Nachi

Nachi SG Series Drills

Manufacturer: Nachi-fujikoshi corp

Model: SG Series: SG-ESR/ESS

Outline

Longest service life for high-speed steel (HSS) drills

Powder HSS with SG Coating and the tool life is 2-3 times of conventional drills.

Stable and high precision drilling

Extremely precise positioning and Stable drilled hole diameter.

Stable drilling is realized for a wide range of work materials

The SG-ESR drill realizes stable machining for a wide range of work materials with improved chip breaking and chip removal.

The SG-ESS drill newly supports even smaller diameters (Ø0.5 to Ø1) that expands applications.

Features

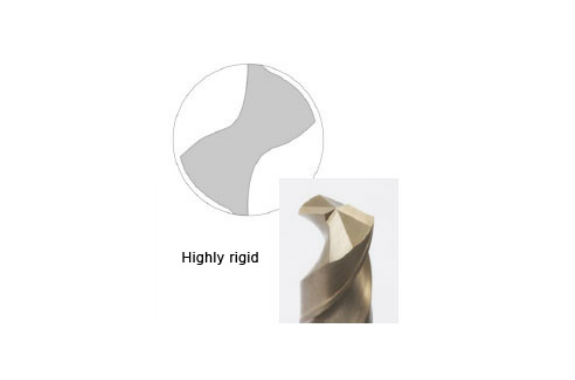

Flute Geometry of SG-ESR

SG-ESR Drills From carbon steel, alloy steel to SUS304

From carbon steel, alloy steel to SUS304

SG-ESS Drills

Suitable for high hardness materials such as:

Pre-hardened steels

Heat-treated steels

Enables good chip curl and separation

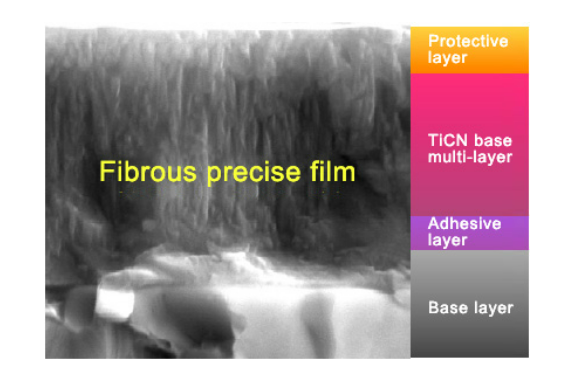

SG Coating

Specialized Film for Drill with Fine Structure

Fine and multiple layer structure improve rigidity and wear-resistance

Fibrous precise films can control fatigue crack propagation and prevent the big damage to coating film

Performance

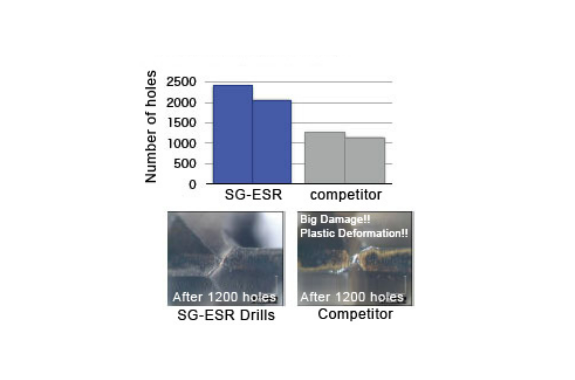

Drilling of S50C SCM440 SGESR

Tool: 6.8 mm

Cutting Speed: 40 m/min

Feed: 330 mm/min (0.18 mm/rev)

Work Material: S50C (180HB)

Hole Depth: 20 mm Through Hole

Coolant: Water-soluble

Tool: 6.8 mm

Cutting Speed: 20 m/min

Feed: 115 mm/min (0.12 mm/rev)

Work Material: SC440 (32HRC)

Hole Depth: 20 mm Through Hole

Coolant: Water-soluble

Drilling of Stainless steels (SUS304) SGESR

Tool: 6.8 mm

Cutting Speed: 12 m/min

Feed: 77 mm/min (0.14 mm/rev)

Work Material: SUS304

Hole Depth: 20 mm Through Hole

Coolant: Water-soluble

Compare the difference of chip separation

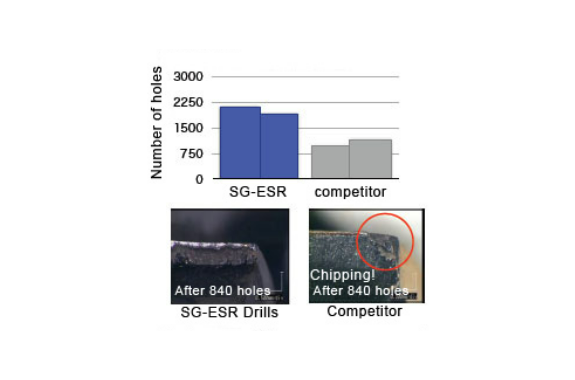

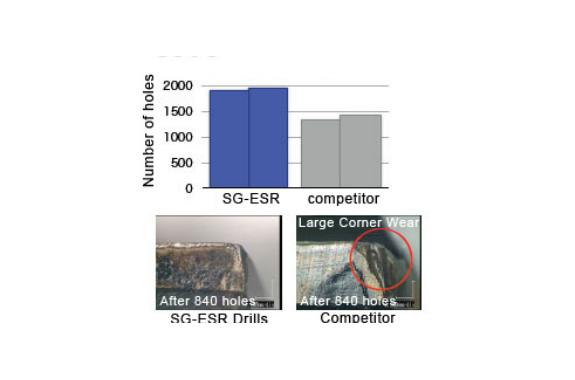

Tool life (SS400 SUS304)

SS400

Tool: 6 mm

Cutting Speed: 40 m/min

Feed: 400 mm/min (0.19 mm/rev)

Work Material: SS400

Hole Depth: 19 mm

Coolant: Emulsion

SUS304

Tool: 12 mm

Cutting Speed: 12 m/min

Feed: 80 mm/min (0.25 mm/rev)

Work Material: SUS304

Hole Depth: 28 mm

Coolant: Emulsion

S50C

Tool: 6 mm

Cutting Speed: Vc 40 m/min (2100 min⁻¹)

Feed: 420 mm/min (0.2 mm/rev)

Work Material: S50C (180HB)

Hole Depth: 19 mm Through Hole

Coolant: Emulsion

SCM440H (32HRC)

Tool: 2 mm

Cutting Speed: Vc 28 m/min (4450 min⁻¹)

Feed: 400 mm/min (0.09 mm/rev)

Work Material: SC440 (32 HRC)

Hole Depth: 6 mm Blind Hole

Coolant: Emulsion

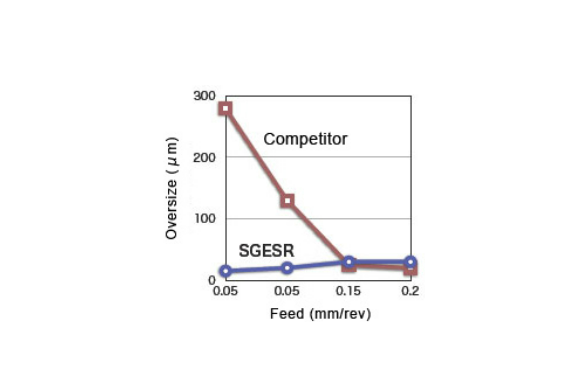

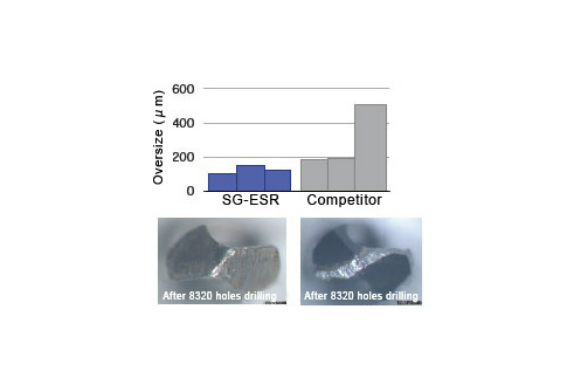

Oversize – Comparison in each feed rate

Tool: ⌀6 mm

Cutting Speed: Vc 40 m/min

Work Material: S50C (180HB)

Hole Depth: 19 mm Through Hole

Coolant: Emulsion

Max Oversize: 30 μm (SGESR)

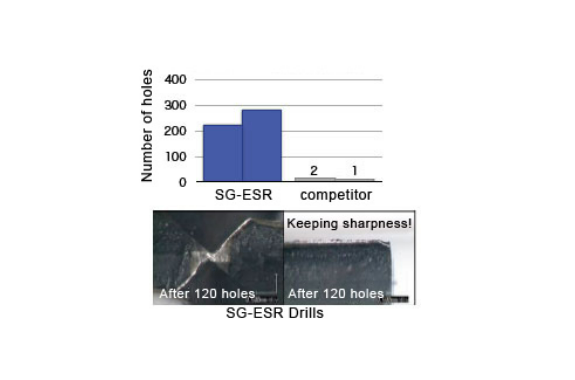

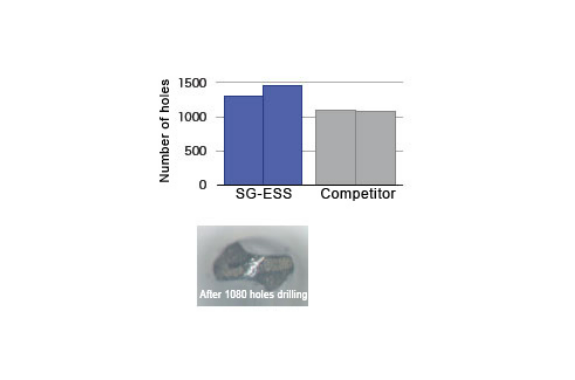

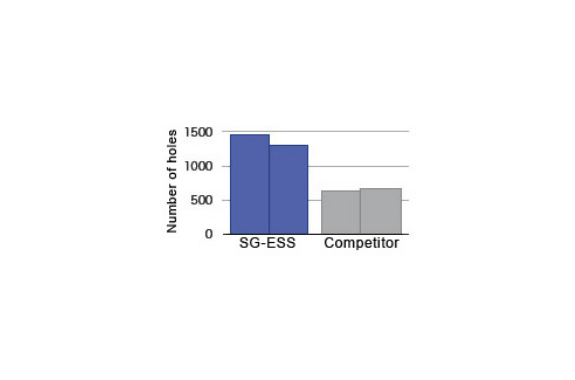

Appication example : Tool life comparison SGESS

Tool Life Comparison – Ø0.5 mm

Tool: 0.5 mm

Cutting Speed: 8 m/min

Feed: 51 mm/min (0.01 mm/rev)

Work Material: SUS304

Hole Depth: 1.5 mm Blind Hole (0.25 mm Step)

Coolant: Water-soluble

Tool Life Comparison – Ø0.9 mm

Tool: 0.99 mm

Cutting Speed: 10 m/min

Feed: 64 mm/min (0.02 mm/rev)

Work Material: SUS304

Hole Depth: 3 mm Blind Hole (0.5 mm Step)

Coolant: Water-soluble

Tool Life Comparison – Ø0.5 mm

Tool: 0.5 mm

Cutting Speed: 25 m/min

Feed: 320 mm/min (0.02 mm/rev)

Work Material: S50C (180HB)

Hole Depth: 1.5 mm Blind Hole

Coolant: Water-soluble

Tool Wear Comparison After 8320 Holes – Ø0.9 mm

Tool: 0.99 mm

Cutting Speed: 30 m/min

Feed: 250 mm/min (0.03 mm/rev)

Work Material: S50C (180HB)

Hole Depth: 3 mm Blind Hole

Coolant: Water-soluble