Kyodo Yushi

Kyodo Yushi FR Grease L

Product Made in Japan

Manufacturer : Kyodo Yushi

Model: FR Grease L

In process industry, a demand for flame retardant grease is growing every year. In the context of the needs, FR GREASE L was developed as fire resistant lubricating grease. The most notable features of the innovative grease are resistance to ignition and, even if ignited, prevents fire from spreading as it ceases burning. It minimizes damage caused by fire and fire spread.

Characteristics of FR Grease L

- 1.Prevention of fire spreading

- Possesses a property of stopping itself from burning once the fire source is removed. (JP Pat. No. 4268789)

- 2.Ignition resistance

- High in ignition temperature. Even putting a steel ball of 900°C into it won’t set the grease on fire.

- 3.Excellent load carrying capacity

- Provides load carrying capacity equivalent to EP lithium grease.

- 4.Excellent pumpability

- Being low in apparent viscosity and resistant to plugging, the grease is applicable to centralized lubricating systems.

Main applications and applicable components

- Bearings used for incinerators, drying ovens and air-heating furnaces

- Steel facilities which require fire prevention measures

- Lubrication for other industrial machinery and facilities which hold fire sources such as for welding, hardening, casting process

Typical Property

| Test item | Test method | Test results | |

|---|---|---|---|

| Thickener | – | Lithium soap | |

| Base oil | – | Mineral oil | |

| Working penetration | ASTM D 217 | No.0: 375 No.1: 320 | |

| Service temperature range | – | −10°C – 130°C | |

Prevention of fire spreading

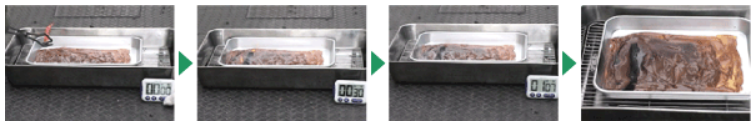

- Comparison test on fire spreading between common EP lithium grease and FR Grease L. In the case of common EP lithium grease, the fire spreads all over the grease. While FR Grease case, it self-extinguished in about a minute. After burning, common EP lithium greases become liquid. FR Grease L remains in grease state.

- Test method

- Pour 200g grease in an aluminum pallet and put a peace of steel (15cm) heated at around 950°C into it.

- Measure the time taken for fire to spread, to be put out, then observe the state of the residual grease.

Comparison test on fire spreading (based on a scenario of an ignition after a scale jumping into grease)

EP lithium grease (General grease of Kyodo Yushi)

After ignition, the fire gained the force and spread over time. (30sec. to 3min.) As it kept burning without dying down, the grease was extinguished forcibly (at 4min. 7sec.). The grease resulted in liquefied.

FR Grease L

After ignition, the fire died down by itself in about one minute. The grease remained in grease state.

Load carrying capacity

- FR Grease L has load carrying capacity higher than EP lithium greases do.

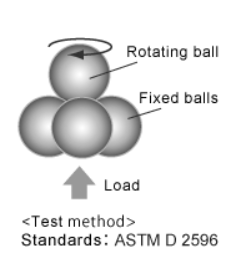

High-Speed Four-Ball EP <ASTM D 2596>

- FR Grease L has load carrying capacity higher than EP lithium greases do.

High-Speed Four-Ball EP <ASTM D 2596>

Test method FR Grease L EP lithium grease(General grease of Kyodo Yushi) L.N.S.L.

(Last Non-Seizure Load)ASTM D 2596 981 981 W.P.

(Weld Point)2452 2452 L.W.I.

(Load-Wear Index)442 450

- ※The above values are typical properties and we cannot guarantee the applicability of this information in any individual situation. Information regarding the application and service temperature range or typical property values are provided as a guide in selecting the appropriate grease. It is recommended that the user makes its own assessment and determination of the safety and suitability of the product performance/properties for the intended purposes prior to use.

- ※Safety Data Sheet (SDS) of the product should be consulted prior to the use.

- ※The information contained herein is subject to change without notice.

- ※All images used are for illustrative purposes only. (excluding test results).