Miyawaki

Miyawaki DX1 (for Sanitation Systems) Diaphragm Steam Traps

Manufacturer: MIYAWAKI Inc.

Model: DX1

Features

Easy attachment and detachment with a ferrule connection

Compact design

Face-to-face (height) 30mm (1.18in)

Made completely of stainless steel

DX1R with orifice to prevent condensate accumulation also available.

Can be used in a set with a check valve (CX1). (available separately)

Typical applications

Suitable for condensate discharge from sanitary piping

Suitable for condensate discharge in the SIP (Sterilization in Place) process by steam

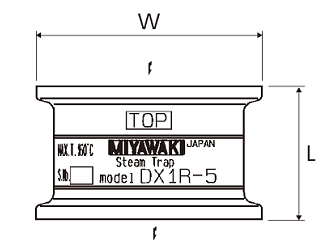

Dimensions/Weight

| Size (mm) | Size (in) | Dimensions (mm) | Dimensions (in) | Weight | |||

| L | W | L | W | (kg) | (lb) | ||

| 38 (ISO standard) | 1.5 (ISO standard) | 30 | 50,5 | 1.2 | 2.0 | 0,18 | 0.4 |

Specifications

| Model | Connection | Max. operating pressure | Max. operating pressure differential | Max. operating temperature | Valve opening temperature | Body material | ||||||

| Type | Size | Size | (MPa) | (psig) | (MPa) | (psig) | (℃) | (℉) | (℃) | (℉) | ||

| DX1-5 | Ferrule | 38mm (ISO standard) | 1.5 in (ISO standard) | 0,5 | 72.5 | 0,5 | 72.5 | 160 | 320 | 5℃ below Saturation temperature | 9℉ below Saturation temperature | Stainless steel SUS316 |

| DX1R-5* (with orifice) | ||||||||||||

*DX1R: The design (with orifice) prevents condensate from accumulating in the body in the event of a halt in the supply of steam.

Maximum allowable pressure (PMA): 1,0MPa (145psig) PMA is the pressure that can be tolerated by pressure-resistant parts (body).

Maximum allowable temperature (TMA): 185℃ (365℉) TMA is the temperature that can be tolerated by the main unit (body).

Min. operating pressure differential (⊿PMN): 0,01MPa (1.5psig) ⊿PMN is the minimum operating differential pressure between the trap inlet and outlet.

Surface height: Ra1.6a (Ra: Arithmetic average height)

*You can use this in a set with a check valve (CX1). (available separately)

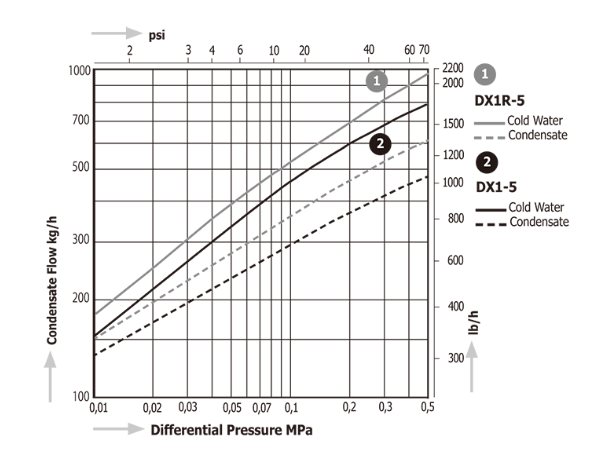

Discharge Capacity

The condensate flow rate shown assumes a condensate temperature at approximately 10℃ (18℉) below saturation temperature.