Kyodo Yushi

Kyodo Yushi Spacelube MU Next-Generation Vacuum Grease

Product Made in Japan

Manufacturer: Kyodo Yushi

Model: Spacelube MU

Fluorinated grease has been widely used for space and vacuum applications, but they are degraded by exposure to radiation. Spacelube series were developed to offer solutions for this problem, as well as for the friction and wear encountered in a vacuum environment.

Spacelube is the only Japanese grease product, whose long life and excellent lubricity in the space environment have been demonstrated by the two-year experiment on SERVIS-1, the Space Environment Reliability Verification Integrated System. With the approval of JAXA (Japan Aerospace Exploration Agency), Spacelube was adopted for Venus climate orbiter called “Akatsuki,” and has since been used for space satellites.

Characteristics of Spacelube MU

- 1.Low vapour pressure

- The same low vapour pressure characteristics as fluorinated grease and very low outgassing from base oil decomposition ensure minimal contamination in vacuum systems.

- 2.Long Life

- Offers very long life because, unlike fluorine oil, the base oil does not degrade by exposure to radiations or react with iron to form Lewis acid and metal fluorides, which acts as a catalyst for decomposition.

- 3.Lubricity

- Offers excellent lubricity compared to fluorinated grease.

- 4.Easy grease removal

- The compatibility of hydrocarbon base oil with other types of fluids allows easy removal of the grease without CFC or other solvents.

Main applications and applicable components

- Lubrication of apparatus used in vacuum environment such as semiconductor manufacturing equipment

Typical Property

| Test item | Test method | Test results | |

|---|---|---|---|

| Thickener | – | Urea | |

| Base oil | – | Cyclopentane oil | |

| Working penetration | ASTM D 217 | 300 | |

| Service temperature range | – | −40°C – 180°C | |

Friction/Wear Properties

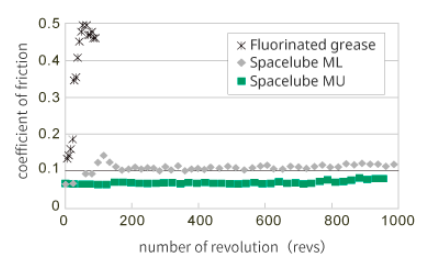

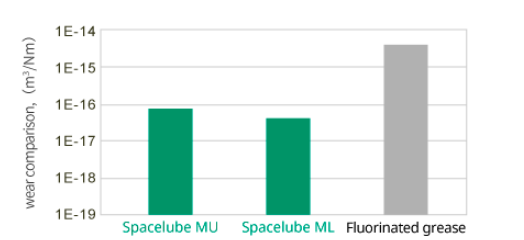

- Spacelube exhibits consistently low friction coefficients and reduced wear in comparison to the fluorinated grease.

Coefficient of friction

Wear comparison

Radiation Resistance

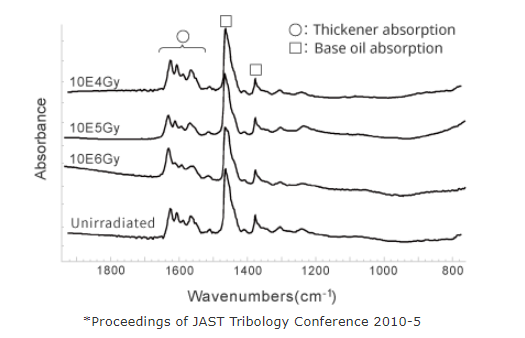

- Absence of a significant change in the IR spectra regardless of the irradiance level indicates good resistance of the grease against electron beam.

IR spectra after exposure to radiations

Outgassing

- Spacelube conforms to NASA’s outgassing specification.

- Test Condition

- Vacuum degree: 7.0×10-3Pa or lower

- heater bar temp.: 125±1°C

- cooling plate temp.: 25±1°C

- equipment running time: 24h

- initial specimen weight: 250 – 252mg

Outgassing characteristics

| Spacelube ML | Spacelube MU | Recommended by NASA | |

|---|---|---|---|

| TML (Total Mass Loss), % | 0.143 ± 0.015 | 0.570 ± 0.026 | 1 or lower |

| CVCM (Collected Volatile Condensable Materials), % | 0.007 ± 0.000 | 0.085 ± 0.002 | 0.1 or lower |

- ※The above values are typical properties and we cannot guarantee the applicability of this information in any individual situation. Information regarding the application and service temperature range or typical property values are provided as a guide in selecting the appropriate grease. It is recommended that the user makes its own assessment and determination of the safety and suitability of the product performance/properties for the intended purposes prior to use.

- ※Safety Data Sheet (SDS) of the product should be consulted prior to the use.

- ※The information contained herein is subject to change without notice.

- ※All images used are for illustrative purposes only. (excluding test results).