Miura

Miura Biogas Treatment Equipment

Manufacturer: Miura Chemical Equipment Co., Ltd.

MIURA optimally designs each dry desulfurization system to match specific customer needs, and we carefully consider factors such as gas volume, hydrogen sulfide concentration, desulfurization agent replacement cycle, and available installation space. We can also handle the design and manufacture of ancillary maintenance stands and hoisting equipment, as well as the operation of desulfurization agent injection.

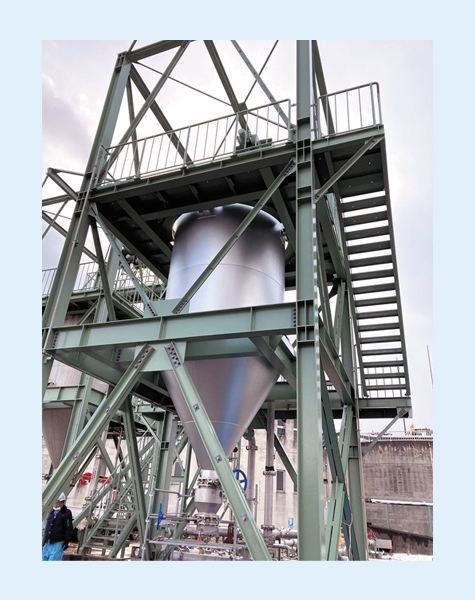

Dry desulfurization equipment

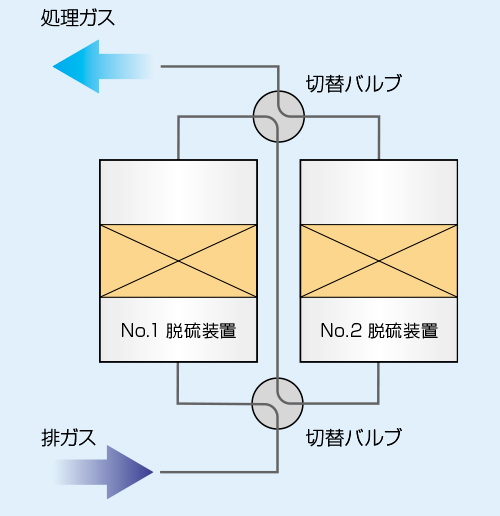

Intermittent

This simple system consists of a cylindrical device filled with a desulfurization agent. The system removes H₂S by passing the biogas directly through the desulfurizing agent, so the gas contacts the agent efficiently. In intermittent systems, the operator installs multiple desulfurization units and then replaces the agent in the unit that currently stops the gas flow, thereby maintaining stable and continuous treatment.

Applications : This system removes H2S (hydrogen sulfide)

from biogas generated by the methane fermentation of organic matter, such as sewage sludge, food waste, and livestock manure.

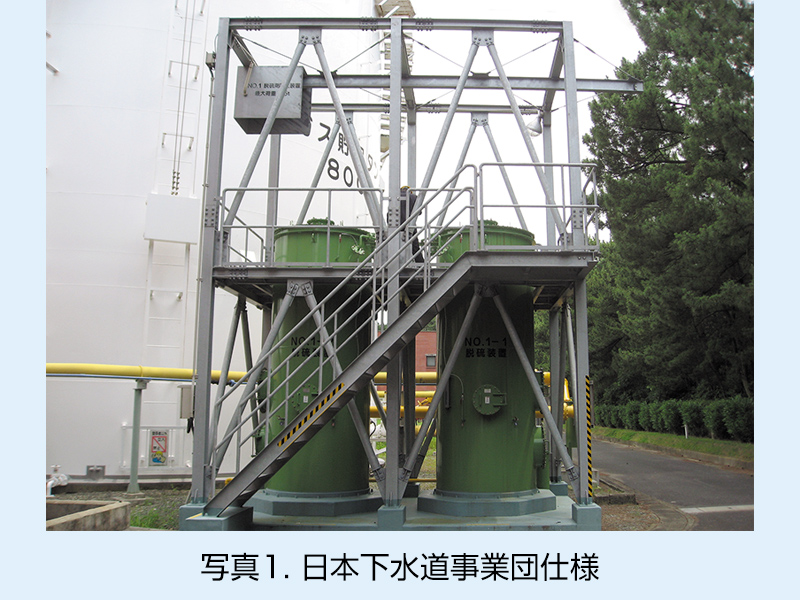

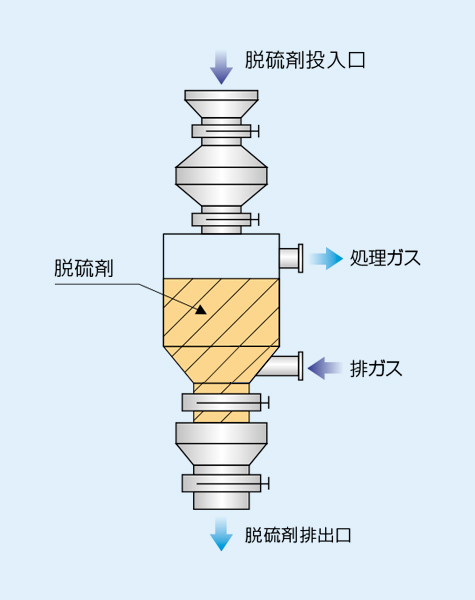

Continuous type

The continuous desulfurization equipment is equipped with two knife gate valves at the desulfurization agent inlet and outlet.

This allows the desulfurization agent to be replaced without shutting off the gas, even with a single desulfurization equipment.

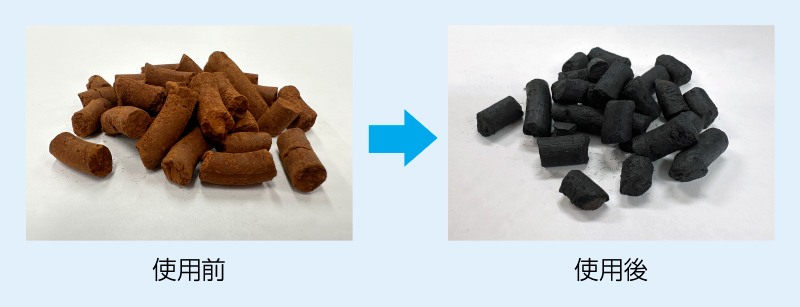

Desulfurization agent (iron oxide)

Iron oxide, the main component of desulfurization agent, removes H2S

. After H2S is removed, the iron oxide becomes iron sulfide. The color of the desulfurization agent changes before and after use. The type and particle size of the agent are selected according to the application .

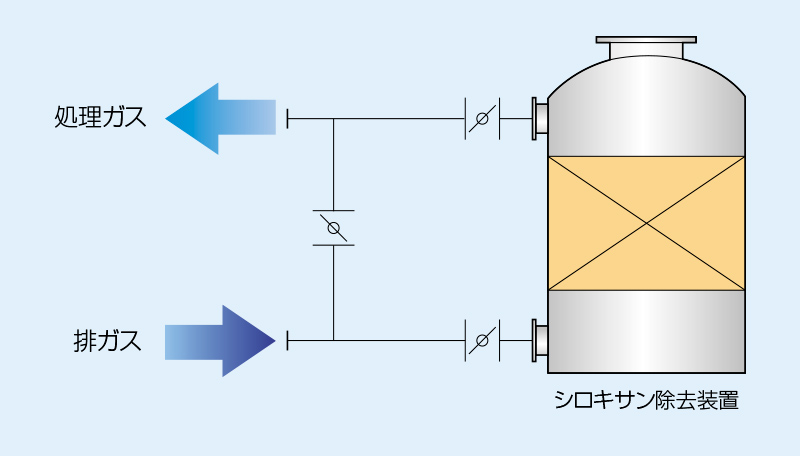

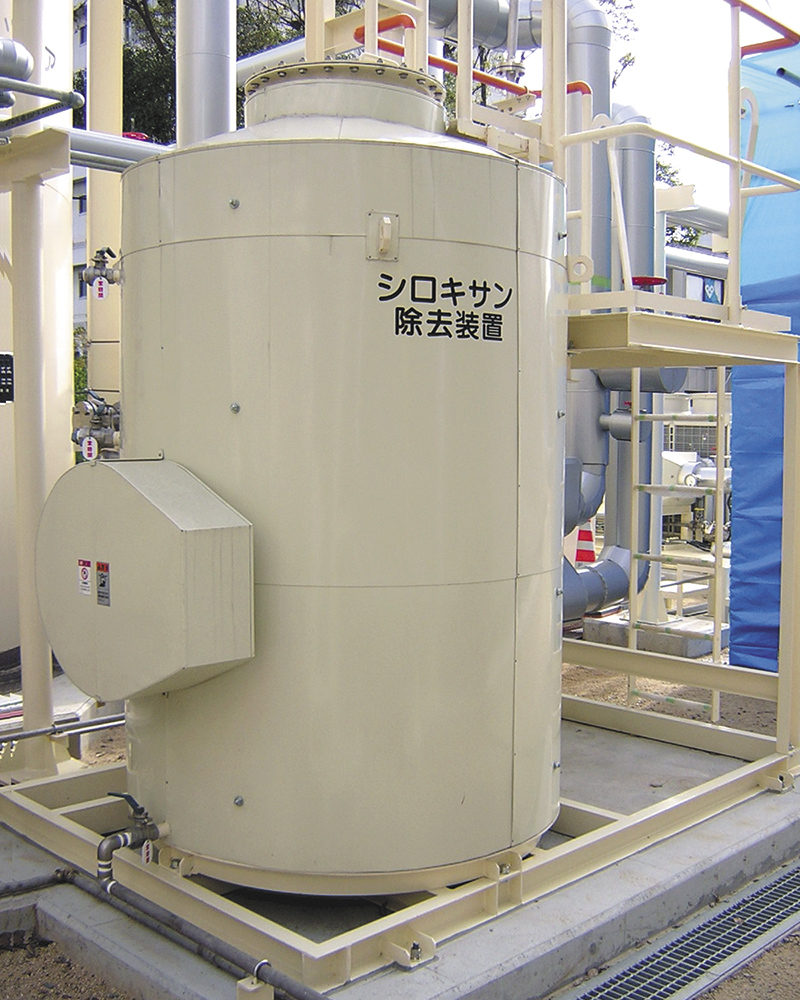

Siloxane Removal Device

Biogas

, especially digester gas derived from sewage sludge, contains siloxanes.

Siloxanes cause combustion problems in generators and must be removed.

At Miura, we use special activated carbon specifically designed to remove siloxanes.