Miyawaki TB1N Temperature Control Steam Trap

Manufacturer: MIYAWAKI Inc.

Model: TB1N

Features

This product can be installed for use either horizontally or vertically.

Compact design

Can be installed in small spaces.

Uses a highly sensitive disc bimetal

Precise operation in response to even slight temperature changes. The trap’s light weight also means it only places a slight load on the copper or other pipe to which it is connected.

Stable tracing

MIYAWAKI’s own original valve mechanism suppresses fluctuations in trace temperature and reduces temperature unevenness.

Simple maintenance

Maintenance is simple thanks to bimetals being grouped into units.

Typical applications

Suitable for steam tracing and instruments in the fields of oil, petroleum chemistry, electricity, iron manufacturing, and other such fields.

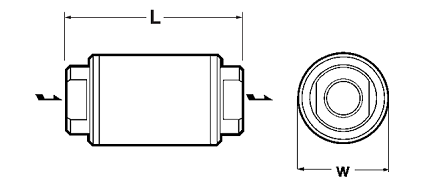

Dimensions/Weight

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||

| L | W | L | W | (kg) | (lb) | |

| 1/4” | 70 | 38 | 2.8 | 1.5 | 0,35 | 0.8 |

Specifications

| Model | Connection | Max. operating pressure | Max. operating differential pressure | Max. operating temperature | Adjustable range | Standard set temperature | Body material | ||||||

| Type | Size | PMO (MPa) | PMO (psig) | (MPa) | (psig) | TMO (℃) | TMO (℉) | (℃) | (℉) | (℃) | (℉) | ||

| TB1N | Screwed Rc,NPT | 1/4” | 1,6 | 232 | 1,6 | 232 | 350 | 662 | 50 – 90 | 122 – 194 | 70 (at 0,5MPa) | 158 (at 73psig) | Carbon steel S25C |

| 3/8” | |||||||||||||

*It is possible to change the standard factory set temperature. Please specify the operating pressure and set temperature.

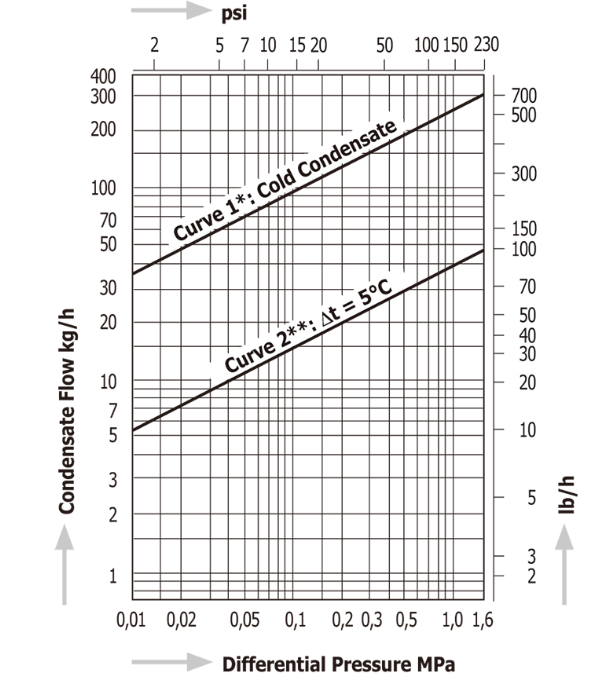

Discharge Capacity

⊿t is the difference between the temperature of a temperature control trap when the valve is initially opened and condensate temperature. The temperature difference (⊿t) upon the initial passage of air is great, and indicates that the flow rate will also increase.

* Curve1 shows the trap’s maximum capacity when discharaging cold condensate.

**Curve2 shows the trap’s maximum capacity when discharaging hot condensate at a temperature of 5°C (9°F) below the adjusted temperature of the trap.

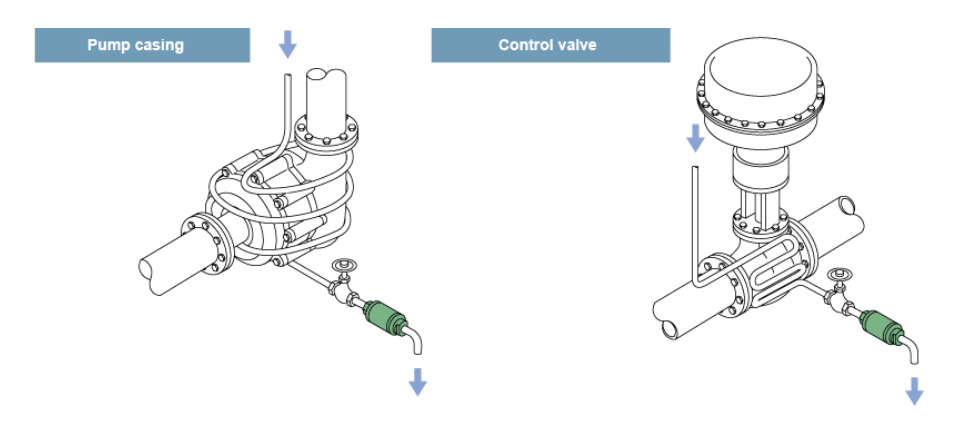

Installation Examples