Kyodo Yushi

Kyodo Yushi Palmax RBG Grease

Product Made in Japan

Manufacturer : Kyodo Yushi

Model: Palmax RBG

Roll neck bearing requires a lubrication condition under so-called high PV range since sliding condition between a roller end surface and the flange section of an inner race is very severe.

PALMAX RBG is able to control oil separation through temperature conditions. Providing a function similar to oil lubrication, it contributes to extend service life of a bearing operating at high velocity or high-V. Suitable for sealed bearings operating at high velocity.

Characteristics of Palmax RBG

- 1.Lubricity

- Having properties of oil separation and return, the grease has performance similar to oil lubrication and is suitable for bearings with high PV.

- 2.High in adhesion

- Its high adhesion to bearings restrains the grease from spattering and prevents failure in lubrication of bearings caused by grease loss.

- 3.Water resistance

- Excellent shear stability in the presence of water prevents failure in lubrication of bearings caused by grease softening and leakage.

- 4.Rust prevention

- Even in the presence of industrial water, the grease offers excellent rust-preventive property and prevents bearings from being damaged by corrosion during storage.

Main applications and applicable components

- Roll neck bearings of rolling equipment

Typical Property

| Test item | Test method | Test results | |

|---|---|---|---|

| Thickener | – | Special-lithium complex | |

| Base oil | – | Mineral oil | |

| Working penetration | ASTM D 217 | 300 | |

| Service temperature range | – | −10°C – 150°C | |

Lubricity (Property similar to oil lubrication)

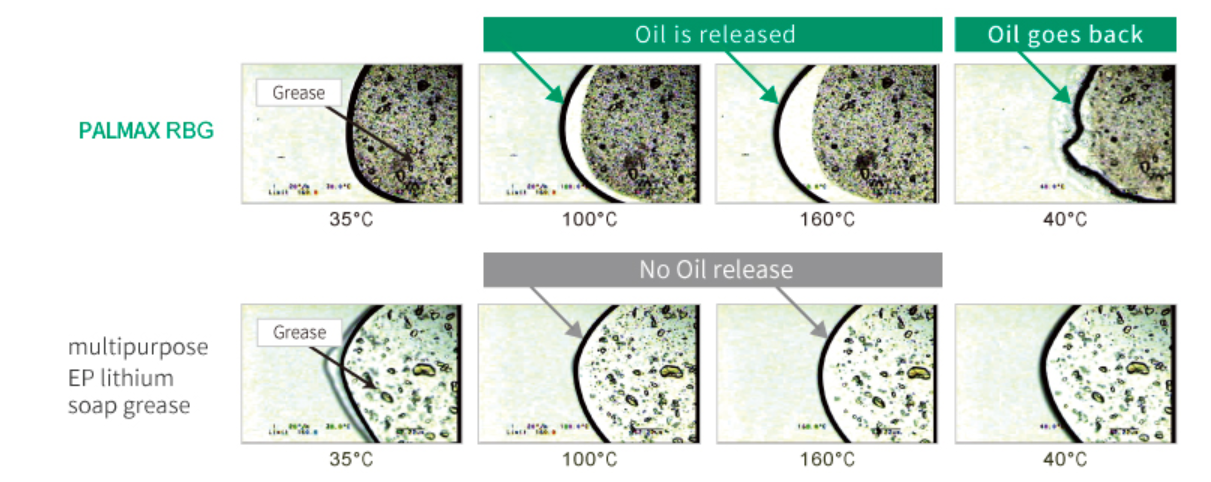

- PALMAX RBG has a property: When temperature rises, the grease bleeds oil and when temperature drops, the free oil returns back to the grease. Owing to this property, the grease is superior in oil film forming at high temperature (high-speed, high-load), offering good lubricity.

Comparison with oil release from our multipurpose EP lithium soap grease and PALMAX RBG

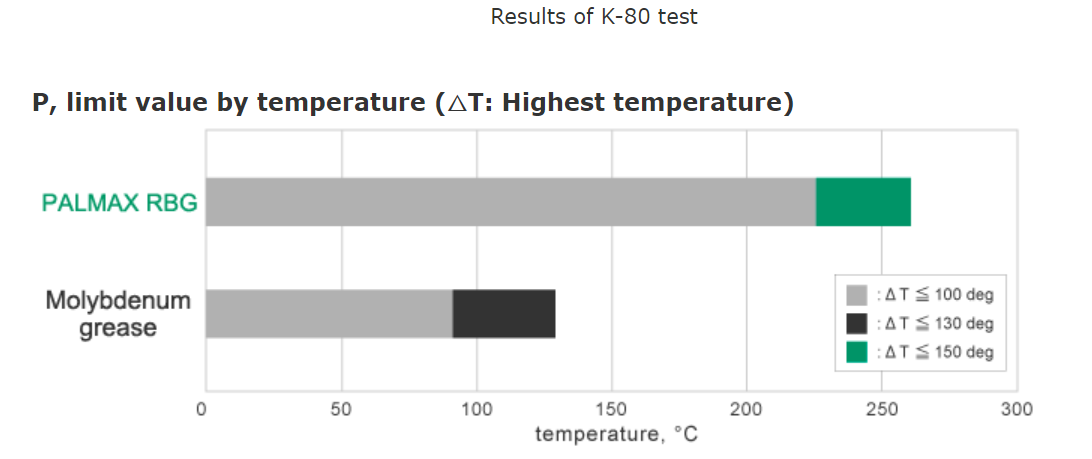

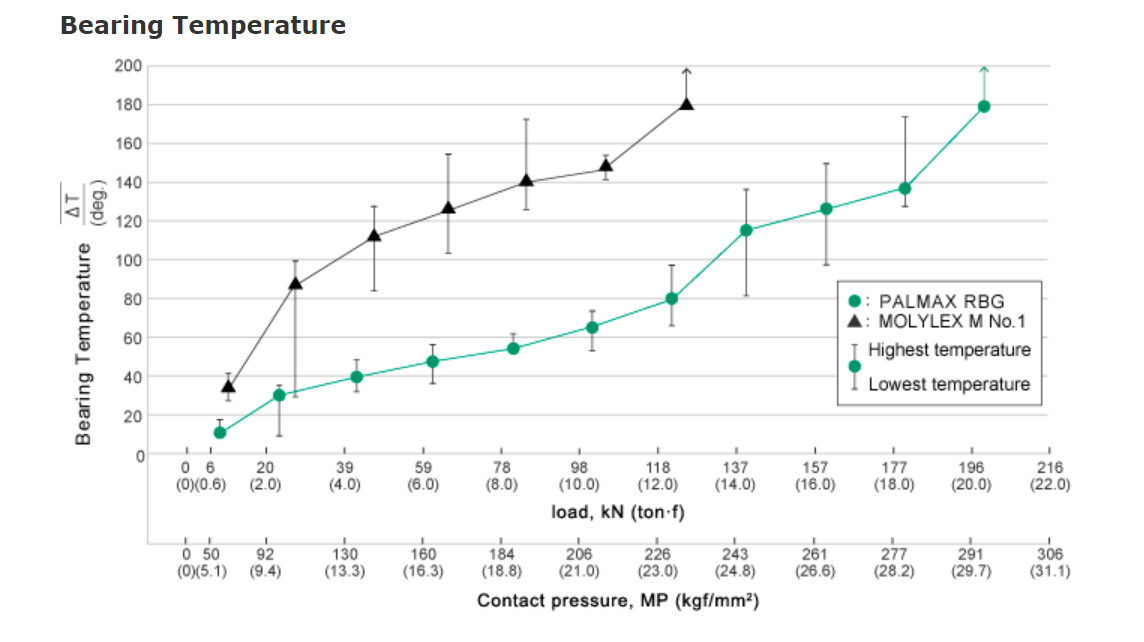

PV property

- Test method

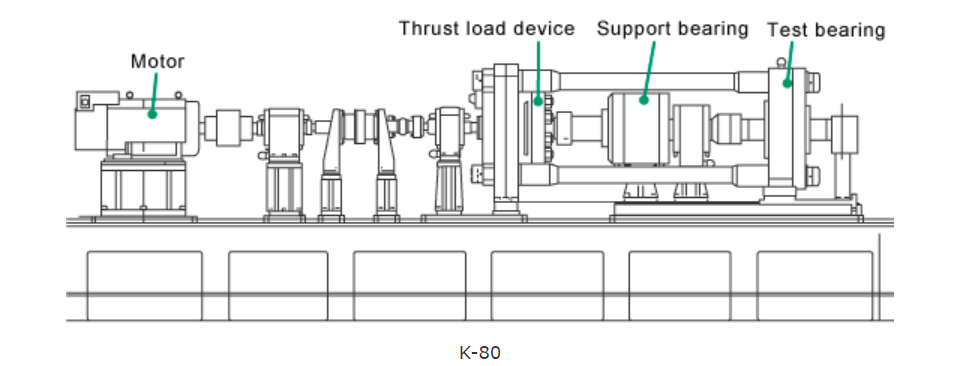

Test rig: K-80 (See the picture shown below)

Test bearing: Steep angle tapered roller bearing (Bore 80mm)

Amount of grease filled: 500g (Bearing box volume 100%)

Thrust loading: Gradual increase starting from 5.9kN (0.6ton)

Rotational speed: 1193 rpm (Fixed)

V: 1.0m/s (Fixed)

Test method: Start the test with the condition―rotational speed 1193rpm (V = 1.0m/s), load 5.9kN { 0.6ton f } ( P = 50MP { 5.1kgf/mm2 }). Then gradually raise the load every one hour to continue the testing until the rise in temperature (ΔT) exceeds 180deg.*△T = Bearing temperature − room temperature

Excellent rust-prevention

- Even in the presence of industrial water, the grease keeps excellent rust-prevention to prevent bearings from being damaged by corrosion during storage.

A.Test of bearing rust prevention 80℃×24h

B.Test of high-load bearing rust prevention 80℃×24h

C.Test of bearing on saltwater rust prevention 25℃×24h

D.Test of Emcor rust prevention (Industrial water)

25℃×168h(Standard corrosive water)

25℃×168hASTM D 1743-73 ASTM D 1743-73 mod. ASTM D 1743-73 mod. IP220mod. IP220mod. #1 #1 #1 0 0

Criteria

#1:No corrosion

#2:Three corrosion sites or less

#3:Severer corrosion than #2Criteria

0: No corrosion

1: Three corrosion sites or less

2: Rust on raceway surface: 1% and under

3: Rust on raceway surface: 1 − 5%

4: Rust on raceway surface: 5 − 10%

5: Rust on raceway surface: 10% and over- ※The above values are typical properties and we cannot guarantee the applicability of this information in any individual situation. Information regarding the application and service temperature range or typical property values are provided as a guide in selecting the appropriate grease. It is recommended that the user makes its own assessment and determination of the safety and suitability of the product performance/properties for the intended purposes prior to use.

- ※Safety Data Sheet (SDS) of the product should be consulted prior to the use.

- ※The information contained herein is subject to change without notice.

- ※All images used are for illustrative purposes only. (excluding test results).

- Test method