Nachi

Nachi AQUA EX FLAT Drill

Manufacturer: Nachi-fujikoshi corp

Model: AQUA EX FLAT

Outline

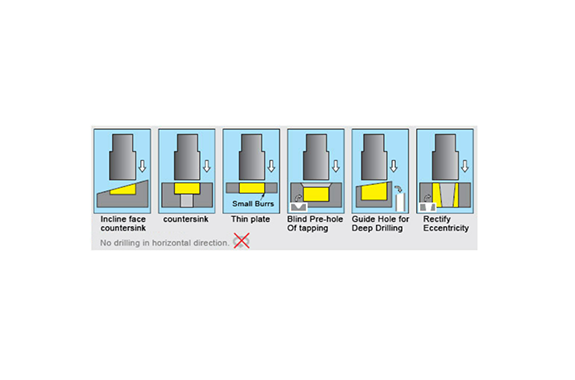

Drill for counter boring has great performance.

Spot facing machining capability for a wide range of applications such as spot facing on slope. correction of eccentric holes. and thin plate machining.

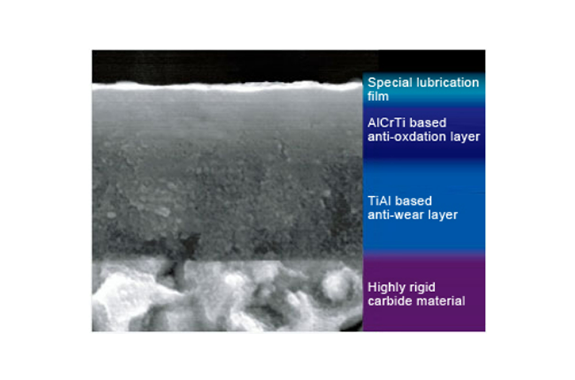

Aqua EX Coating

Better heat and wear resistance from Aqua EX coating for a super long life.

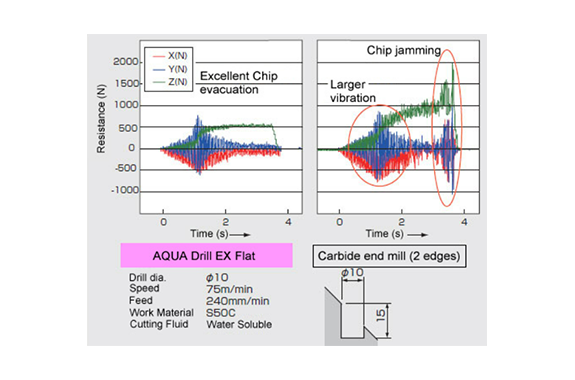

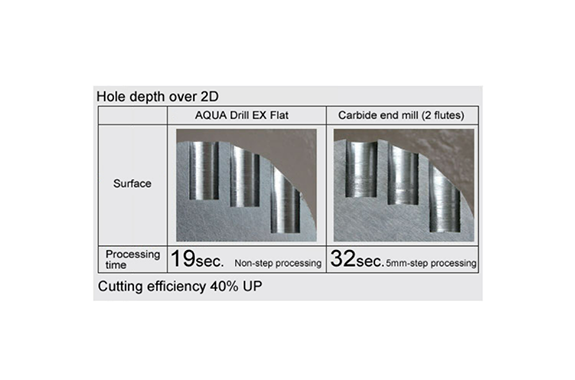

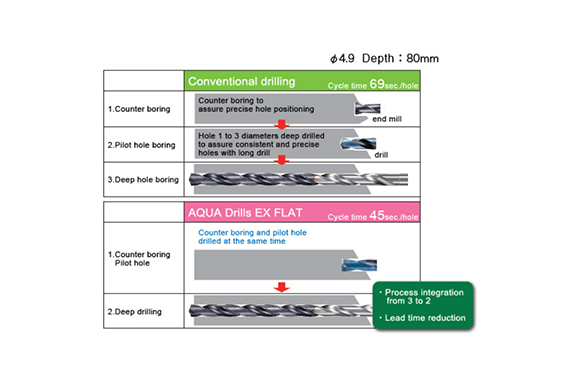

Drilling efficiency improvement due to reduced processing time

Counter boring and guide hole drilled at the same time.

Effective screw length is assured when drilling set screw holes in thin material. without increasing work.

Features

Performance opens up extensive applications

Structural Steels | Carbon Steels | Hardened Steels Alloy Steels | Hardened Steels Mold Steels | Hardened Steels | Stainless Steels | Titanium Alloys / Nickel Alloys | Cast Irons | Aluminum Alloys | Copper Alloys |

| SS400 | S45C S50C | SGr NAK | 25 to 40HRC | 40 to 50HRC | SUS304 SUS316 | SUS420 | — | FCD/FC | AC/ADC |

| ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

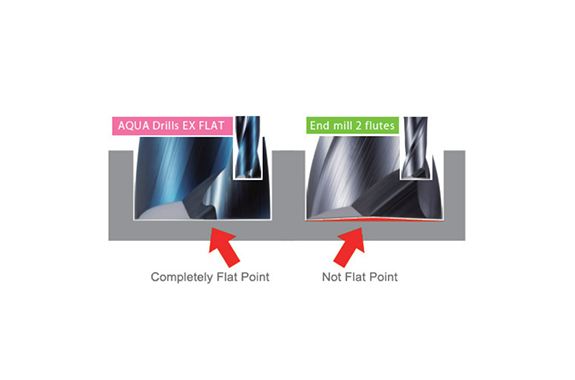

Cutting resistance on 45° angled surface Absolutely flat drill face

Absolutely flat drill face AQUA EX Coating

AQUA EX Coating

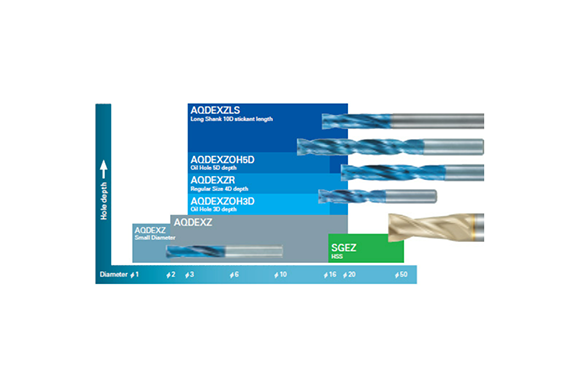

Improved resistance to oxidation. heat and wear AQUA Drill EX Flat lineup

AQUA Drill EX Flat lineup

Performance

Multi-functional flat drill

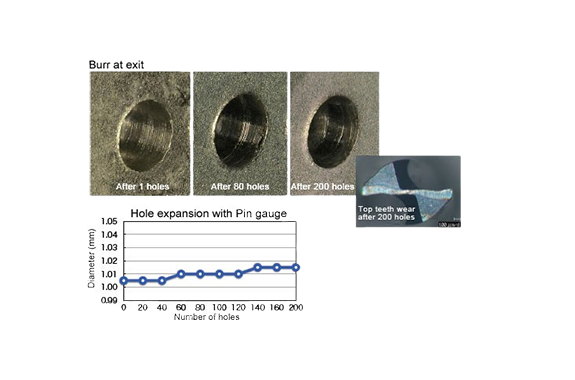

Tool: AQDEXZ0100

Diameter: ⌀1.0 mm

Speed: 30 m/min

Feed: 40 mm/min (0.005 mm/rev)

Depth: 2 mm Through

Material: SUS304

Flat Surface:

Fluid: Emulsion

Smaller burrs at exit and oversized holes

High-efficiency One shot drilling with no point holes Cutting condition on inclined hole drilling

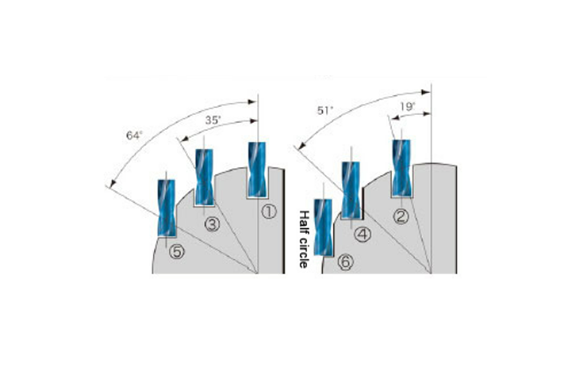

Cutting condition on inclined hole drilling

| Position No. | Angle | Speed | Feed | ||||

|---|---|---|---|---|---|---|---|

| m/min | min⁻¹ | % | mm/min | mm/rev | % | ||

| ① | 0 | 75 | 2400 | 100% | 420 | 0.18 | 100% |

| ② | 19° | 75 | 2400 | 50% | 210 | 0.09 | 50% |

| ③ | 35° | 52 | 1650 | 40% | 120 | 0.07 | 40% |

| ④ | 51° | 52 | 1650 | 70% | 120 | 0.07 | 40% |

| ⑤ | 64° | 52 | 1650 | 30% | 90 | 0.06 | 33% |

| ⑥ | Half circle | 52 | 1650 | 20% | 60 | 0.04 | 20% |

AQDEXZ1000 (⌀10)

AQDEXZ1000 (⌀10)

Work Material: S45C

Hole Depth: 15mm

Water soluble

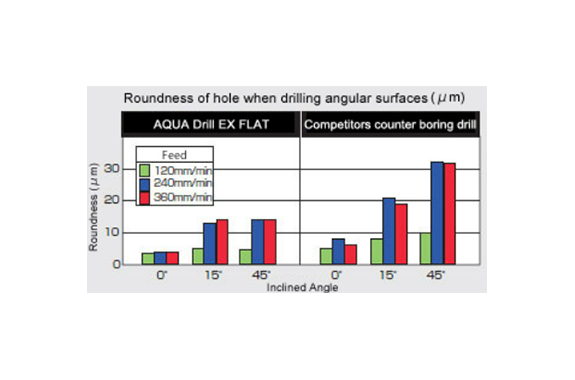

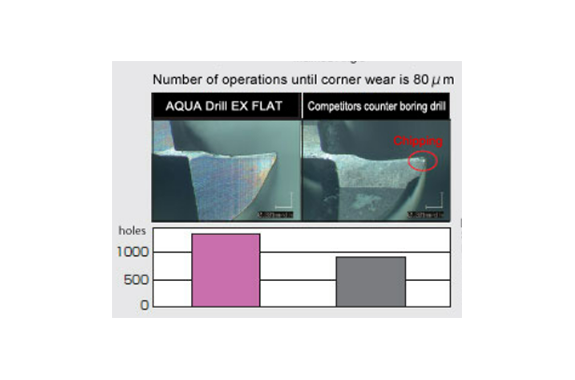

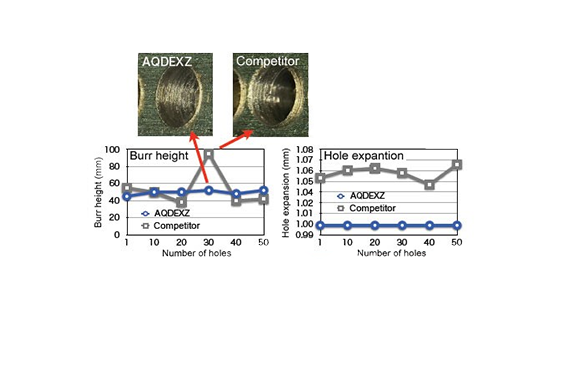

Comparison with competitors counter boring drill Drill dia. ⌀10

Drill dia. ⌀10

Speed 75 m/min

Feed 120 mm/min 1/n

240 mm/min 1/n

360 mm/min 1/n

Work Material S50C

Cutting Fluid Water Soluble

Depth 10 mm Drill dia. ⌀3

Drill dia. ⌀3

Speed 75 m/min

Feed 240 mm/min

Work Material SCM415

Cutting Fluid Water Soluble

Depth 3 mm

Slope 30°

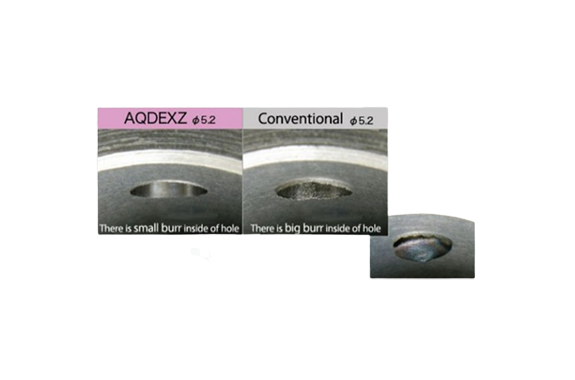

Burr size comparisor at exit of hole inside pipe materials

Speed : 75 m/min

Speed : 75 m/min

Feed : 0.09 mm/rev

Material : S45C

Outer diameter : 40 mm

Inner diameter : 30 mm

Burr height : less than 1/3

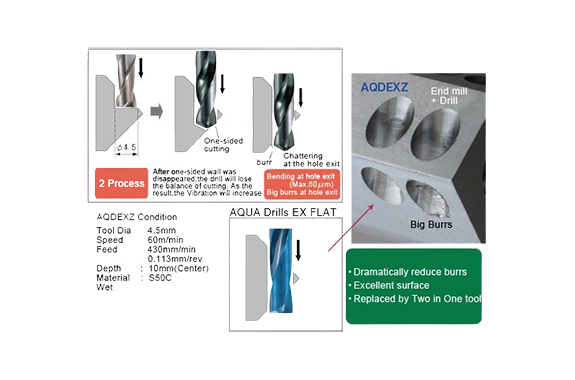

Drilling process comparison in guide holes Fuel pump parts drilling on the sloped surface

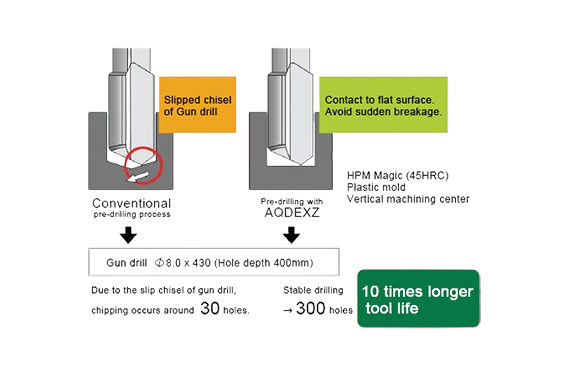

Fuel pump parts drilling on the sloped surface Gun Drill tool life extension with AQDEXZ as pre-drilling tool

Gun Drill tool life extension with AQDEXZ as pre-drilling tool

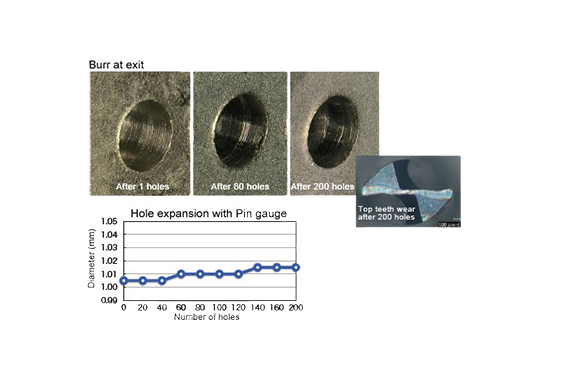

Example for stainless steels (SUS304) Tool : AQDEXZ0100

Tool : AQDEXZ0100

Dia : ⌀1.0

Speed : 30 m/min

Feed : 40 mm/min (0.005 mm/rev)

Depth : 2 mm Through

Material : SUS304

Flat Surface : 0°

Fluid : Emulsion

Top teeth wear after 200 holes

Smaller burrs at exit and oversized holes

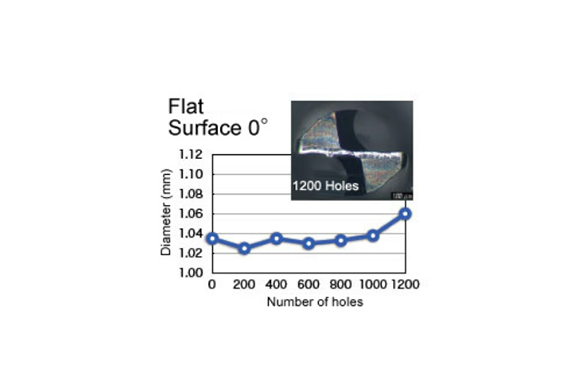

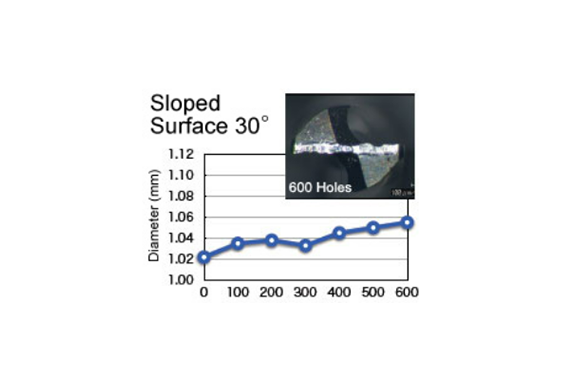

Expansion of the hole diameter for S50C

Tool : ⌀1.0

Speed : 75 m/min

Feed : 420 mm/min (0.018 mm/rev)

Depth : 2 mm blind hole

Material : S50C

Coolant : Wet

Continuous drilling 1200 holes is possible,

Equivalent tool life to conventional carbide drills. Tool : ⌀1.0

Tool : ⌀1.0

Speed : 52.5 m/min

Feed : 126 mm/min (0.008 mm/rev)

Depth : 2 mm blind hole

Material : S50C

Coolant : Wet

Continuous drilling 600 holes is possible on 30° inclined surface.

Hole accurocy of drilling thin plates of aluminum alloy (A5052)

Aqua EX Flat drill is effective for burr control.

Hole expansion within 0~5 μm.