal | DeviceNet™ communication *3 | |||||

| Flow rate output signal | ||||||

| Required power | +24 VDC, 0.3 A max | |||||

| Material of gas wetted surface | Housing, flange, valve seat | SUS316L | ||||

| Diaphragm | Ni-Co alloy | |||||

| Flow sensor | SUS316L | Ni | ||||

| Seal *4 | SUS316L | |||||

| Pressure sensor | SUS316L | |||||

| Surface finish of components that contact the gas | Specially electro-polished (standard) | |||||

| Fitting | Wseal™, Cseal, 1/4” UJR male | |||||

| LCD display unit | 4 digit display (6 x 4 mm), LED backlight | |||||

| External leakage standard | Max. 1×10^-11 Pa•m3/s (He) | |||||

| Accuracy | N2 gas | 10~100% | ± (0.5% S.P. + 0.15% F.S.) | |||

| 2~10% | ±0.2% F.S. | |||||

| Actual gas | 10~100% | ± (1.5% S.P. + 0.35% F.S.) | ||||

| 2~10% | ±0.5% F.S. | |||||

| Linearity | N2 gas | ±0.3% F.S | ||||

| Actual gas | ±1.0% F.S | |||||

| Repeatability | 10~100% | ± (0.1% S.P. + 0.05% F.S.) | ||||

| 2~10% | ±0.06% F.S. | |||||

| Flow rate sensor guaranteed zero point deviation range | ±0.5% F.S. / year, max. | |||||

| Temperature dependence | Zero point | ±0.01% F.S. / ºC (15~35 ºC) | ||||

| Span | ±0.01% S.P. / ºC (15~35 ºC) | |||||

| Response Time | 0% → (20~100%) | Max. 1.0 sec. to reach ±2% S.P of the set value | ||||

| 0% → (2~20%) | Max. 1.5 sec. to reach ±0.4% S.P of the set value. | |||||

| Flow rate fluctuation width during pressure variations | Pressure gradient: <0.5kPa 0.1PSI/0.12sec | ±1.0% S.P. | ||||

| Pressure gradient: >0.5kPa 0.1PSI/0.12sec | Pressure fluctuation width <0.02MPa 2.9PSI | ± (1.5% S.P. + 1.0%F.S.) | ||||

| Pressure fluctuation width 0.02~0.05MPa 2.9~7.3PSI | ± (3.0% S.P. + 1.0% F.S.) | |||||

| Flow rate change time when the pressure changes | Within 1 second of the pressure fluctuation | |||||

| Pressure senso | Pressure range | -99.9~999.9 kPa (G) -14.5~145 PSI (G) | ||||

| Accuracy | ±0.5% F.S. | |||||

| Repeatability | ±0.01% F.S. | |||||

| Temperature dependence | 0.05% / ºC | |||||

| Pressure output | LCD display and digital communication (not analog output) | |||||

| Temperature measuring range | 273.2~323.2 K (0~50 ºC) | |||||

- *1: The specifications above are guaranteed values when the MFC was measured by itself in our standard conditions. The MFC may not meet the specifications above, depending on the

measurement conditions. - *2: The 147*G1-D / 247*G1-D series are also available for use with minute pressure differences. Please inquire separately for the specifications of our minute pressure difference

models. - *3: For details about DeviceNet™ communication, see page 10.

- *4: A model using a rubber seal is also available. Please inquire separately about the rubber seal specifications.

- *5: The PI function may not perform its specifications depending on each plumbing condition.

Related Products

-

Kuwana Metals Aera FC-R7800 Series Mass Flow Controller

-

Kuwana Metals Malleable Iron Pipe Fittings For General Use

-

Kuwana Metals SAM SFC1480FX / SFC2480FX Series Mass Flow Controller

-

Kuwana Metals FCMB35-10/FCD-S/SCS Series/WCB/A105/F304/PE80 Valves

-

Kuwana Metals S-A075M Chilled Tower

-

Kuwana Metals SAM PS200 Series Pressure-Based PI Mass Flow Controller