Kyodo Yushi

Kyodo Yushi Powerlite WR Grease

Product Made in Japan

Manufacturer : Kyodo Yushi

Model: Powerlite WR

POWERLITE WR is a next generation environment-responsive grease designed for applications under harsh conditions where water resistance and load carrying capacity are imperative.

It uses purified mineral oil as its base oil and calcium sulfonate complex as its thickener. Containing no heavy metal like molybdenum, the next generation eco-friendly grease is superior in water resistance, rust prevention, load carrying capacity and shear stability.

Characteristics of Powerlite WR

- 1.Water resistance

- Its prominent adhesion brings resistance to washing, offering exceptional water resistance.

- 2.Rust prevention

- Calcium sulfonate complex, the thickener of the grease, is widely used for anti-corrosion detergent for engine oils, providing excellent sustainable rust prevention.

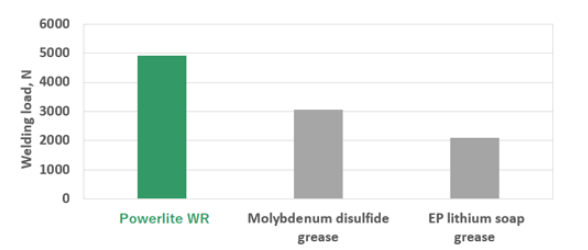

- 3.Load carrying capacity

- As the thickener ingredient serves as solid lubricant, having wear resistance and EP lubricity higher two-times or more than those of molybdenum disulfide.

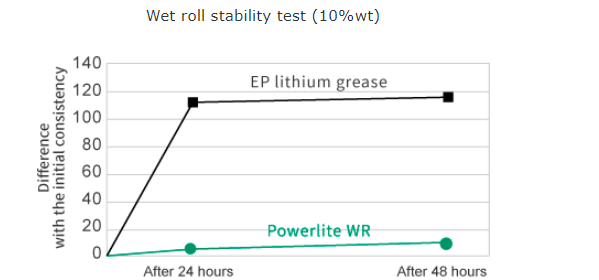

- 4.Shear stability

- Owing to the thickener contained plentifully, the grease changes little in consistency even in moisture state, resisting to softening and leakage derived from mechanical shear.

- 5.Environmental friendliness

- It is eco-friendly, easier to be disposed of and not contaminate cooling water as the grease contains no heavy metal and sinks under water.

Main Applications and Applicable Components

- Work roll bearings of mills at ironworks

- Bearings of machinery equipment at paper mills

- Industrial machinery (agricultural machines, construction machines, etc.)

- Facilities for dams, hydropower generation and flood control, etc.

Typical Property

| Test item | Test method | Test results | |

|---|---|---|---|

| Thickener | – | Ca-sulfonate complex | |

| Base oil | – | Mineral oil | |

| Working penetration | ASTM D 217 | No.0: 370 No.1: 325 No.2: 280 | |

| Service temperature range | – | −20°C – 180°C | |

Load carrying capacity

- Excellent load carrying capacity which is superior to that of greases containing molybdenum disulfide. Optimum choice for lubrication points where high-load and shock loading are inevitable.

Comparison of load carrying capacity in high-speed four-ball EP test <ASTM D 2596>

Shear stability

- POWERLITE WR changes little in consistency even in moisture state, exceling in sealing performance with little softening and leakage.

Wet roll stability test (10%wt)

- ※The above values are typical properties and we cannot guarantee the applicability of this information in any individual situation. Information regarding the application and service temperature range or typical property values are provided as a guide in selecting the appropriate grease. It is recommended that the user makes its own assessment and determination of the safety and suitability of the product performance/properties for the intended purposes prior to use.

- ※Safety Data Sheet (SDS) of the product should be consulted prior to the use.

- ※The information contained herein is subject to change without notice.

- ※All images used are for illustrative purposes only. (excluding test results).