Nachi

Nachi DuAl EX/VX Hob Gear Cutters

Manufacturer: Nachi-fujikoshi corp

Model: DuAl EX/VX Hob

Features

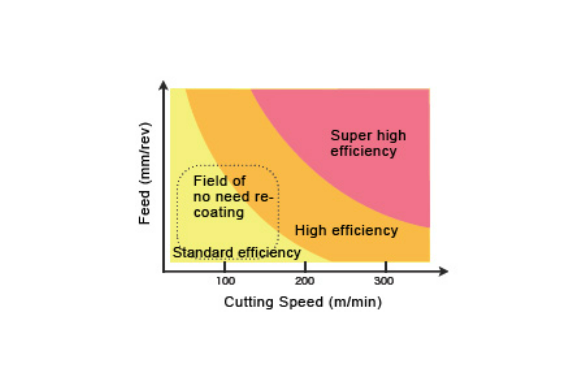

Coating selection chart of wear

| Type | Wet Hobbing (Oil, Emulsion) | Dry Hobbing | |||

|---|---|---|---|---|---|

| Standard Efficiency | High Efficiency | Super High Efficiency | High Efficiency | Super High Efficiency | |

| Re-grinding + Re-coating (Full coating) | Hyper DuAl GP | Hyper DuAl GP | Hyper Dual SP | ||

| Without re-coating (No coating on cutting face) | DuAl VX | DuAl EX | |||

Comparison chart of Hob coating

| Property | DuAl VX | DuAl EX | Hyper DuAl GP | Hyper DuAl SP |

|---|---|---|---|---|

| Wear resistance | ◯ | ◎ | ◎ | ◎ |

| Toughness | ◯ | ◯ | ◎ | ◯ |

| Heat resistance | △ | ◯ | ◎ | ◎ |

| Stability | ◎ | ◎ | ◎ | ◎ |

| Coolant | Wet & Dry | Wet & Dry | Efficient Wet & Dry | Super-efficient Dry |

| Hardness of coating | 2300 ~ 2500 | 2300 ~ 2500 | 2400 ~ 2600 | 2500 ~ 2700 |

| Heat resistance temp. | 850°C | 950°C | 1100°C | 1150°C |

Specialized coating for hobs with improved coating properties. Ideal selection of coating to suit the wear condition.

Performance

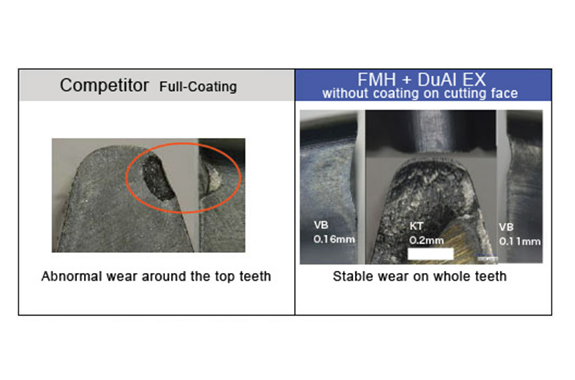

Reduction in running cost – DuAl EX Hob

Dry Hobbing without coating on cutting face.

Work spec.: m2.45 × NT54 × HA35° RH SCr420H

Hob: Ø95 × NT12 × 3TH DuAl EX Coating

Conditions: V = 180 m/min f = 3.0 mm/rev Dry Hobbing

Distance: 150 m

Reduction in running cost by stabilization

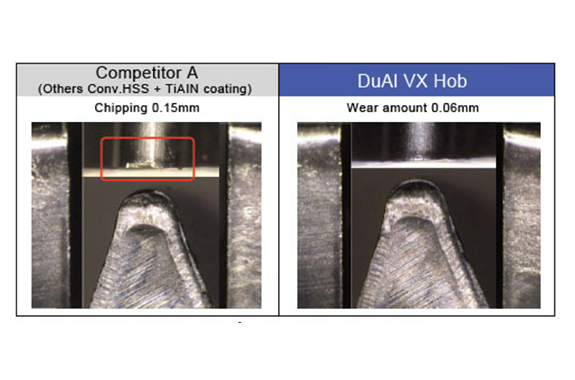

Wet Hobbing without coating on cutting face – DuAl VX Hob

Work spec.: m2.3 × NT47 × HA21° LH S53C 250~300HB

Hob spec.: Ø80 × NT12 × 3TH

Condition: V = 70 m/min f = 1.5 mm/rev

Climb Hobbing, Oil Coolant Wet Hobbing, Cutting length 150 m

It is possible to operate stable hobbing without chipping even wet condition.