Miyawaki

Miyawaki GH70 Ball Float Steam Traps

Manufacturer: MIYAWAKI Inc.

Model: GH70

Features

Quick startup

Automatically discharges initial air and cold condensate.

Suitable for medium to high capacity steam processes

Adjust the degree of valve opening according to volume of condensate generated to provide maximized heat exchange capacity.

Condensate recovery

With its high degree of back pressure tolerance, this model supports condensate recovery.

Easy maintenance

For quick and easy maintenance, this model can be repaired directly in line.

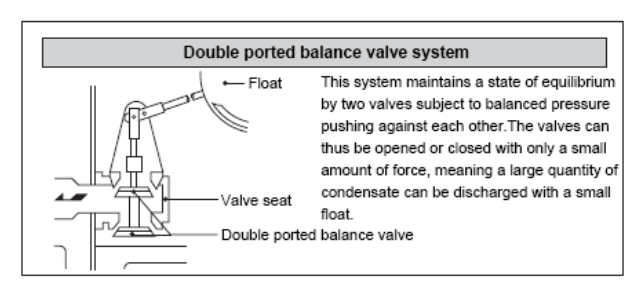

High discharge capacity

A double ported balance valve provides a large discharge capacity in comparison with single valve models.

Typical applications

Suitable for use in industrial plant systems, F&B devices, and dyeing/cleaning devices.

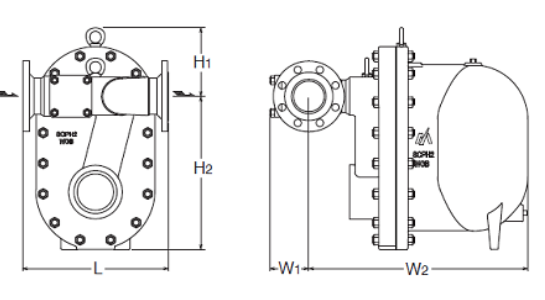

Dimensions/Weight

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||||

| L | H1 | H2 | W1 | W2 | L | H1 | H2 | W1 | W2 | (kg) | (lb) | |

| 3″ | 380 | 180 | 400 | 105 | 570 | 15.0 | 7.1 | 15.8 | 4.1 | 22.4 | 172 | 379.3 |

| 4″ | ||||||||||||

*Available flange standards: ASME/JPI 150lb, 300lb, DIN PN40, JIS 10K, 16K, 20K

*Customized face-to-face dimensions on request.

*Please contact MIYAWAKI for further information.

Specifications

| Model | Connection | Max. operating pressure | Max. operating differential pressure | Max. operating temperature | Air vent type | Body material | ||||

| Type | Size | PMO (MPa) | PMO (psig) | ⊿PMX (MPa) | ⊿PMX (psig) | TMO (℃) | TMO | |||

| GH70-21F | Flanged FF,RF* | 3″ | 2,1 | 305 | 2,1 | 305 | 400 | 752 | Bimetal | Cast steel SCPH2/WCB |

| 4″ | ||||||||||

*Available flange standards: ASME/JPI 150lb, 300lb, DIN PN40, JIS 10K, 16K, 20K

The maximum allowable pressure (PMA) reaches 4.0 MPa (580 psig), while the maximum allowable temperature (TMA) is 400°C (752°F). Additionally, the maximum operating back pressure (PMOB) is set at 90% of the inlet-side pressure.

*ASTM material (WCB) on request.

This product uses a double ported balance valve system so if the actual condensate volume is significantly lower than the product’s discharge capacity, there may be a steam leak.

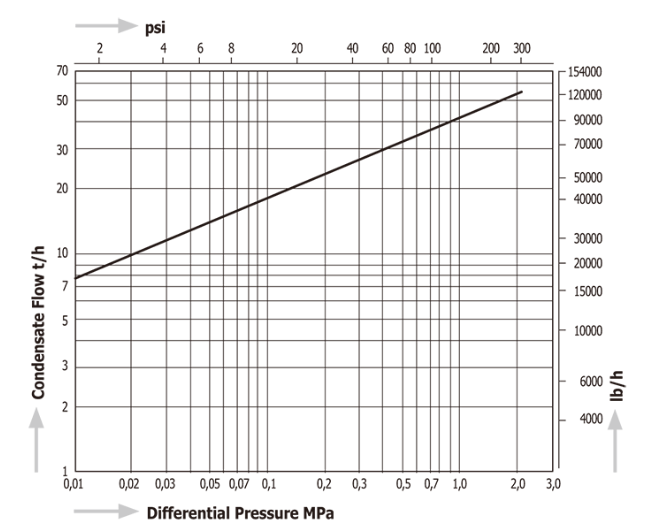

Discharge Capacity