Nachi

Nachi GTE Series Thread Grinding Machines

Manufacturer: Nachi-fujikoshi corp

Model: GTE Series

Outline

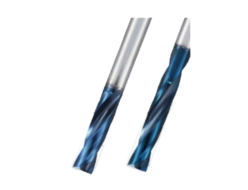

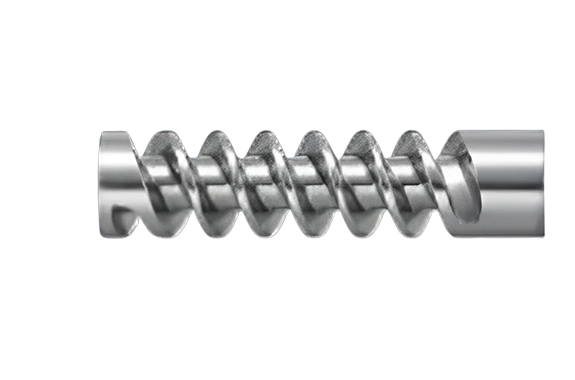

NACHI’s Thread Grinding Machine Supports Wide Range of Machining Products from Ball Screws to Auto Parts

High versatility and excellent accuracy GTE-7A

Workpieces, the machine handles diameters from Ø4 to 200mm with high versatility and excellent accuracy.

Precision ball screws smaller than Ø12mm is also applicable.

Space saving: 45% smaller than the GTE-10A.

Thread grinding machines for mass production “GTE-SA series”

Thread grinding machines for mass production “GTE-SA series”Thread grinding machine for mass production of automotive and other parts.

Each automation such as automatic clamping. automatic groove alignment. and automatic swivel wheel head helps to achieve high productivity.

Two space-saving models are available in different size. Max. 200mm and Max. 400mm (distance between enters).

Features

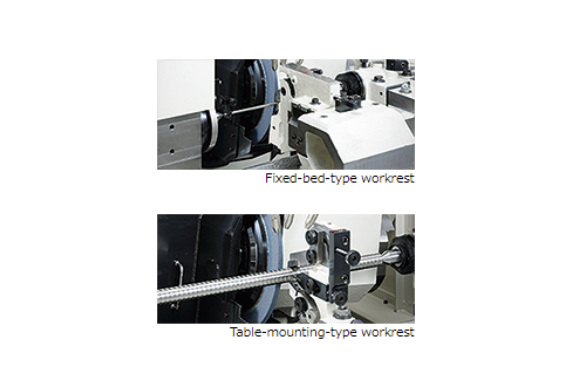

Workrest is compatible with a wide range of workpieces

Fixed-bed-type workrest which supports changeover is best for smalldiameter workpieces.

Fixed-bed-type workrest supports Ø12mm and smaller diameters.

Changeover to thin-type regular workrest is also possible.

One unit can grind a wide range of workpieces by using fixed-bed-type workrest for small diameter ball screws. and table-mounting-type workrest for medium and large ballscrews. The built-in motor greatly expands the angle domain of the swivel wheel head.

The built-in motor greatly expands the angle domain of the swivel wheel head.

Drum-type swivel wheel head and built-in low-vibration spindle.

The drum-type swivel wheel head provides high-accuracy grinding and simultaneously swivels the grinding wheel and dresser ±45°. The wheel spindle uses a built-in motor.

Improved maintainability and eco-friendly machine.

Improved maintainability and eco-friendly machine.

We eliminated drive belts and adopted grease lubrication for the wheel spindle. This reduces air consumption volume by 50%.

Specification

Thread grinding machines “GTE Series”

| GTE-7A | GTE-10A | GTE-20A | |

|---|---|---|---|

| Max. center distance (mm) | 800 | 1,500 | 2,300 |

| Max. grinding outside diameter (mm) | 200 | 200 | 200 |

| Grinding lead (mm) | 700 | 1,300 | 2,100 |

| Grinding wheel size (OD×W×ID) (mm) | 355×(10~32)×152.4 | 510×(10~75)×228.6 | 510×(10~75)×228.6 |

| Wheel spindle swivel angle (°) | ±45 | ±45 | ±45 |

| Max. table stroke (mm) | 700 | 1,400 | 2,200 |

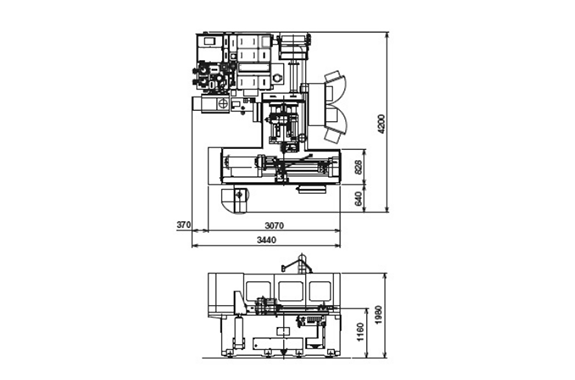

| Floor space (Wmm×Dmm) | 3,440 × 4,200 | 6,500 × 4,200 | 7,110 × 4,200 |

| Weight (kg) | 10,000 | 12,000 | 18,000 |

| GTE-30A | GTE-40A | GTE-50A | |

|---|---|---|---|

| Max. center distance (mm) | 3,650 | 4,500 | 5,400 |

| Max. grinding outside diameter (mm) | 200 | 200 | 200 |

| Grinding lead (mm) | 3,300 | 4,000 | 5,000 |

| Grinding wheel size (OD×W×ID) (mm) | 510×(10~75)×228.6 | 510×(10~75)×228.6 | 510×(10~75)×228.6 |

| Wheel spindle swivel angle (°) | ±45 | ±45 | ±45 |

| Max. table stroke (mm) | 3,400 | 4,100 | 5,100 |

| Floor space (Wmm×Dmm) | 10,000 × 4,200 | 12,200 × 4,200 | 13,900 × 4,200 |

| Weight (kg) | 24,000 | 25,000 | 26,000 |

Thread grinding machines for mass production “GTE-SA series”

| GTE-5SA2 | GTE-5SA4 | |

|---|---|---|

| Max. center distance (mm) | 200 | 400 |

| Max. grinding outside diameter (mm) | 250 | 250 |

| Grinding lead (mm) | 150 | 350 |

| Grinding wheel size (OD×W×ID) (mm) | 405×(10~32)×152.4 | 405×(10~32)×152.4 |

| Wheel spindle swivel angle (°) | ±30 | ±30 |

| Max. table stroke (mm) | 200 | 400 |

| Floor space (Wmm×Dmm) | 2,000 × 2,800 | 2,400 × 2,800 |

| Weight (kg) | 6,500 | 7,500 |

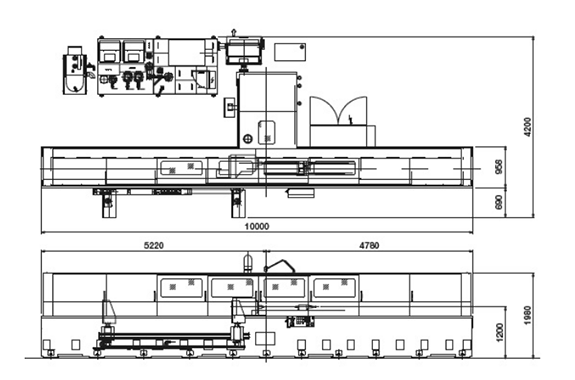

Layout diagram

GTE-7A GTE-30A

GTE-30A This machine is considered a strategic resource (or service) according to restrictions in the foreign exchange and trade laws. Based on these laws. export from Japan requires an export permit from the Japanese government.

This machine is considered a strategic resource (or service) according to restrictions in the foreign exchange and trade laws. Based on these laws. export from Japan requires an export permit from the Japanese government.