Miyawaki

Miyawaki SU2N Thermodynamic Disc Steam Traps

Manufacturer: MIYAWAKI Inc.

Model: SU2N

Features

Flexible installation

This product can be installed either horizontally or vertically.

Superb durability

The body of the product is made from stainless steel, making it durable and corrosion-resistant, even in aggressive media.

Auto blow off and air vent

Thanks to a bimetal ring, the trap smoothly discharges initial air and cold condensate. (Auto blow-off mechanism)

Tailored design

Manufacturing with custom face-to-face dimensions is possible.

Typical applications

Suitable for high temperature and pressure steam main lines, steam tracing, and other such applications.

Dimensions/Weight

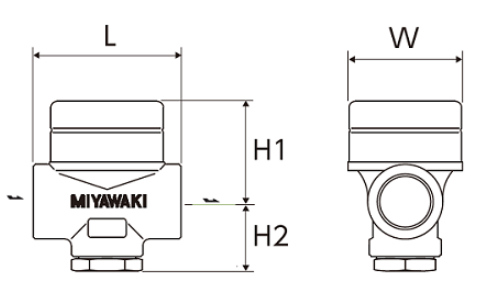

Screwed

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||

| L | H1 | H2 | W | L | H1 | H2 | W | (kg) | (lb) | |

| 1/2” | 70 | 47 | 32 | 53 | 2.8 | 1.9 | 1.3 | 2.1 | 0,8 | 1.8 |

| 3/4” | ||||||||||

| 1” | 75 | 51 | 3.0 | 2.0 | 1,0 | 2.2 | ||||

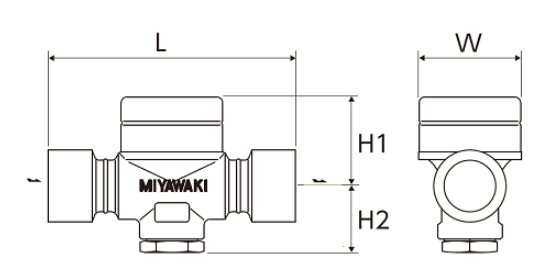

Socket Weld

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||

| L | H1 | H2 | W | L | H1 | H2 | W | (kg) | (lb) | |

| 1/2” | 140 | 47 | 32 | 53 | 5.51 | 1.85 | 1.26 | 2.09 | 1,5 | 3.3 |

| 3/4” | 1,4 | 3.1 | ||||||||

| 1” | 1,3 | 2.9 | ||||||||

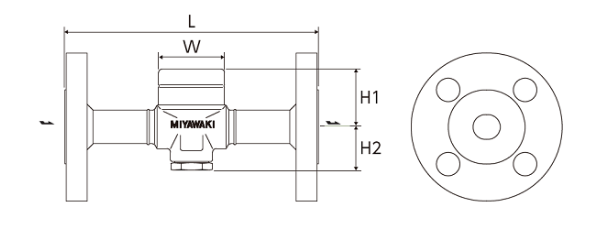

Flanged

JIS,ASME

| Size | Dimensions (mm) | Dimensions (in) | Weight (kg) | Weight (lb) | ||||||||||||||||

| L | H1 | H2 | W | L | H1 | H2 | W | JIS(FF,RF) | ASME/JPI(RF) | JIS(FF,RF) | ASME/JPI(RF) | |||||||||

| 10K,16K,20K | 30K | 40K | 150lb | 300lb | 600lb | 10K,16K,20K | 30K | 40K | 150lb | 300lb | 600lb | |||||||||

| 1/2” | 205 | 47 | 32 | 53 | 8.1 | 1.9 | 1.3 | 2.1 | 2,6 | 3,8 | 4,1 | 2,2 | 2,7 | 3,3 | 5.7 | 8.4 | 9.0 | 4.9 | 6.0 | 7.3 |

| 3/4” | 3,0 | 4,1 | 4,4 | 2,6 | 3,7 | 4,6 | 6.6 | 9.0 | 9.7 | 5.7 | 8.2 | 10.1 | ||||||||

| 1” | 4,0 | 5,0 | 5,4 | 3,0 | 4,3 | 5,4 | 8.8 | 11.0 | 11.9 | 6.6 | 9.5 | 11.9 | ||||||||

DIN PN40

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||

| L | H1 | H2 | W | L | H1 | H2 | W | (kg) | (lb) | |

| DN15 | 150 | 47 | 32 | 53 | 5.9 | 1.9 | 1.3 | 2.1 | 2,6 | 5.7 |

| DN20 | 3,3 | 7.3 | ||||||||

| DN25 | 160 | 6.3 | 3,8 | 8.4 | ||||||

*Customized face-to-face dimensions on request.

*Please contact MIYAWAKI for further information.

Specifications

| Model | Connection | Max. operating pressure | Max. operating pressure differential | Max. operating temperature | Body material | ||||

| Type | Size | PMO (MPa) | PMO (psig) | (MPa) | (psig) | TMO (℃) | TMO (℉) | ||

SU2N | Screwed | 1/2” | 4,6 | 667 | 4,6 | 667 | 425 | 800 | Stainless steel SUS 420J2 |

| 3/4” | |||||||||

| 1” | |||||||||

| SU2NF | Flanged FF,RF | 1/2” | |||||||

| 3/4” | |||||||||

| 1” | |||||||||

| SU2NW | Socket Weld SW | 1/2” | |||||||

| 3/4” | |||||||||

| 1” | |||||||||

SU2NF flange and pipe are carbon steel

SU2NW welded parts are carbon steel

Maximum allowable pressure (PMA): 6,4MPa (928psig) (SU2N). PMA is the pressure that can be tolerated by pressure-resistant parts (body).

Maximum allowable temperature (TMA): 425℃ (800℉). TMA is the temperature that can be tolerated by pressure-resistant parts (body).

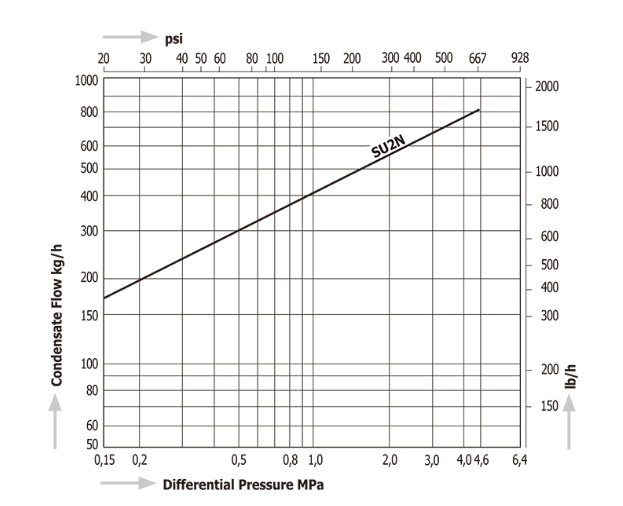

Discharge Capacity