Nachi

Nachi AG Power Drills

Manufacturer: Nachi-fujikoshi corp

Model:AG

Features

Highly rigid form and large pocket

Enlarged the point of edge

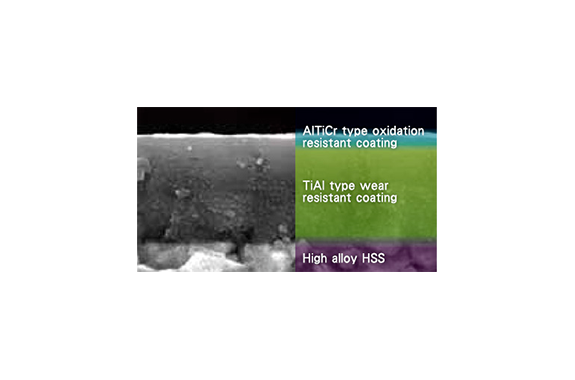

AG Coating

Cross section structure of AG coating

Smooth coating

Work Material

| Code No. | Carbon Steels S45C S50C | Alloy Steels SCM NAK | Hardened Steels Mold Steels | Hardened Steels 50~65HRC | Stainless Steels | Titanium Alloys Nickel Alloys SUS420 | Cast Irons FCD/FC | ||

|---|---|---|---|---|---|---|---|---|---|

| 25~40HRC | 40~50HRC | SUS304 SUS316 | SUS420 | ||||||

| AGPSD | ◎ | ◎ | ◎ | × | × | ○ | ○ | ○ | ◎ |

| AGPLSD | ◎ | ◎ | ◎ | × | × | ○ | ◎ | ||

| AGPLSD | ◎ | ◎ | ◎ | × | × | ○ | ◎ | ||

◎: Excellent ○: Good ×: Not Used No mark: Not Recommended

Performance

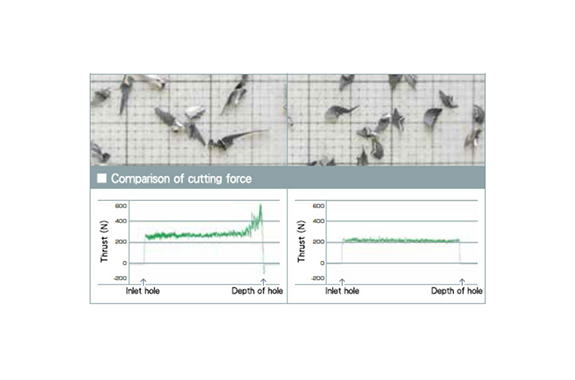

AGPSD AG Power Drills

Cutting Force

Tool: AGPSD3.0

Cutting Speed: 30 m/min

Rotation: 3,180 min⁻¹

Feed Speed: 330 mm/min

Feed: 0.1 mm/rev (Non-step)

Hole Depth: 15 mm Blind Hole

Work Material: S50C (180HB)

Cutting Fluid: Wet

Machine: Vertical machining center

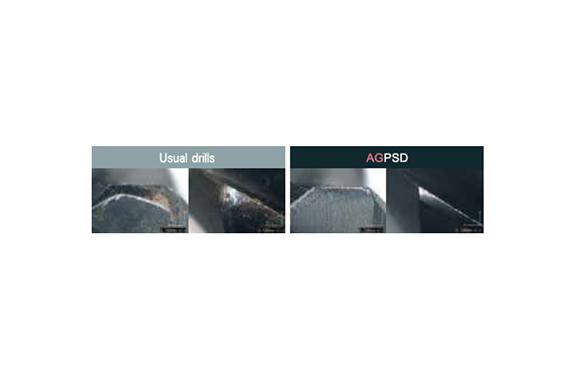

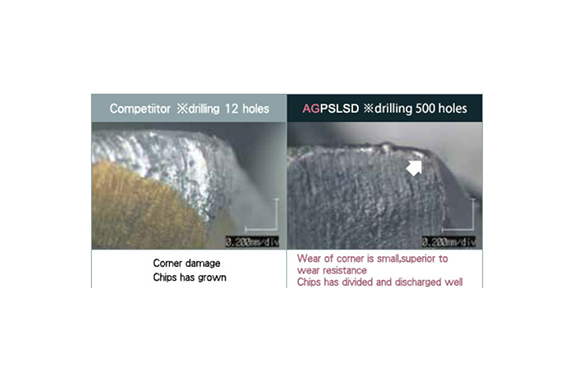

Wear comparison after 204 holes drilling Comparison of non-step drilling of tempered alloy steel

Comparison of non-step drilling of tempered alloy steel

Tool: AGPSD6.0

Cutting Speed: 24 m/min

Rotation: 1,272 min⁻¹

Feed Speed: 230 mm/min

Feed: 0.18 mm/rev (Non-step)

Hole Depth: 30 mm Blind Hole

Work Material: SCM440 (32 HRC)

Cutting Fluid: Wet

|Machine: Vertical machining center

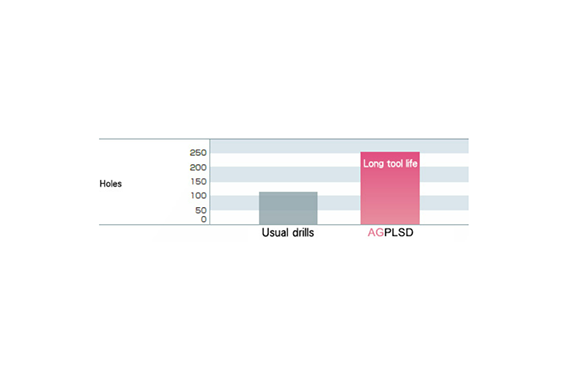

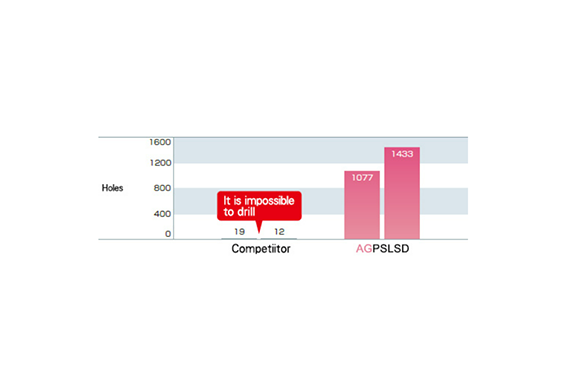

AGPSLSD AG Power Semi-long Drills

Comparison of tool life

Tool: AGPLSD3.0

Cutting Speed: 24 m/min

Rotation: 2,500 min⁻¹

Feed Speed: 200 mm/min

Feed: 0.08 mm/rev (Non-step)

Hole Depth: 21 mm (7D) Blind Hole

Work Material: S50C (180HB)

Cutting Fluid: Wet

Machine: Vertical machining center

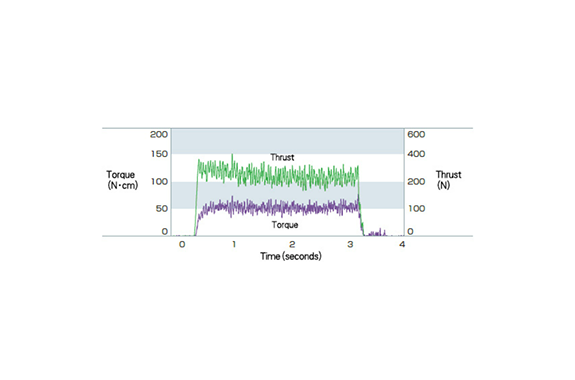

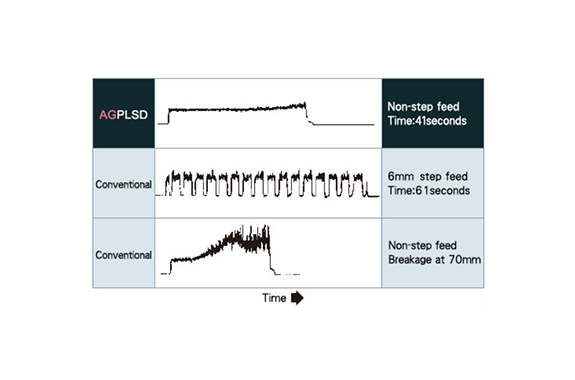

AGPLSD AG Power Long Drills

AGPLSD AG Power Long Drills

Comparison of cutting force and time Tool: AGPLSD6.0

Tool: AGPLSD6.0

Cutting Speed: 18 m/min

Rotation: 955 min⁻¹

Feed Speed: 143 mm/min

Feed: 0.15 mm/rev

Hole Depth: 102 mm Blind Hole

Work Material: Carbon Steels (260HB)

Cutting Fluid: Wet

Machine: Vertical machining center

Comparison of tool life