Japan, Nabtesco

Nabtesco Welfare Equipment

Made in Japan

Manufacturer: Nabtesco Corporation

Toward Normalization in Society

Prosthetic knee joints greatly impact the independence, mobility, and social participation of people who have lost their legs. With a shortage of caregivers, welfare equipment helps individuals become independent. To support active participation in society, “normalization” is essential.

Nabtesco developed the world’s first microprocessor-controlled intelligent prosthetic knee joint. The microprocessor detects walking speed, adjusts the pneumatic cylinder, and controls the knee joint’s swing speed for comfortable, natural walking.

Nabtesco became the first in the world to develop a microprocessor-controlled intelligent prosthetic knee joint as mobility support equipment. The microprocessor detects the user’s walking speed, adjusts the pneumatic cylinder, and automatically controls the swing speed of the knee joint to help the person walk comfortably and naturally.

Social Value Provided by the Business

Our technology that supports prosthetic knee joint users in going out and walking helps to reduce burden on them, thereby contributing to increasing their social participation.

We contribute to normalization.

Main Products

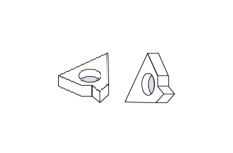

This is the world’s first knee joint made by combining a hydraulic electronic control system with a four-link mechanism. Its sensor and microprocessor instantly check the situation for automatic control of the hydraulic cylinder, which functions to change the swing speed of the knee joint according to the walking speed of the user and to prevent sudden falls.

Wheel Unit for Rollators with a Speed Control Braking System

The world’s first wheel unit for rollators has a built-in automatic braking system that functions when the speed of the rollator exceeds a certain limit, thereby ensuring its safety. This unit enables even those with concerns about rollators due to the risk of excess speed and falls to go out with rollators safely and with peace of mind.