Miura

Miura Deodorizing Device (3)

Manufacturer: Miura Chemical Equipment Co., Ltd.

Catalytic Oxidation Device

As reducing chemical substances, including VOCs (volatile organic compounds), becomes a key issue in the manufacturing industry, Miura has extensive experience and a proven track record in VOC countermeasures, earning it a high reputation and trust.

[Application]

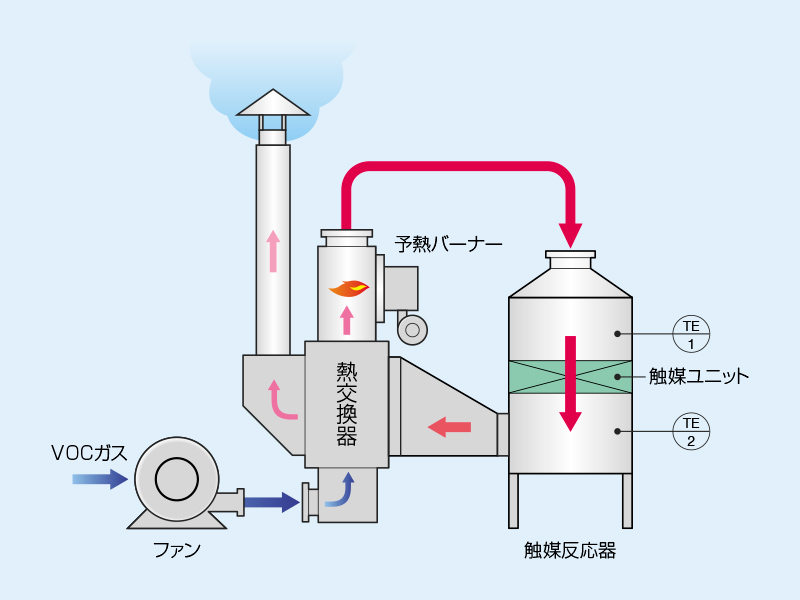

This device uses a catalyst to oxidize and decompose VOCs in exhaust gases.

Its applications include odor control and solvent treatment for gases emitted from manufacturing processes at chemical plants.

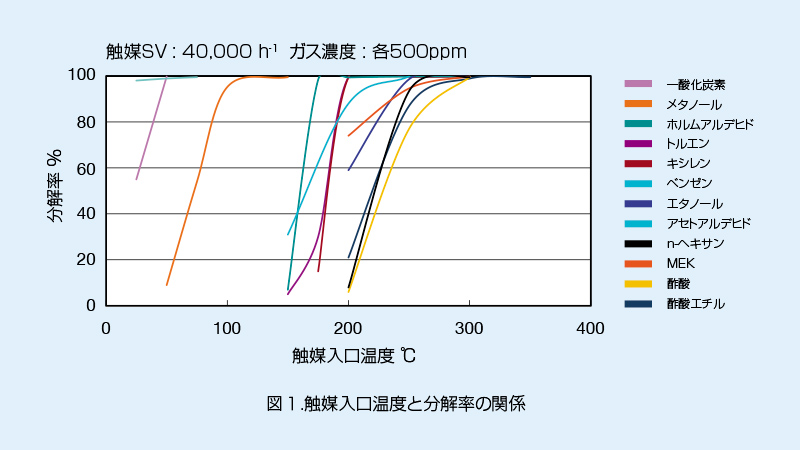

The oxidative decomposition temperature for direct combustion is 700-800°C, but using a catalyst can lower the temperature to 200-400°C.

Catalytic Oxidation Device

It consists of a heat exchanger, preheater, and catalytic reactor, and has a processing capacity of over 99%.

Processing at low temperatures is possible, reducing fuel costs.

Fuel can be selected according to customer needs, including city gas, LPG, kerosene, and electricity.

Oxidation catalyst

By using highly active precious metals, it has high processing capacity even at low temperatures.It is also possible to analyze and regenerate used catalysts.

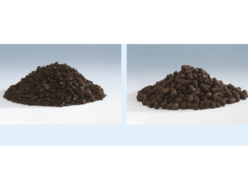

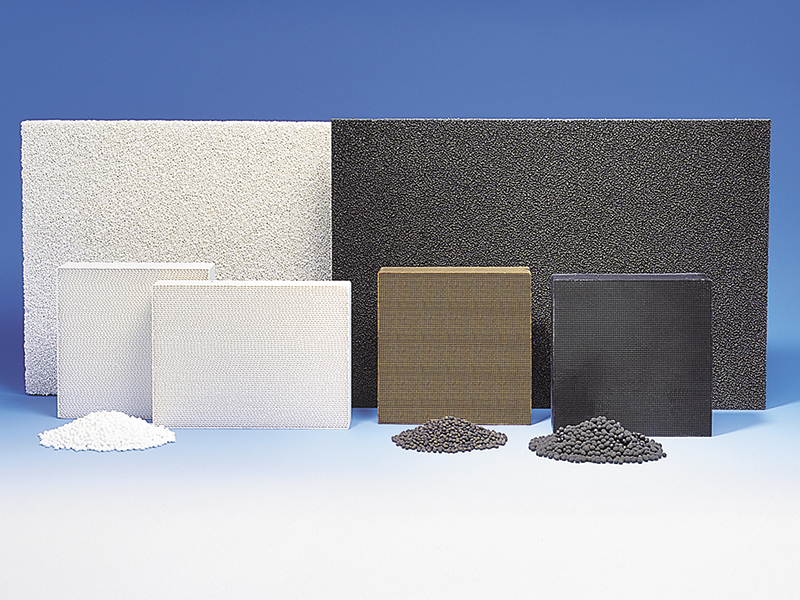

Types of oxidation catalysts

The catalyst is made by supporting precious metals containing active ingredients such as platinum and palladium on a carrier.

There are three types of catalysts available depending on their shape: foam metal, honeycomb, and granular. The optimal one can be selected based on the processing air volume, gas properties, heat, and other conditions.

Reaction Data