Japan, Naigai Rubber Industry Co.,Ltd

Naigai Floats Rubber

Made in Japan

Manufacturer: Naigai Rubber Industry Co.,Ltd

Features

Floats are closed pore foam devices composed of NBR rubber and phenol resin. They are excellent in terms of oil resistance and dimensional stability.

| NBR…Ebonite containing a large amount of crosslinking agent (sulfur) * Phenol resin…Thermosetting resin | Forms rigid foam |

*Ebonite in which most of the rubber reaction points have reacted with sulfur.

It is an aggregate of closed-pore foams filled with cracked gases generated from float containing foaming agents.

Its structure is just like a big balloon made of a collection of small balls.

NBR is a representative oil resistant (anti non-polar solvent) synthetic rubber. Therefore, it shows excellent resistance to non-polar media such as gasoline, light oil and kerosene.

Cross section of float (closed pores)

Applications

– Fuel tank level gauges (automobiles, motorcycles)

– Carburetors (Motorcycles, agricultural machine engines)

– Engine oil level gauges

– Pneumatic auxiliary components (auto drain)

– Kerosene stove level gauges

– Other types of equipment that need level detection sensors

Manufacturing method

We have floats with the following manufacturing method.

| Type | Molding Method | Composition (raw material) |

| Closed pore foam | High pressure double-stage foaming | NBR/Phenol |

| Single-stage foaming | Urethane | |

| Resin injection foaming | PP/Nylon | |

| Hollow body | Molded item joint | POM/PP, etc |

| Blow molding | PP・PE |

With this float manufacturing method, we use high-pressure and double-stage foaming where vulcanization and foaming are processed in the two stages of vulcanization: primary vulcanization and secondary vulcanization.

The features of two-stage foaming are described as follows.

- The floats have almost perfect closed pores. Therefore, they can keep floating without allowing liquid to get inside even when they have a damaged appearance.

- Two-stage foaming enables productization of highly foamed products. (A minimum specific gravity of about 0.15 is available.) However, products with a low specific gravity show a lower performance in terms of oil resistance, etc.

- Subsequent processes such as cutting, drilling and bonding are easy.

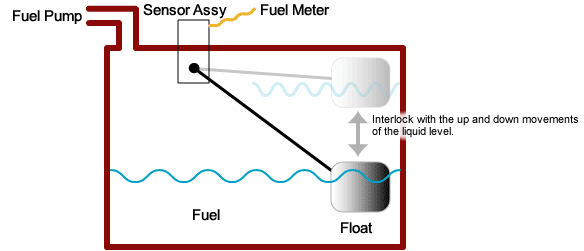

What is a tank float?

A tank float is part of a device that measures the fuel level based on the up and down movements of the liquid level.

They need to be excellent in terms of oil resistance and durability because they are used in fuels (gasoline, light oil, etc.)

History of floats

- Floats used to be made of natural materials such as cork and wood. Problem: Low performance (shape, weight, oil resistance)

- Metallic hollow objects (hollow objects made from welded and sealed processed metallic shells)Problems: Large variation in the strength of the welded and joined sections.

Peeling of joined sections due to impact

Irregular shaped molded products and small and lightweight products cannot be manufactured.

- Conversion to high-polymer materials (rubber, plastic)

Related Products

-

Chiyoda Seiki Strong-25 Cutting Machine For Cutting Medium To Heavy Materials (Per 3 steps)

-

Kansai SUS304 BB/SUS304 BC Shackle M Class JIS Standard Shackle

-

Furuto Industrial (Monf) No.6022 OPP Tape

-

Nachi Solenoid Valve For Automobile

-

Ross Asia Safety Air Entry Assembly with DMC Series Safety Exhaust Valve Safety cat. 4 PL e, internal monitoring

-

Chiyoda Seiki General-purpose Pressure Regulator For Cylinders Stout (for oxygen and acetylene) With Built-in Dry Safety Device