Nachi

Nachi SG FLAT Drills

Manufacturer: Nachi-fujikoshi corp

Model: SG FLAT

Outline

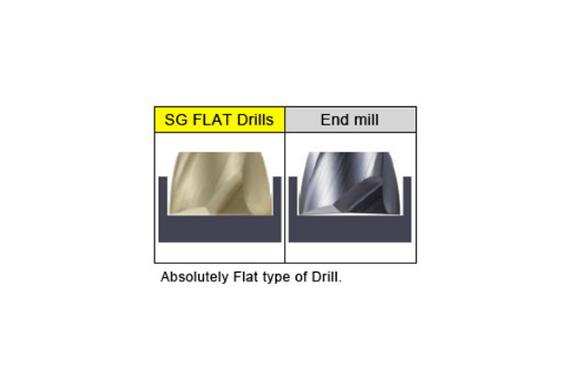

Flat drills made of HSS superior in cost performance

Realize stable drilling of larger flat-bottom holes with the adoption of high alloy HSS(FMX) and SG coating.

Size range : Ø16 to Ø50

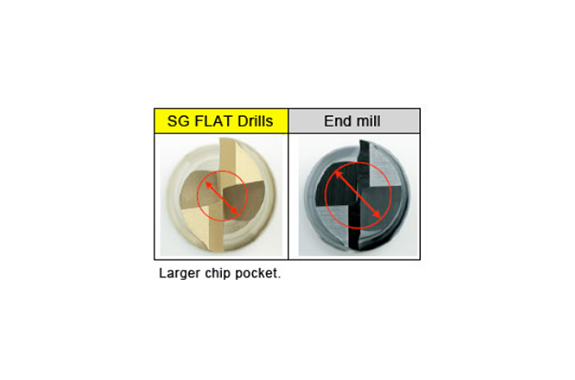

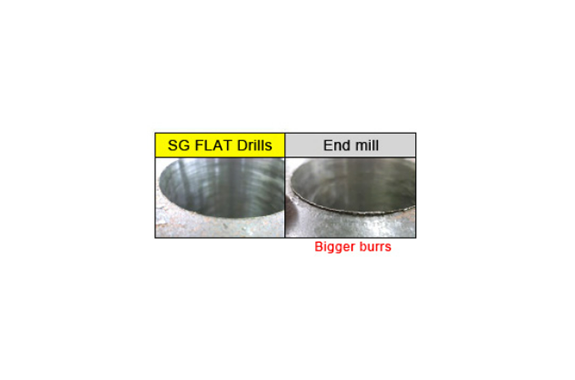

Well balance between rigidity and chip evacuation with the adoption of optimal flute geometry

Restrain hole expansion and realize the drilling of high accurate flat-bottom holes.

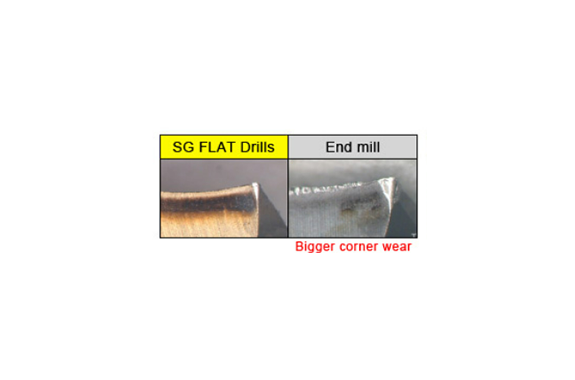

Adoption of Gash land

Improve chipping resistance on the corner of cutting edge and realize longer tool life.

Features

Multi-Function Drills

Applicable work materials

| Structural Steels | Carbon Steels | Hardened Steels Alloy Steels | Hardened Steels Mold Steels | Hardened Steels | Stainless Steels | Titanium Alloys Nickel Alloys | Cast Irons | Aluminum Alloys | Copper Alloys | ||

| SS400 | S45C S50C | SGr NAK | 25 to 40HRC | 40 to 50HRC | 50 to 65HRC | SUS304 | SUS316 | – | FCD/FC | AC/ADC | Cu |

| ◎ | ◎ | ◎ | ◎ | × | × | ○ | ○ | ○ | ○ | ○ | ○ |

Cutting edge geometry of SG FLAT Drills

Performance

Perfoemance of SG FLAT Drills Tool Diameter: ⌀20

Tool Diameter: ⌀20

Cutting Speed: 25 m/min

Feed: 80 mm/min (0.2 mm/rev)

Hole Depth: 20 mm Blind

Material: S50C

Coolant: Wet Tool Diameter: ⌀50 mm

Tool Diameter: ⌀50 mm

Cutting Speed: 25 m/min

Feed: 80 mm/min (0.2 mm/rev)

Hole Depth: 20 mm Through

Material: S50C

Coolant: Wet

Example : Counterboring without pilot hole (Ø50)

Tool Diameter: ⌀20 mm

Cutting Speed: 25 m/min

Feed: 45 mm/min (0.28 mm/rev)

Hole Depth: 30 mm blind hole (5 mm step)

Material: S50C

Coolant: Wet

Machine: Vertical BT50

Chip jams are likely to occur

High cutting resistance

Example : Counterboring a bolt hole (M30)

Tool Diameter: ⌀50 mm

Cutting Speed: 25 m/min

Feed: 45 mm/min (0.28 mm/rev)

Hole Depth: 30 mm blind hole (5 mm step)

Material: S50C

Coolant: Wet

Machine: Vertical BT50

Attention to chip length!