Miyawaki

Miyawaki AGH50 Ball Float Traps

Manufacturer: MIYAWAKI Inc.

Model: AGH50

Features

large discharge capacity

It is much larger discharge capacity among MIYAWAKI air traps.

Tailored design

Manufacturing with stainless steel

Typical applications

Suitable for air pipings, aftercoolers, receiver tanks, gas pipimgs, and other such applications.

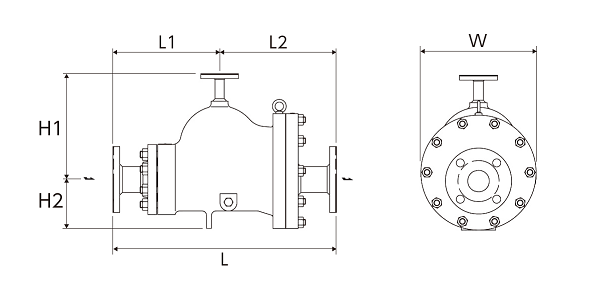

Dimensions/Weight

| Size | Flange standards | Dimensions (mm) | Dimensions (in) | Weight | ||||||||||||

| L | L1 | L2 | H1 | H2 | W | L | L1 | L2 | H1 | H2 | W | (kg) | (lb) | |||

| 2” | JIS (FF,RF) | 10K,16K,20K | 525 | 250 | 275 | 250 | 115 | 270 | 20.7 | 9.8 | 10.8 | 9.8 | 4.5 | 10.6 | 62,0 | 136.4 |

| 30K | 65,0 | 143.0 | ||||||||||||||

| 40K | ||||||||||||||||

| DIN | PN40 | 64,0 | 140.8 | |||||||||||||

| ASME/JPI (RF) | 150lb | 64,0 | 140.8 | |||||||||||||

| 300lb | ||||||||||||||||

| 600lb | 535 | 255 | 280 | 21.1 | 10.0 | 11.0 | 67,0 | 147.4 | ||||||||

| 2 1/2” | JIS (FF,RF) | 10K,16K,20K | 545 | 260 | 285 | 21.5 | 10.2 | 11.2 | 64,0 | 140.8 | ||||||

| 30K | 550 | 265 | 285 | 21.7 | 10.4 | 11.2 | 70,0 | 154.0 | ||||||||

| 40K | ||||||||||||||||

| DIN | PN40 | 66,0 | 145.2 | |||||||||||||

| ASME/JPI (RF) | 150lb | 68,0 | 149.6 | |||||||||||||

| 300lb | ||||||||||||||||

| 600lb | 560 | 270 | 290 | 22.0 | 10.6 | 11.4 | 72,0 | 158.4 | ||||||||

| 3″ | JIS (FF,RF) | 10K,16K,20K | 545 | 260 | 285 | 21.5 | 10.2 | 11.2 | 67,0 | 147.4 | ||||||

| 30K | 555 | 265 | 290 | 21.9 | 10.4 | 11.4 | 73,0 | 160.6 | ||||||||

| 40K | ||||||||||||||||

| DIN | PN40 | 69,0 | 151.8 | |||||||||||||

| ASME/JPI (RF) | 150lb | 72,0 | 158.4 | |||||||||||||

| 300lb | ||||||||||||||||

| 600lb | 565 | 270 | 295 | 22.2 | 10.6 | 11.6 | 77,0 | 169.4 | ||||||||

| 4″ | JIS (FF,RF) | 10K,16K,20K | 575 | 275 | 300 | 22.6 | 10.8 | 11.8 | 71,0 | 156.2 | ||||||

| 30K | 590 | 285 | 305 | 23.2 | 11.2 | 12.0 | 78,0 | 171.6 | ||||||||

| 40K | 83,0 | 182.6 | ||||||||||||||

| DIN | PN40 | 73,0 | 160.6 | |||||||||||||

| ASME/JPI (RF) | 150lb | 73,0 | 160.6 | |||||||||||||

| 300lb | 82,0 | 180.4 | ||||||||||||||

| 600lb | 600 | 200 | 310 | 23.6 | 7.9 | 12.2 | 96,0 | 211.2 | ||||||||

*Available flange standards: ASME/JPI, DIN, JIS

*Customized face-to-face dimensions on request.

*Please contact MIYAWAKI for further information.

Specifications

| Model | Connection | Max. operating pressure | Max. operating pressure differential | Max.operating temperature | Bodymaterial | ||||

| Type | Size | PMO(MPa) | PMO(psig) | ⊿PMX(MPa) | ⊿PMX(psig) | TMO(℃) | TMO(℉) | ||

| AGH50-5 | Flanged FF,RF | 2” | 3,2 | 464 | 0,5 | 72.5 | 400 | 752 | Cast steel SCPH2 |

| 2 1/2” | |||||||||

| 3″ | |||||||||

| 4″ | |||||||||

| AGH50-10 | 2” | 1,0 | 145 | ||||||

| 2 1/2” | |||||||||

| 3″ | |||||||||

| 4″ | |||||||||

| AGH50-20 | 2” | 2,0 | 290 | ||||||

| 2 1/2” | |||||||||

| 3″ | |||||||||

| 4″ | |||||||||

| AGH50-32 | 2” | 3,2 | 464 | ||||||

| 2 1/2” | |||||||||

| 3″ | |||||||||

| 4″ | |||||||||

*Available flange standards: ASME/JPI, DIN, JIS

*Customized face-to-face dimensions on request.

*Please contact MIYAWAKI for further information.

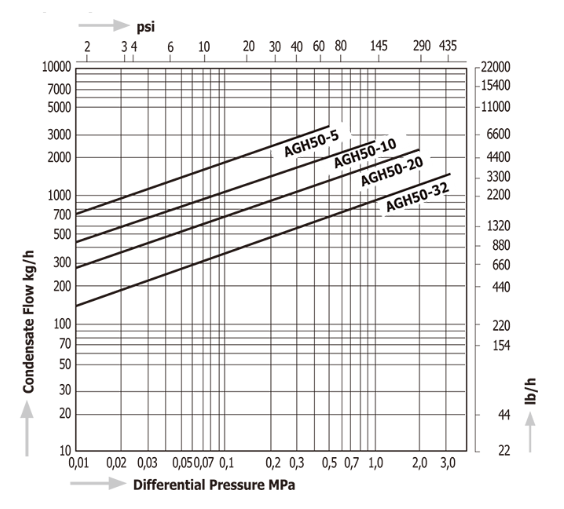

Discharge Capacity