Japan, MAXPULL

Maxpull Manual winch with built-in stopper (SI type)

Made in Japan

Manufacturer: Maxpull

Model: GM-1-SI type / GM-3-SI type / GM-5-SI type / GM-10-SI type / GM-20-SI type / GM-30-SI type

Features

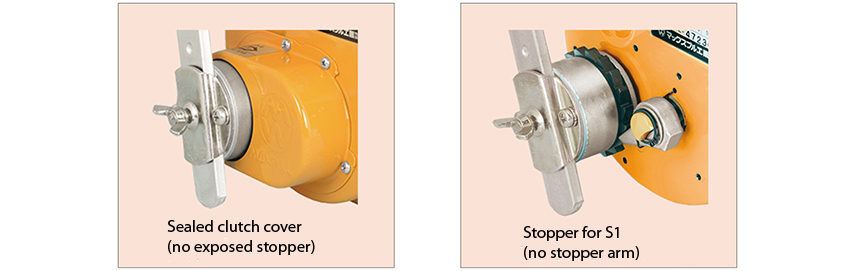

Please select it for use in places where there is a risk of erroneous operation if the stopper arm that can release the brake is outside (schools, public facilities, places where an unspecified number of people enter and leave, etc.). Since the stopper mechanism is built into the special sealed clutch cover, the lifting and lowering work can be safely performed without any danger due to erroneous operation.

It is possible to manufacture for all stainless steel and all steel models. When ordering, please specify, for example, GM-5-SI, ESB-5-SI.

Easy operability

Due to its high mechanical efficiency, the manual load during operation is very light compared to winches manufactured by other companies, making work easier. Due to its compact design, it is lightweight and very convenient to carry. In addition, the body can be easily fixed with the prescribed bolts. Another great feature is that each part is made by press processing, and the whole is assembled with bolts, so it can be easily disassembled. Even in the case of repair, anyone can easily repair and assemble by simply purchasing the parts and following the instruction manual.

Outstanding durability

All bearings use ball bearings from leading manufacturers. It is light to wind up and exhibits outstanding strength against wear. In addition, the speed reducer employs our unique shifting method gear that has been subjected to special heat treatment, allowing work to be performed with ease. The mechanical brake also has a mechanism that allows you to freely adjust the gap, so it has excellent durability. In addition, the surface is completely prepped and baked on, so it is resistant to rust and can be used in any work location.

Safety you can trust

Carefully selected materials and advanced design and technology boast an extremely high level of safety. In particular, the parts where the load is applied intensively are combined with precision press-processed ribs or double plates to further increase strength. A double safety mechanism is adopted for the mechanical brake, so even if an impact is applied to the claw arm, no braking will occur. In addition, the wire rope is fixed to the drum with a double safety structure using a special drum that ensures waste winding. Wire rope ends can be fixed to the drum easily and securely with the included hexagonal L-shaped wrench. All are highly reliable and safe designs unique to our company.

Safety design when brake release is not required

It is suitable for use mainly in sites used by an unspecified number of people (lifting and lowering various nets used in school physical education, lifting baskets and goal boards, lifting and lowering stage equipment, etc.). The stopper arm that releases the brake to allow the drum to idle is eliminated, and the stopper mechanism is built into the closed clutch cover. can work.

Specifications

| Model | GM-1-SI type | GM-3-SI type | GM-5-SI type | GM-10-SI type | GM-20-SI type | GM-30-SI type |

| wire rope tensile force | 980N (100kgf) φ5 wire rope winding 4th layer standard |

2940N (300kgf) φ6 wire rope winding 5th layer standard |

4900N (500kgf) φ6 wire rope winding 5th layer standard |

9800N (1000kgf) φ8 wire rope winding 3rd layer standard |

19600N (2000kgf) 9φ wire rope winding 3rd layer standard |

29400N (3000kgf) φ12 wire rope winding 3rd layer standard |

| Wire rope capacity | φ5mm×35m (6 layers winding) | φ6×32m (6 layers winding) | φ6×40m (6 layers winding) | φ8×35m (5 layers winding) | φ9×38m (5 layers winding) | φ12×35m (4 layers winding) |

| Deceleration ratio | 1/1 | 1/6.25 | 1/8.9 | 1/12.6 | 1/20 early winding 1/4 | 1/35.5 |

| Handle operating force | 1st layer: 143N (14.6kgf) 3rd layer: 187N (19.0kgf) 4th layer: 208N (21.2kgf) |

1st layer: 76N (7.7kgf) 3rd layer: 103N (10.5kgf) 5th layer: 131N (13.3kgf) |

1st layer: 109N (11.1kgf) 3rd layer: 142N (14.4kgf) 5th layer: 174N (17.7kgf) |

1st layer: 133N (13.5kgf) 2nd layer: 157N (16.0kgf) 3rd layer: 182N (18.5kgf) |

1st layer: 157N (16.0kgf) 2nd layer: 186N (18.9kgf) 3rd layer: 214N (21.8kgf) |

1st layer: 137N (13.9kgf) 2nd layer: 169N (17.2kgf) 3rd layer: 201N (20.5kgf) |

| Handle length (effective maximum) |

250mm | 250mm | 250mm | 300mm | 370mm | 370mm |

| Weight (Body + Handle) | 7.2kg | 14.1kg | 15.4kg | 16.4kg | 28.2kg | 37.7kg |

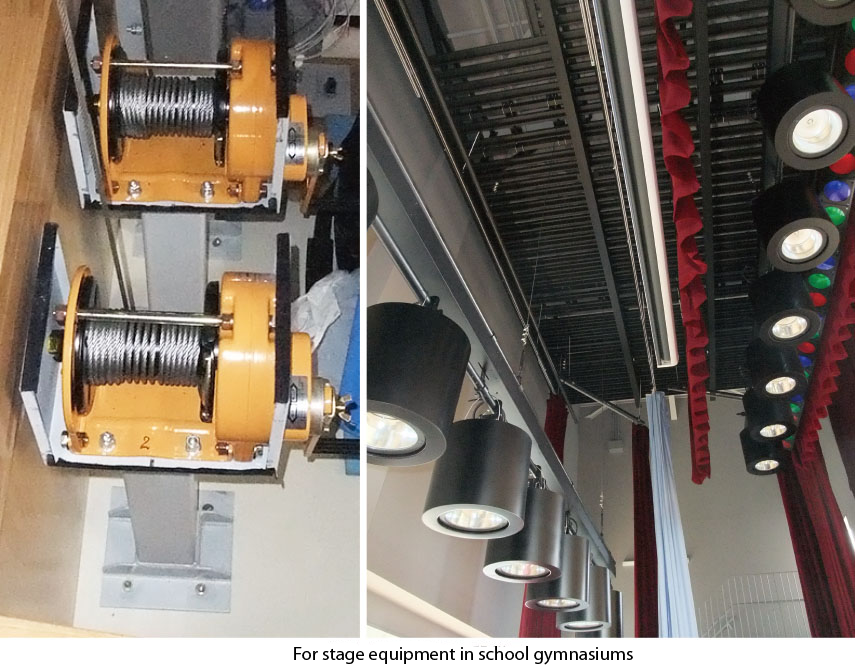

Example of SI type usage site

Related Products

-

Chiyoda Seiki Cased Stainless Steel Cleaning Needle

-

OSC92OT112 6 – Component Load Cell For Buildings

-

Chiyoda Tsusho CSE-01/02/02H/03/04 SHOULDER HEAD (CSE Type)

-

Kokosha LED Wall Light

-

SAKUSAKU 4SS-30D 2.5S Carbide Square End Mill 4-Flute

-

Eagle Jack (Konno Corporation) ED-25C-PG-75kM-25 Hydraulic Bottle Jack