Nachi

Nachi GSX MILL VL Carbide End Mills

Manufacturer: Nachi-fujikoshi corp

Model: GSX MILL VL

Outline

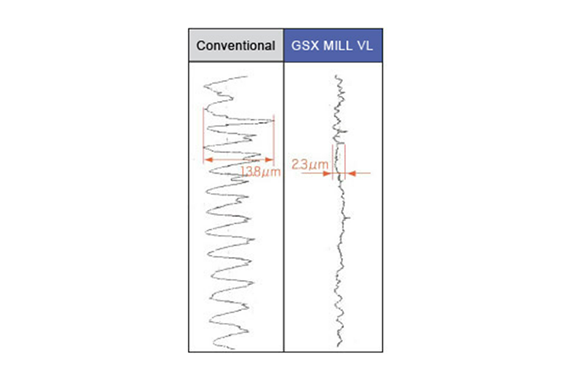

Endmill with unequal tooth spacing and variable leads to suppress chattering

It specializes for Titanium alloy and for Carbon steels and the series is made.

GSX II coating for greater heat and wear resistance. plus anti-adhesion properties.

| Code | Structural Steels | Carbon Steels | Pre-Hardened Steels Alloy Steels | Hardened Steels Mold Steels | Hardened Steels | Stainless Steels | Titanium Alloys Nickel Alloys | Cast Irons | ||

|---|---|---|---|---|---|---|---|---|---|---|

| SS400 | S45C S50C | SGr NAK | 25 to 40HRC | 40 to 50HRC | 50 to 65HRC | SUS304 SUS316 | SUS420 | — | FCD/FC | |

| GSXVL4 | ○ | ◎ | ◎ | ◎ | × | ◎ | ◎ | ◎ | — | ◎ |

| GSXVL4T | ◎ | ◎ | ||||||||

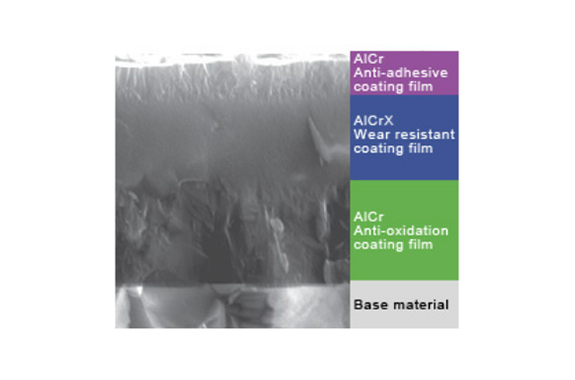

GSX II coating

With the multi-layer of heat resistance coating and hard coating. GSX MILL VL supports cutting of hardened materials. With high wear resistance and anti-adhesion properties. stable chip removal is realized for a wide range of work materials.

Features

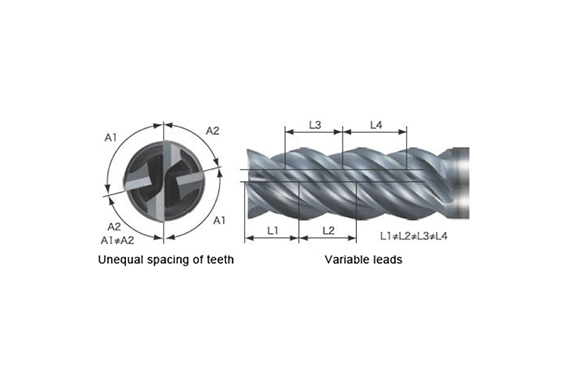

Unequal spacing of teeth.

Variable leads

Reduce vibration and realize high quality milling by adapting unequal index and lead design.

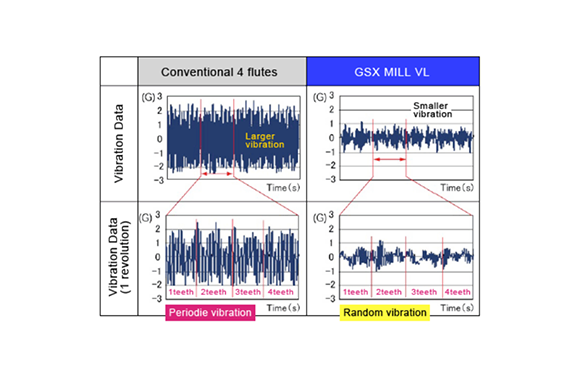

Comparison of vibration

Applicable to wide range of materials by two series Applicable to wide range of materials by two series

Applicable to wide range of materials by two series

| Applicable materials | For Steel | For Ti and Stainless |

|---|---|---|

| Carbon Steels Pre-Hardened Steels Alloy Steels Die Steels | Stainless Steels Titanium Alloys Inconel718, etc | |

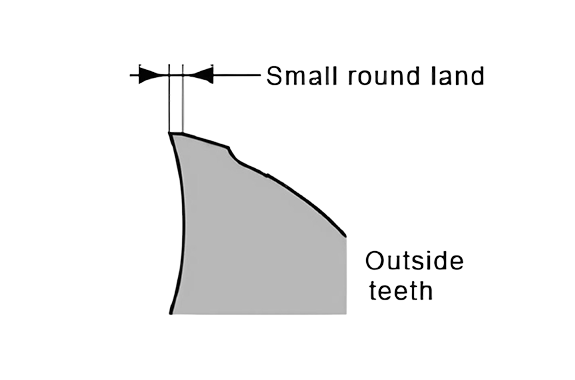

| Feature | Apply Specially designed Cutting Edge to get good surface finish Better surface finish  | Apply suitable carbide material for difficult to machine material Higher helix angle for better removability. |

GSX-II Coating

Excellent heat resistance

Achieve high heat Resistance with Al-rich composition. Multi layer structure

Multi layer structure

High hardness of coating in according to multi layer structure with AlCr and AlCrX.

Crystal structure

Great wear and resistance with optimum crystal structure.

Evaluation of oxidation resistance

Status of coating films after keeping with 1.100°C in the air after 1 hour

GSX MILL VL Series

| Geometry | FL | 2.5D | 4D | 5D (over hang length) |

For Steel | Square | GSXVL4-2.5D φ3~20 | GSXVL4-4D φ3~20 | |

| Radius | GSXVL4-R-2.5D φ6~20 | GSXVL4-R-4D φ6~20 | ||

| Multi Flutes | GSXVL6-2.5D φ6~20 | |||

| Long Shank | GSXVLLS4-1.5D φ3~20 | |||

For Ti・SUS | Square | GSXVL4T-2.5D φ3~20 | GSXVL4T-4D φ3~20 | |

| Radius | GSXVL4T-R-2.5D φ6~20 | GSXVL4T-R-4D φ6~20 | ||

| Multi Flutes | GSXVL6T-2.5D φ6~20 | |||

| Long Shank | GSXVLLS4T-1.5D φ3~20 |

Performance

GSX MILL VL Anti-Vibration Effect

Tool: Ø10

Speed: 130 m/min

Feed: 1,460 mm/min

0.09 mm/tooth

Depth of cut: ap = 10 mm, ae = 2 mm

Material: S50C

No-chatter

Higher quality surface finish

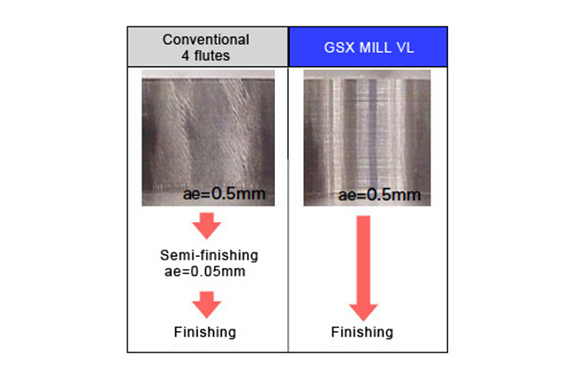

Comparison of surface roughness

Tool: Ø10

Tool: Ø10

Speed: 188 m/min

Feed: 4,000 mm/min (0.167 mm/tooth)

Depth of cut: ap = 20 mm, ae = 2 mm

Material: S50C

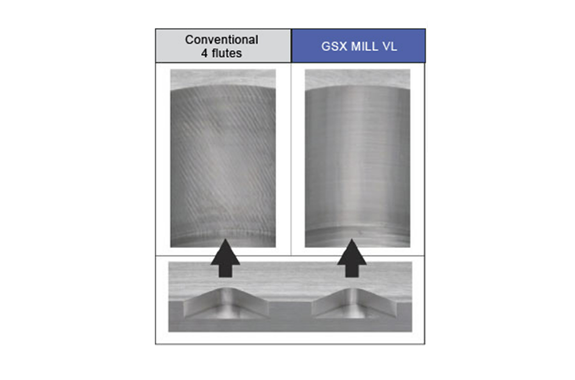

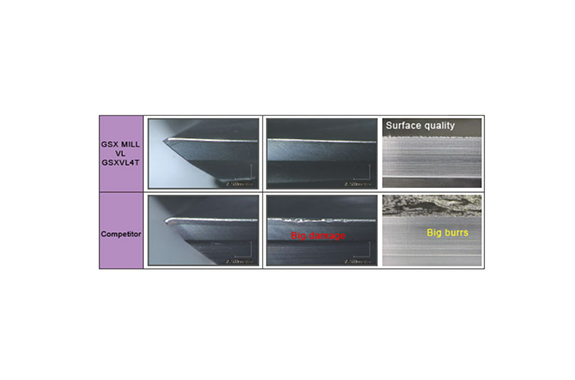

Surface roughness comparison of milling on Titanium alloys

Tool: Ø10

Speed: 188 m/min

Feed: 4,000 mm/min (0.167 mm/tooth)

Depth of cut: ap = 20 mm, ae = 2 mm

Material: S50C

Wear comparison after 140m milling of stainless steels (SUS304)

Tool: Ø10

Speed: 100 m/min

Feed: 770 mm/min

Material: SUS304

Cutting Fluid: Wet

Milling Length: 140 m

The wear of GSXVL4T is very small and normal.

Possible to keep milling.

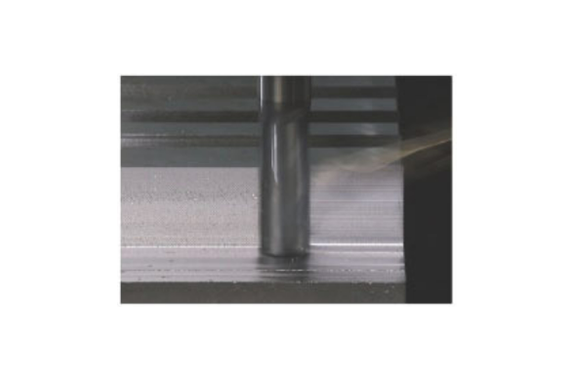

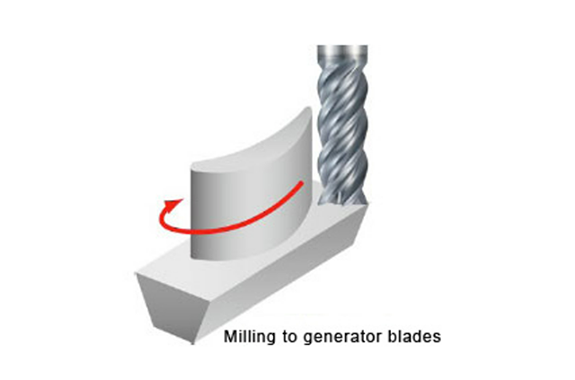

Application example of pocket thin-wall milling of Titanium Alloys

| Milling operation | Cutting Speed | Feed Speed | Depth of cut |

|---|---|---|---|

| Inner surface of the pocket Rough | Vc 90m/min | Vf 680mm/min fz 0.06mm/t On corner Vf 460mm/min fz 0.04mm/t | ap 10mm ae 0.7mm |

| Finish Vc 120m/min | Vf 900mm/min fz 0.06mm/t On corner Vf 600mm/min fz 0.04mm/t | ap 10mm ae 0.1mm | |

| Outer surface of the pocket Rough | Vc 90m/min | Vf 690mm/min fz 0.06mm/t | ap 10mm ae 0.7mm |

| Finish Vc 120m/min | Vf 1000mm/min fz 0.086mm/t | ap 10mm ae 0.1mm |

Tool: GSXVL4T-2.5D

Tool: GSXVL4T-2.5D

Ø10 × 25 × 70 × Ø10

Material: Ti6Al4V

Fluid: Water Soluble

High speed milling of thin wall.

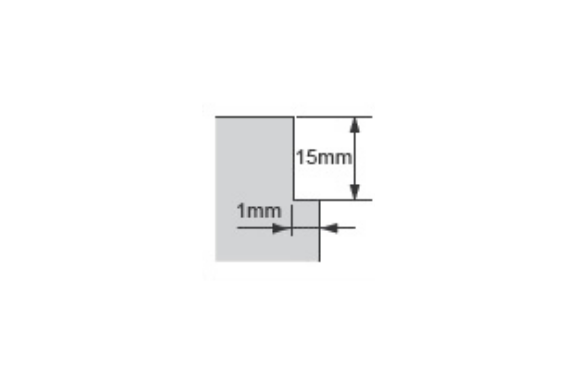

Reduction Process in SUS410J

Tool: Ø12mm Radius R2mm (4 flutes)

Milling Condition

Speed: V94 m/min (N 2,500 min⁻¹)

Feed: 500 mm/min (0.05 mm/tooth)

Depth of cut: ap = 28

Material: SUS410J

Coolant: Wet