Japan, Matsuda Seiki

Matsuda Seiki Automatic Pipe Cutting Machine

Product: Made in Japan

Manufacturer: Matsuda Seiki

Model: Automatic Pipe Cutting

The semi-order pipe-cutting machine is expertly designed to automatically cut the target workpiece set on the jig, utilizing a cutting wheel for precision.

This innovative approach ensures minimal burrs during the cutting process, providing a smooth finish.

Reflecting the diverse needs of our customers, this machine is a testament to our commitment to customization and flexibility.

Furthermore, it is worth noting that the capability to manufacture a pipe-cutting machine tailored to specific conditions, beyond the ones initially mentioned, is also available.

This adaptability underscores our dedication to meeting and exceeding customer expectations, by offering solutions that are not only efficient but also versatile.

Work condition

Type EGR-TUBE

Appearance recording Pipe material (φ17.0)

Processing location Both ends

Material SUS429M

Processing time 40 seconds (simultaneous processing of 2 pipes) In addition, we design and manufacture many measuring devices and dedicated machines.

If you can do this, we will make the equipment to meet your needs.

This is a semi-order pipe-cutting machine that reflects the customer’s request.

It is also possible to manufacture a pipe-cutting machine with conditions other than the following.

Basic information

Spindle

Spindle motor 0.75kw 2P

Transmission belt

Timing belt pulley ratio 2:1 (speed increase)

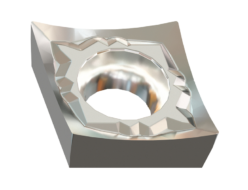

The WA-CUT 230×1.0×25.4 magnet type features a wide range of operational capabilities, including a magnet rotation speed with a setting range from 690 to 4700rpm. Additionally, its magnet peripheral speed can be adjusted within a setting range of 370 to 3400m/min, offering extensive versatility for various cutting needs. This flexibility in speed settings ensures that the machine can be tailored to suit specific materials and cutting requirements, enhancing both efficiency and precision in industrial applications. Magnet peripheral speed Setting range 370~3400m/min

X Slide

Slide movement distance Max 300mm

Slide drive system Servo motor

Detection function Machining position & original position confirmation (cylinder center)

Y

Slide movement distance Max 90mm

Slide drive system Servo motor

Net polishing time 40 seconds or less (simultaneous processing of 2)

Column

Left and right movement Distance 26 mm

Movement method Manual

Others

Gross weight 1.2ton

Power consumption 2.5kva