Kuwana Metals

Kuwana Metals W Series Chilled Tower

Manufacturer: Kuwana Metals, Ltd.

Model : W Series

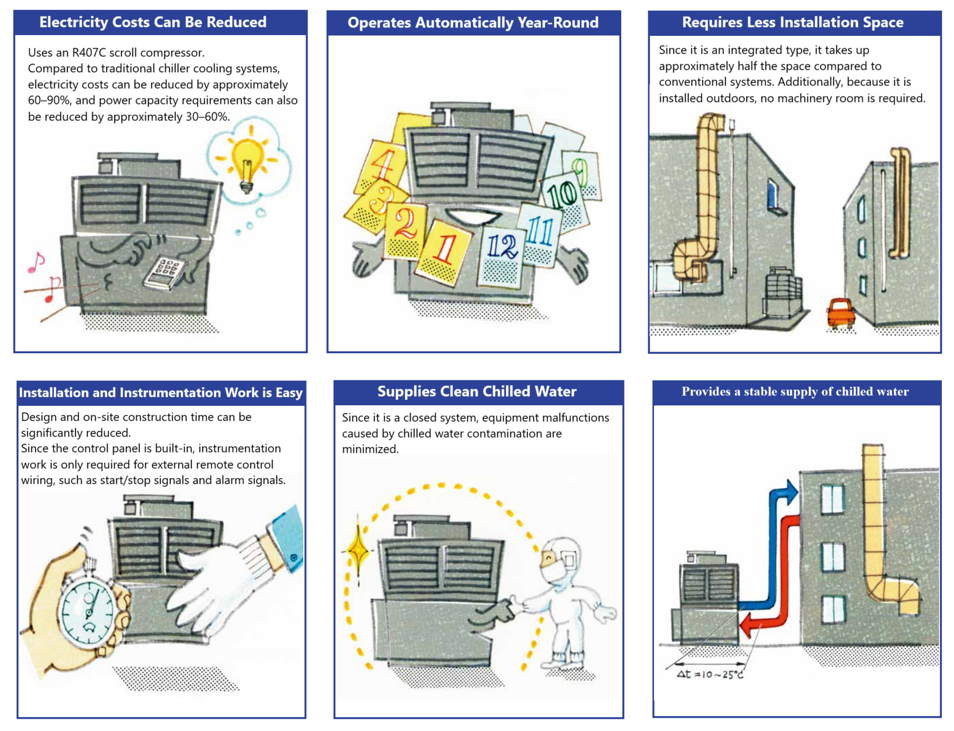

Features

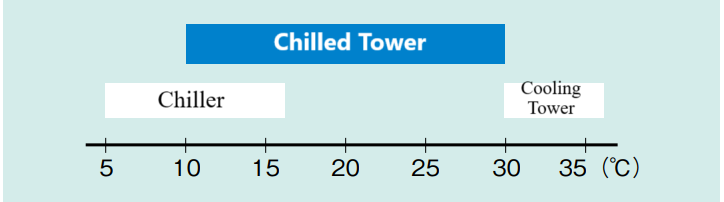

Supply Temperature Range

The supply temperature refers to the chilled water outlet temperature of the Chilled Tower.

Main Applications

① Cooling for Production Equipment

- Laser oscillators

- Electric diffusion furnaces

- Sputtering equipment

- Ultrasonic cleaning machines

- Electron microscopes

- Precision polishing machines

- High-frequency induction furnaces

- Various electric furnaces

- Paper rolls

- Flour milling rolls

- Die-casting molds

- Electric automatic welding machines

- Reaction towers

- Wastewater temperature pollution prevention

- Cooling equipment for paint tanks

② Air Conditioning (Year-Round Cooling)

- Data centers

- Clean rooms

- Factory air conditioning

③ Cooling for Research Facility Equipment

- Laser oscillators

- Various research equipment

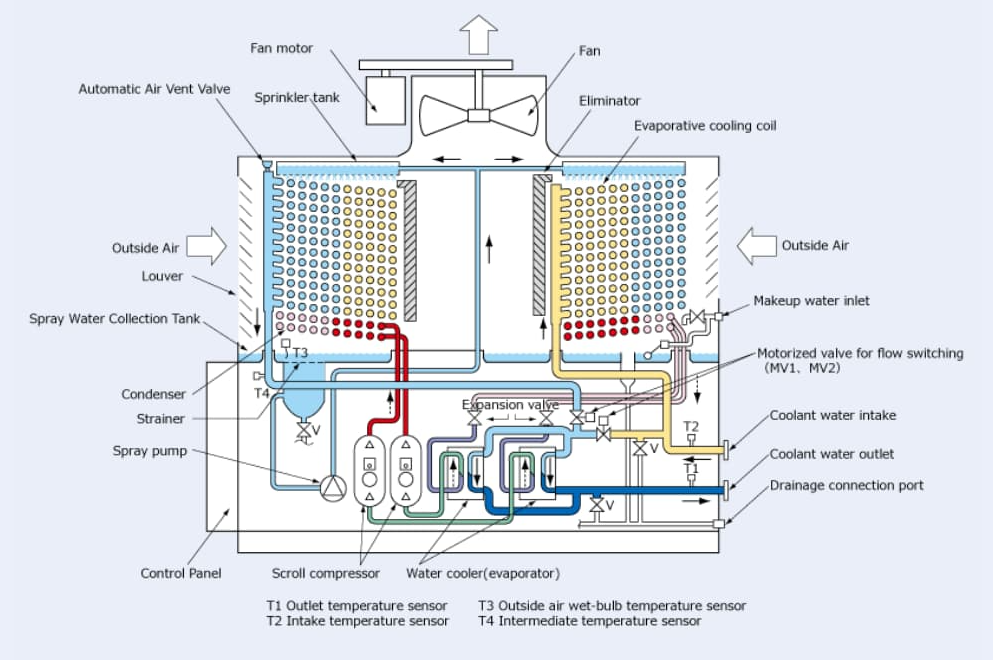

Structural Diagram

Standard Component Materials

| Category | Part Name | Material |

| Main Tower & Exterior | Louver | Aℓ(Surface Treated) |

| Platform | Checkered Steel Plate + Hot-Dip Galvanized Coating | |

| Lower Exterior Plate | Highly Corrosion-Resistant Hot-Dip Galvanized Steel Plate | |

| Bottom Plate | Highly Corrosion-Resistant Hot-Dip Galvanized Steel Plate | |

| Frame Material | Lightweight Shaped Steel with Hot-Dip Galvanized Coating | |

| Water Distribution Section | Water Distribution Tank | FRP |

| Water Distribution Pipe | PVC | |

| Water Collection Tank | FRP | |

| Pump | SUS Centrifugal Pump | |

| Fan Section | Fan | PPG |

| Casing | Steel Plate with Hot-Dip Galvanized Coating | |

| Protective Wire Mesh | Steel Wire Mesh with Hot-Dip Galvanized Coating | |

| Motor | Totally Enclosed Outdoor Type |

| Category | Part Name | Material |

| Chilled Water System | Eliminator | PVC |

| Cooling Coil | Seamless Deoxidized Copper Tube | |

| Chilled Water Piping | SUS304 | |

| Water Cooler (Evaporator) | SUS316 | |

| Valves & Fittings | SUS・BC・PVC | |

| Others | Ladder | Steel (Hot-Dip Galvanized Coating) |

| Bolts & Nuts | Steel (Zinc-Coated) & Stainless Steel (SUS) | |

| Exterior color | Lower Machinery Room Panel : Silver (Highly Corrosion-Resistant Galvanized Steel Plate) Upper Louver : Silver (Aluminum) Blower : Silver-White (Hot-Dip Galvanized Coating, etc.) | |

Specifications

| Item (Unit) | Model | |||||

|---|---|---|---|---|---|---|

| CTS-202W1 | CTS-302W1 | CTS-402W1 | CTS-502W1 | |||

| Performance ※1 | Inlet Temperature 20°C (Cooling Capacity): kW | 68.6/80.2 | 102.3/120.3 | 136.6/160.5 | 164.0/191.9 | |

| Outlet Temperature 15°C (Chilled Water Flow Rate): m³/h | 11.8/13.8 | 17.6/20.7 | 23.5/27.6 | 28.2/33.0 | ||

| Inlet Temperature 25°C (Cooling Capacity): kW | 80.2/92.1 | 120.3/138.1 | 160.5/184.2 | 191.9/223.3 | ||

| Outlet Temperature 20°C (Chilled Water Flow Rate): m³/h | 13.8/15.8 | 20.7/23.8 | 27.6/31.7 | 33.0/38.4 | ||

| Inlet Temperature 35°C (Cooling Capacity): kW | 144.2/153.5 | 215.1/230.2 | 287.2/307.0 | 331.4/359.3 | ||

| Outlet Temperature 25°C )Chilled Water Flow Rate): m³/h | 12.4/13.2 | 18.5/19.8 | 24.7/26.4 | 28.5/30.9 | ||

| Chilled Water Flow Range (Minimum to Maximum) → m³/h | 6~18 | 9~27 | 12~36 | 15~45 | ||

| Internal Pressure Loss Loss (Flow Rate) : kPa (at m³/h) | 87 (12) | 87 (18) | 87 (24) | 87 (30) | ||

| Legal Refrigeration Capacity : Tons | 5.78/6.88 | 8.67/10.32 | 11.56/13.76 | 14.45/17.20 | ||

| High-Pressure Gas Applicable Safety Law Classification) ※3 | 50Hz | No Manufacturing Notification Required | ||||

| 60Hz | ||||||

| Exterior | Inspection Panel, Louver: Anodized Aluminum Treatment, Main Frame, Fan, Ladder: Hot-Dip Galvanized Coating | |||||

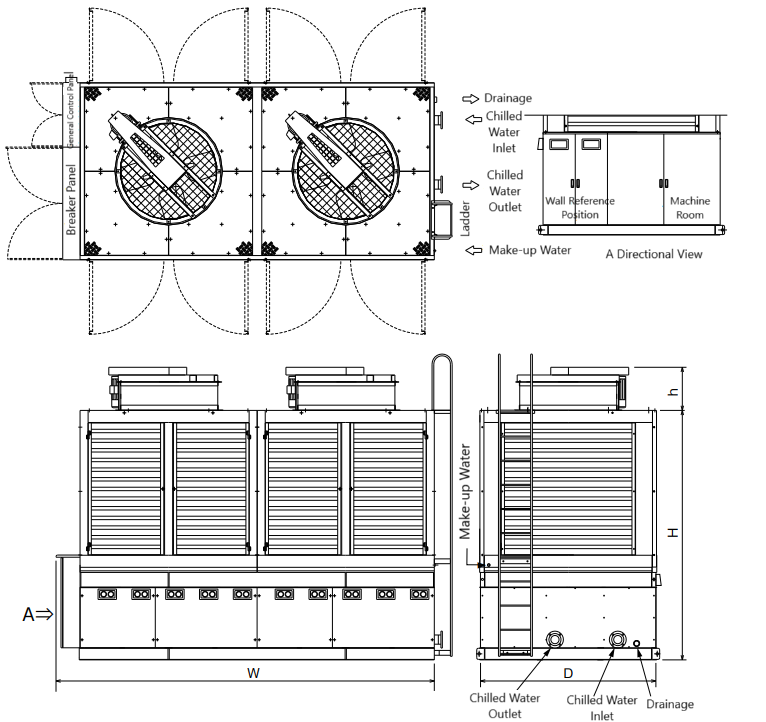

| External Dimensions | Width [W](mm) | 2,200+215 (Control Panel) | ||||

| Depth [D] (mm) | 2,200 | |||||

| Height to Shoulder [H] (mm) | 2,053 | 2,393 | 2,733 | 3,074 | ||

| Fan Height [h] (mm) | 536 | |||||

| External Diagram | A | |||||

| Fan | Model Type | Axial Fan (V-Belt Drive Type) | ||||

| External Dimensions : mm | 1200 | |||||

| Motor Output : kW (Number of Poles) × Number of Units | 3.7 (6) ×1 | 5.5 (6) ×1 | ||||

| Spray Pump | Model Type | Stainless steel centrifugal pump | ||||

| Motor Output : kW (Number of Poles) × Number of Units | 0.75 (2) ×1 | |||||

| Compressor | Model Type | Scroll-type fully enclosed electric compressor | ||||

| Motor Output : kW (Number of Poles) × Number of Units | 7.5 (2) ×2 | 7.5 (2) ×3 | 7.5 (2) ×4 | 7.5 (2) ×5 | ||

| Refrigerant Control System | Externally Equalized Thermostatic Expansion Valve | |||||

| Protection Device | High-pressure protection switch, low-pressure protection switch, freeze prevention temperature switch, discharge gas overheat temperature switch, overcurrent relay | |||||

| Type of Refrigerant | R407C | |||||

| Chilled Water System Operating Pressure (Normal Use) (MPa) | Within 0.7″ or “0.7 or less | |||||

| Spray Water Supply Volume ※4″ (m³/h) | 0.3/0.3 | 0.5/0.5 | 0.6/0.7 | 0.7/0.8 | ||

| Electrical Characteristics ※5 | Power Consumption(kW) | 21/25 | 28/34 | 38/46 | 46/56 | |

| Operating Current(A) | 76/81 | 103/112 | 137/148 | 163/178 | ||

| Power Supply | Power Supply for Operation or Main Power Supply | AC3ϕ 200V 50/60Hz | ||||

| Control Power Supply | AC1ϕ 200V 50/60Hz | |||||

| Piping Dimensions | Chilled Water Inlet/Outlet | 65A JIS 10K Flange | 80A JIS 10K Flange | |||

| Make-up Water Inlet for Sprinkling | Rc 3/4 | |||||

| Drain Connection Port | Rc 2 | |||||

| Product Weight (Operating Weight) (kg) | 2,370 (3,050) | 2,840 (3,700) | 3,230 (4,250) | 3,660 (4,850) | ||

| Water Capacity | Sprinkling System (m³) | 0.34 | 0.35 | 0.36 | 0.37 | |

| Circulation System (m³) | 0.34 | 0.51 | 0.66 | 0.82 | ||

| Noise Level (2m away at 1.5m height) ※6 | dB(A) | 71 | 72 | 74 | 74 | |

| Accessories | Ladder 1 set, Vibration Isolation Pads 1 set, Strainer 1 piece | |||||

| Options | Safety fence, Ladder backrest, Automatic blow management device (conductivity control), Sprinkling system and chilled water system anti-freeze heater, etc. | |||||

- ※1 → “Performance (cooling capacity, chilled water flow rate) values are based on an outside air wet-bulb temperature of 27°C.”

- ※2 → “Please adhere to the specified chilled water flow range. If the flow rate is too low, it may lead to damage due to freezing or clogging from accumulated contaminants. If the flow rate is too high, it may cause corrosion due to excessive flow velocity.”

- ※3 → “If required by the High-Pressure Gas Safety Act, a notification for high-pressure gas production must be submitted to the prefectural governor.”

- ※4 → “The spray water supply volume is based on conditions of an outside air wet-bulb temperature of 27°C, an inlet temperature of 35°C, and an outlet temperature of 25°C (with a concentration ratio of four during blowdown).”

| CTS-602W1 | CTS-802W1 | CTS-1002W1 |

|---|---|---|

| 205.2/240.7 | 273.3/320.9 | 327.9/383.7 |

| 35.3/41.4 | 47.0/55.2 | 56.4/66.0 |

| 240.7/276.3 | 320.9/368.4 | 383.7/446.5 |

| 41.4/47.5 | 55.2/63.4 | 66.0/76.8 |

| 431.4/460.5 | 574.4/614.0 | 662.8/718.6 |

| 37.1/39.6 | 49.4/52.8 | 57.0/61.8 |

| 18~54 | 24~72 | 30~90 |

| 87 (36) | 87 (48) | 87 (60) |

| 17.34/20.64 | 23.12/27.52 | 28.90/34.40 |

| Manufacturing Report Not Required | Manufacturing Report Required | |

| 4,400+215 (Control Panel) | ||

| 2,200 | 2,200 | 2,200 |

| 2,418 | 2,758 | 3,099 |

| 536 | 536 | 536 |

| B | ||

| Axial Fan (V-Belt Drive System) | ||

| 1,200 | ||

| 3.7 (6) ×2 | 5.5 (6) ×2 | |

| Stainless Steel Centrifugal Pump | ||

| 0.75 (2) ×2 | ||

| Scroll-type Fully Enclosed Electric Compressor | ||

| 7.5 (2) ×6 | 7.5 (2) ×8 | 7.5 (2) ×10 |

| External Equalization Type Thermal Expansion Valve | ||

| High-Pressure Protection Switch, Low-Pressure Protection Switch, Freeze Prevention Temperature Switch, Discharge Gas Overheat Temperature Switch, Overcurrent Relay | ||

| R407C | ||

| Within 0.7″ or “0.7 or less | ||

| 0.9/1.0 | 1.2/1.3 | 1.4/1.6 |

| 56/68 | 76/92 | 91/111 |

| 203/221 | 271/294 | 324/354 |

| AC3ϕ 200V 50/60Hz | ||

| AC1ϕ 200V 50/60Hz | ||

| 100A JIS10K Flange | ||

| Rc 3/4 | ||

| Rc 2 | ||

| 5,400 (7,200) | 6,320 (8,500) | 6,980 (9,500) |

| 0.71 | 0.73 | 0.75 |

| 1.05 | 1.45 | 1.77 |

| 74 | 76 | 76 |

| Ladder 1 Set, Vibration Isolation Pads 1 Set, Strainer 1 Piece | ||

| Safety Fence, Ladder Backrest, Automatic Blow Management Device (Conductivity Control) | ||

| Sprinkling System and Chilled Water System Anti-Freeze Heater, etc. | ||

- ※5 … The electrical characteristics (power consumption, operating current) indicate values under the conditions of an ambient wet-bulb temperature of 27°C, an inlet temperature of 35°C, and an outlet temperature of 25°C. Additionally, the transformer capacity and wiring capacity should be at least 1.2 times the power consumption and operating current to account for variations in operating conditions.

- ※6 … The noise level represents the measured value (A-scale) in a non-reverberant environment. In actual installation conditions, surrounding noise and reflections may cause variations of approximately ±3 dB(A).

Figure A

Note: Please ensure a clearance of at least 1.5 meters around the entire perimeter for service space.

Figure B

Note: Please ensure a clearance of at least 1.5 meters around the entire perimeter for service space.

Related Products

-

Kuwana Metals SAM PS200 Series Pressure-Based PI Mass Flow Controller

-

Kuwana Metals Aera Transformer Digital Mass Flow Products

-

Kuwana Metals Aera FC-R7800 Series Mass Flow Controller

-

Kuwana Metals SAM SFC1480FX / SFC2480FX Series Mass Flow Controller

-

Kuwana Metals FCMB35-10/FCD-S/SCS Series/WCB/A105/F304/PE80 Valves

-

Kuwana Metals A Series Chilled Tower