Japan, Naigai Rubber Industry Co.,Ltd

Naigai Hanenite Anti-vibration Rubber

Made in Japan

Manufacturer: Naigai Rubber Industry Co.,Ltd

Product name: Hanenite Anti-vibration Rubber

HANENITE vibration suppression rubber has excellent performances of absorbing shocks and vibrations. Even when an external force is applied, the rubber absorbs the energy with almost no repulsion. Moreover, the material boasts excellent physical properties and durability, on par with those of normal rubber. As a result, this rubber does not bounce when it falls, defying the conventional expectations of rubber’s behavior.

・Excellent vibration damping performance at room temperature (5 to 35℃)!

The repulsion elasticity is less than 10%, excluding CP-S, indicating a significantly reduced bounce-back effect in comparison to other materials.

・A lineup with +α characteristics!

Excluding CP, the capability to cut and punch sheet materials remains achievable, thus enhancing its versatility in practical applications.

CP-S: Can be used up to -20℃.

・Free shapes created by excellent workability!

This material can be molded using the same methods applied to general rubber, demonstrating its flexible manufacturing potential.

Strong adhesion to metal is possible.

Apart from CP, the ability to cut and punch sheet materials is indeed possible, thereby broadening its range of practical uses.

The sponge sheet is notably lightweight!

Closed cell vibration damping sponge with a specific gravity of 0.3.

・Environmental measures initiatives

Rohs Directive: Compatible with all grades

REACH regulations: Compliant except for flame retardant grades (GP-40HBE, GP-50V)

Examples of commonly used locations

・For impregnation of motor coils for air conditioners and refrigerators

・For coil impregnation of other sealed motors, etc.

| Usage form | Target example | Main features | Application example |

| supporting parts | Precision equipment support material | vibration isolation | OA printer legs, facsimile legs |

| Vibrating body support material | VTR motor mount | ||

| Washing machine rubber legs, industrial sewing machine legs | |||

| impact insulation | Commercial mochi pounding machine support legs | ||

| Vibration isolation/resonance prevention | Parts feeder anti-vibration mat | ||

| floating floor supports | impact insulation | Soundproof/vibration proof floor support rubber, OA floor | |

| AV equipment support material | Vibration isolation/resonance prevention | VTR rubber legs, anti-vibration rubber for in-vehicle AV equipment | |

| CD player insulator | |||

| Laminated members | shoe midsole | shock absorption | Golf shoes, luxury women’s shoes |

| Cushioning material for sports | baseball glove internal cushion | ||

| vibration damping sheet | vibration absorption | Handy VTR built-in motor section | |

| Buffer member | Vibrating body holding grip | vibration isolation | Impact wrench, brush cutter, jackhammer |

| memory foam stopper | Collision object low rebound stop | Automatic production line/parts tray | |

| Rubber for pachinko ball stoppers | |||

| Vending machine coin stopper | |||

| memory foam cushion | Impact acceleration reduction | Keyboard, PPC development section | |

| Printer head section | |||

| Passenger car center console part | |||

| impact insulation | rubber seal | vibration isolation | Industrial sewing machine table part |

| CT scanner camera mounting part | |||

| holder | impact insulation | hand microphone internal holder | |

| Microphone holder with built-in radio cassette player |

Varieties and characteristics

*GP-50V is a UL94-V0 compliant product. GP-40HBE is equivalent to UL94-HB.

| Product type | Unit | |||||||||

| GP 35LE | GP 60LE | MP40 | CP40S | CP55S | GP 40HB | GP50V | OP40 | Sponge | ||

| Mechanical properties | ||||||||||

| Hardness (typeA) | 33 | 49 | 39 | 36 | 49 | 43 | 50 | 35 | 24 (SRIS C) | |

| Tensile strenght | Mpa | 11.9 | 8.5 | 6.0 | 8.8 | 9.8 | 8.1 | 7.2 | 14.7 | 1.5 |

| 〃 | kgf /cm2 | 121 | 87 | 61 | 90 | 100 | 83 | 73 | 150 | 15 |

| Elongation | % | 790 | 630 | 500 | 1000 | 830 | 700 | 710 | 820 | 500 |

| Tear strengh | kN /m | 15.4 | 19.2 | 16.9 | 22.4 | 25.6 | 15.5 | 16.4 | 19.7 | 6.2 |

| 〃 | kgf /cm | 15.7 | 19.6 | 17.2 | 22.8 | 26.1 | 15.8 | 16.7 | 20.1 | 6.3 |

| Repilsion slasticity | % | 2 | 4 | 4 | 10 | 10 | 5 | 5 | 9 | 5 |

| Compression permanent set | % | 9 | 18 | 13 | 29 | 25 | 11 | 25 | 9 | – |

| Static shear elastic modulus | Mpa | 0.17 | 0.41 | 0.27 | 0.23 | 0.44 | 0.38 | 0.43 | 0.30 | 0.04 |

| 〃 | kgf /cm2 | 1.7 | 4.2 | 2.8 | 2.3 | 4.5 | 3.9 | 4.4 | 3.9 | 0.74 |

| Specific gravity | 1.26 | 1.27 | 1.35 | 1.09 | 1.2 | 1.35 | 1.4 | 1.18 | – | |

| Heat resistance Air-heated aging test conditions:70℃×96Hr | ||||||||||

| Rate of change in strength | % | -7 | -8.1 | -11 | -3 | +2 | -2 | +3 | +1 | -2.0 |

| Rate of change in elongstion | % | -1.7 | -7.0 | -6.9 | +16 | -8.1 | +16 | +18 | -38 | +170 |

| change in hardness | % | +2 | +16 | +8 | +3 | +2 | -2 | +3 | +1 | – |

| Oilproof and waterproof Swelling test conditions:Weight change rate (%)after 40℃×24Hr | ||||||||||

| JIS#1 Oil | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| JIS#3 Oil | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| Fuel C | ○ | ○ | × | × | × | × | ○ | ○ | × | |

| Fuel D | ○ | ○ | × | × | × | × | ○ | ○ | × | |

| Pure wate | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| Cold-resistance Tg(℃) 100Hz | ||||||||||

| Tg | ℃ | 18 | 21 | 12 | -9 | 10 | 11 | 11 | 15 | 20 |

| Ozone-resistance Ozon-resistance test conditions:50pphm×40℃×20%elongation | ||||||||||

| 24Hr | N.C. | N.C. | N.C. | C-4 | N.C. | A-1 | C-4 | N.C. | N.C. | |

| 48Hr | A-1 | B-1 | N.C. | – | C-3 | A-1 | – | N.C. | N.C. | |

| 96Hr | A-2 | B-3 | N.C. | – | – | A-2 | – | N.C. | N.C. | |

※Test methods compliand with the standards shown on the right.

※The measurement values are not guranteed performance values.

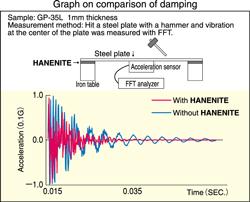

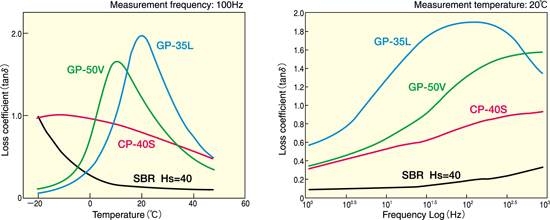

Vibration supperession performances

Standard sheet size table

| GP35LE | GP60LE | MP40 | CP40S (BTO | CP55S (BTO | OP40 | GP40HB | GP50V | Sponge | |

| Thickness(mm) Depth*width(mm) | |||||||||

| 0.5 | 350*500 | – | – | – | – | – | – | 350*500 | – |

| 1 | 350*500 | 350*500 | 250*250 | 250*250 | 250*250 | 350*500 | 350*500 | 350*500 | 350*500 |

| 1.5 | – | – | – | – | – | – | 350*500 | 350*500 | 350*500 |

| 2 | 350*500 | 350*500 | 350*500 | 250*250 | 250*250 | 350*500 | 350*500 | 350*500 | 350*500 |

| 3 | 350*500 | 350*500 | 350*500 | 250*250 | 250*250 | 350*500 | 350*500 | 350*500 | 350*500 |

| 5 | 350*500 | 350*500 | 350*500 | 250*250 | 250*250 | 350*500 | 350*500 | – | 350*500 |

| 10 | 350*500 | 350*500 | 350*500 | 250*250 | 250*250 | 350*500 | – | – | 350*500 |

| 12 | – | – | – | – | – | – | – | – | 350*500 |

| 15 | 250*250 | 250*250 | 250*250 | 250*250 | 250*250 | – | – | – | – |

| 20 | 250*250 | 250*250 | 250*250 | 250*250 | 250*250 | – | – | – | – |

| 30 | 250*250 | 250*250 | – | 250*250 | 250*250 | – | – | – | – |

Related Products

-

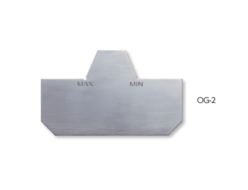

Niigata Seiki OG-1/ OG-2 Gasket Limit Gauge

-

Chiyoda Tsusho HS4/6/8/10/12-OOU SUS316 Union Connector

-

TSUBOSAN Round Engineer’s Files

-

LOBTEX DLM-U Electric Drill Socket Universal Type

-

Eisen IV Series Electroplated Tool For Chamfering Glass Drill

-

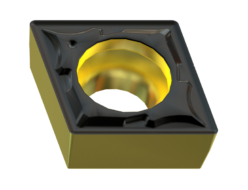

SAKUSAKU DCMT070204-UG Turning Insert 55° Rhombic/7° Positive