Nachi

Nachi LP Series Palletizing Robots

Manufacturer: NACHI

Model: LP Series: LP130/180/210-01

Features

High-speed palletizing

1,500 packages per hour for 130kg loads (LP130)

1,800 packages per hour for 60kg loads (LP130)

Flexible system setup is available with 130kg, 180kg, or 210kg capacity models.

Handle a variety of loads

Easily lift different shapes and sizes.

Optional palletizing hands available to carry loads that are small or large.

Compact layout

Compact design reduces interference within a large operating range so work area layouts can be flexible and compact.

Easy operation

Teaching operations are easy for novices to understand.

Interactive instructions are possible.

Automatic program generator.

Controller

FD11

Paradise function enabling easy operation

Equipped with an automatic program generation function that can be used simply by inputting work measurements and selecting a palletizing pattern.

Also offers special functions such as an “overlapping placement prevention” function and a “work height correction” function that supports bags for which thickness changes according to self-weight. These functions realize simple setting and teaching.

By using the simulation software FDonDesk. it is possible to create programs and to check palletizing conditions and cycle time on a PC.

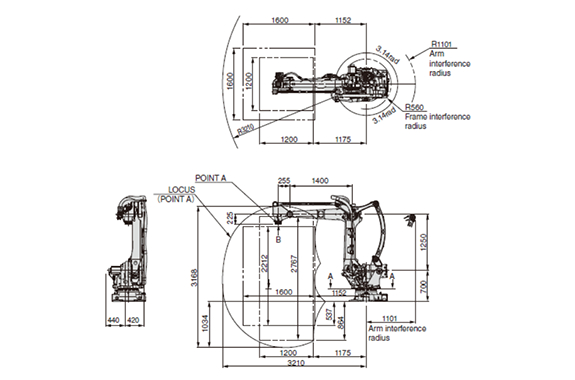

Operating range

The specifications are subject to changes without notice.

In case that an end user uses this product for military purpose or production of weapon. this product may be liable for the subject of export restriction stipulated in the Foreign Exchange and Foreign Trade Law. Please go through careful investigation and necessary formalities for export.

Specification

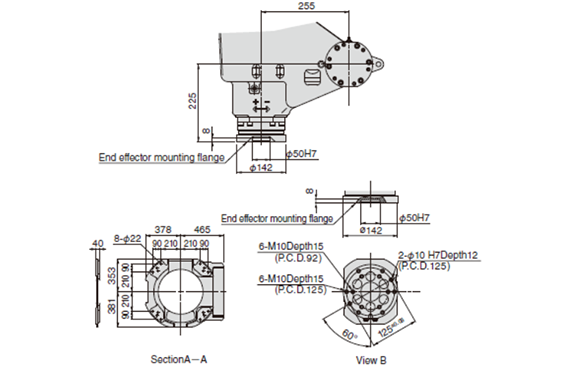

| Specification | LP130-01 | LP180-01 | LP210-01 |

|---|---|---|---|

| Construction | Articulated construction | Articulated construction | Articulated construction |

| Number of axes | 4 | 4 | 4 |

| Drive system | AC servo system | AC servo system | AC servo system |

| Max. operating area | |||

| Joint J1 | ±3.14rad | ±3.14rad | ±3.14rad |

| Joint J2 | +0.71 to -1.65rad | +0.71 to -1.65rad | +0.71 to -1.65rad |

| Joint J3 | +0.30 to -2.04rad | +0.30 to -2.04rad | +0.30 to -2.04rad |

| Joint J4 | ±6.28rad | ±6.28rad | ±6.28rad |

| Max. velocity | |||

| Joint J1 | 2.27rad/s | 2.01rad/s | 1.83rad/s |

| Joint J2 | 2.01rad/s | 1.75rad/s | 1.75rad/s |

| Joint J3 | 2.01rad/s | 1.83rad/s | 1.75rad/s |

| Joint J4 | 6.98rad/s | 6.28rad/s | 5.24rad/s |

| Max. Payload | |||

| Wrist | 130kg | 180kg | 210kg |

| Forearm | 25kg | 25kg | 25kg |

| Max. allowable moment of inertia | |||

| Joint J4 | 50kgm² | 69kgm² | 100kgm² |

| Repeatability | ±0.09mm | ±0.09mm | ±0.09mm |

| Air piping | -101.3 to 690kPa | -101.3 to 690kPa | -101.3 to 690kPa |

| Operating pressure | 2-φ12×8 (up to wrist) | 2-φ12×8 (up to wrist) | 2-φ12×8 (up to wrist) |

| Signal line for applications | 20 circuits (up to wrist) | 20 circuits (up to wrist) | 20 circuits (up to wrist) |

| Installation method | Floor mounted | Floor mounted | Floor mounted |

| Installation conditions | Ambient temperature: 0 to 45°C | Ambient temperature: 0 to 45°C | Ambient temperature: 0 to 45°C |

| Ambient humidity: 20 to 85% RH | Ambient humidity: 20 to 85% RH | Ambient humidity: 20 to 85% RH | |

| Vibration: ≤ 0.5G | Vibration: ≤ 0.5G | Vibration: ≤ 0.5G | |

| Robot mass | 1,150kg | 1,150kg | 1,150kg |

1[rad]=180/[], 1[Nm]=1/9.8[kgfm]

Varies according to wrist load conditions and installation position.

JIS B 8432 compliant.