Japan, MAXPULL

Maxpull special electric winch

Product made in Japan

Manufacturer: Maxpull

Model: DWG type/PW type/BFH type/SUD type/STB type

Features

Special winches account for 35% of the total production of Maxpull winches. Special electric winches that are full of personality tailored to the customer’s site and usage are playing an active role in various fields. A wide variety of applications, capabilities, methods, sizes, and control methods. Compatible with different voltages (400V). We want to move our customers with creative designs. > will respond.

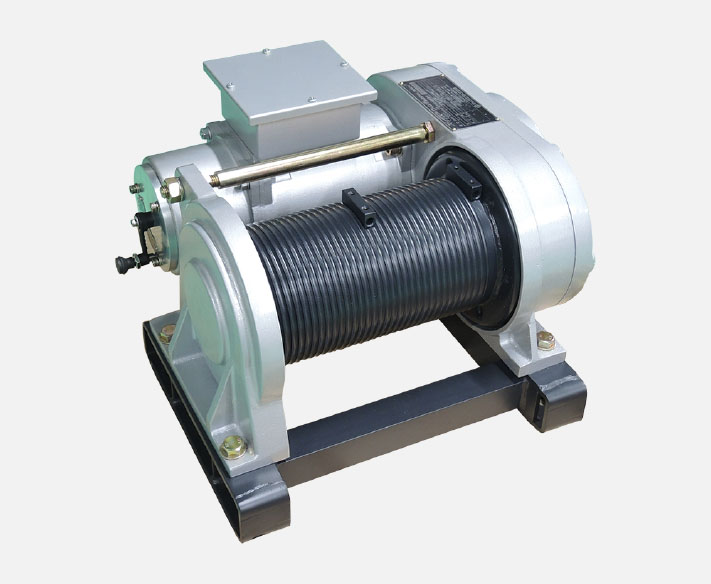

DWG type

2 wire rope pulls, grooved drum specification Electric winch

can be lifted horizontally without lifting one side.

It is useful when you want to horizontally move long objects such as lids, piers, gates and batons. Two wire ropes can be attached, and an equal amount of wire ropes are wound synchronously along the wire groove dug on the drum surface, so long Loads can be slantwise. It can be lifted, opened and closed horizontally. The wire groove is also useful for reducing irregular winding of the wire rope and shortening the fleet angle (distance to the first pulley).

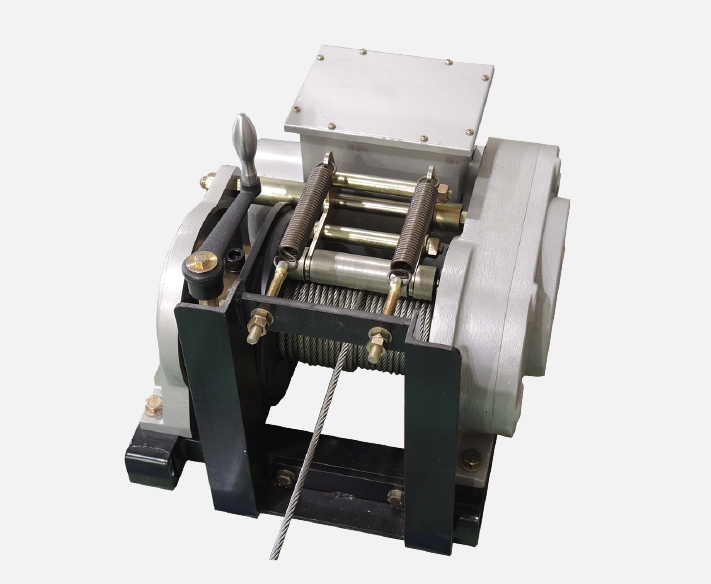

PW type

Equipped with wire holding roller Prevents wire rope loosening that causes electric winch random winding.

If the tension of the wire rope is lost when the suspended load lands on the ground or is being towed horizontally, the wire rope wound around the drum will instantly loosen due to the reaction force, causing the wire rope to swell and cause random winding. By installing a wire holding roller, the looseness and bulging of the wire is suppressed by the rotating roller, preventing irregular winding. It is an option often used for

” BMW three-phase 200V dog clutch series “.

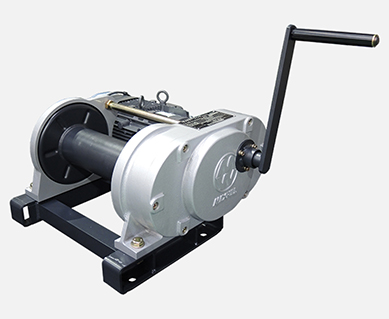

BFH type

Equipped with brake release function and handle operation function Electric winch

Moves the load to a safe place even if power is lost in an emergency such as a power outage.

In a typical electric winch, when power is cut off in an emergency such as a power outage, the brake closes and the winch stops. Even in such a case, the BFH model can handle cargo by operating the handle after releasing the brake . if it becomes impossible to lift or tow the load, the load can be moved to the desired position by manual operation using the handle . and closing lids that must be used even in emergencies.

SUD type

Stainless steel drum specification

Prevents corrosion of the electric winch drum and reduces strength.

There are many cargo handling operations performed by a winch, such as towing a substitute ship, opening and closing water gates and dust collectors, raising and lowering underwater equipment, and moving objects on and in the water. During such work, moisture adhering to the wire rope causes rust on the steel winch drum, which reduces the strength of the metal and poses a safety hazard.

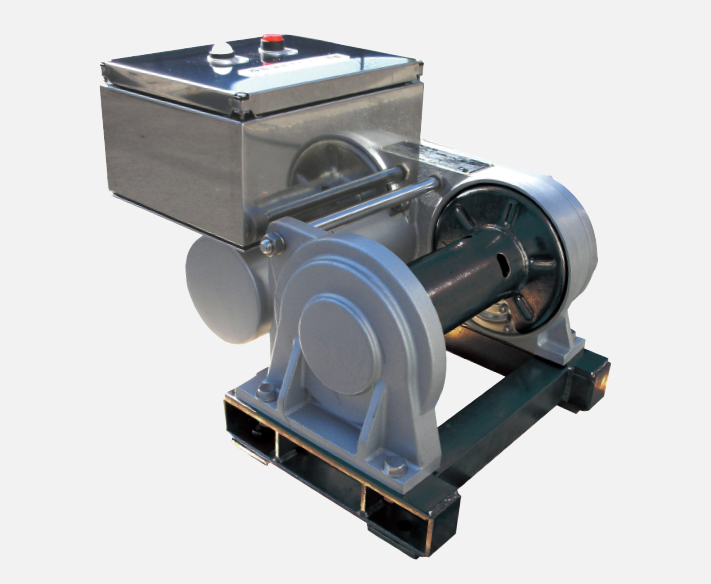

STB type

Control panel integrated type

There is no problem with the installation location of the electric winch control panel.

The STB type is an option that integrates the control panel into the back of the electric winch. When using a combination of an electric winch and a control panel, the control panel is generally wall-mounted or made self-supporting. the STB type is designed to be small by incorporating the internal circuit three-dimensionally so that it can be held in the electric winch.