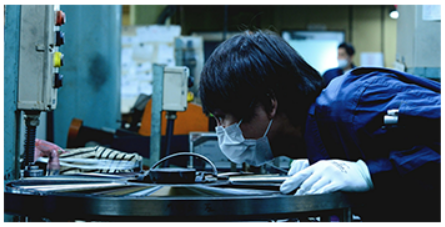

Back in 1992, Nakayama began developing cutting rules that resist breakage even when bent—based on customer demand. The process took years of trial and error, as coarse grinding wheels caused cracks. So we switched to fine wheels, gradually refining the blade and eliminating grooves. The result was a polished, flexible, and razor-sharp edge—named “MIR,” short for “mirror.” We also engineered custom grinding wheels exclusively for MIR, ensuring its unmatched quality and consistency today.

MIR (Center Bevel)

| COIL WINDING | ITEM | THICKNESS | HEIGHT (mm) | HARDNESS(HS) | COLOR | EDGE ANGLE | CODE |

|---|

| BODY | EDGE |

|---|

| A470 | MIR60 | 0.7 | 23.6 | 45 | 72 | ff Blue | 43° | 318767 |

| ACE80-MIR | 0.7 | 23.6 | 45 | 75 | S Silver | 43° | 318663 |

| ST-MIR1O | 0.7 | 23.5 | 45 | 80 | 6 Silver | 43° | 317061 |

| MIR20 | 0.7 | 23.6 | 45 | 80 | Silver | 43° | 318605 |

| MIR23 | 0.7 | 23.6 | 45 | 80 | 6 Silver | 30° | 318758 |

| MIR-CI23 | 0.7 | 23.6 | 50 | 75 | 6 Silver | 30° | 318643 |

| ST-MIR CJ10 | 0.7 | 23.5 | 50 | 80 | 6 Silver | 43° | 316939 |

| ST-ACE8O-MIR | 0.7 | 23.6 | 45 | 75 | 6 Silver | 43° | 316866 |

| ST-MIR20 | 0.7 | 23.6 | 45 | 80 | Silver | 43° | 316878 |

| ST-MIR23 | 0.7 | 23.6 | 45 | 80 | 6 Silver | 30° | 316881 |

| B470 | ACE80-MIR | 0.7 | 23.6 | 45 | 75 | B Silver | 43° | 318766 |

| MIR20 | 0.7 | 23.6 | 45 | 80 | 6 Silver | 43° | 318608 |

| NC-MIR | 0.7 | 23.6 | 50 | 75 | 6 Silver | 43° | 318624 |

| MIR-CI23 | 0.7 | 23.6 | 50 | 75 | 6 Silver | 30° | 319924 |

| ST-MIR CJ10 | 0.7 | 23.5 | 50 | 80 | 6 Silver | 43° | 316988 |

| ST-ACE8O-MIR | 0.7 | 23.6 | 45 | 75 | 6 Silver | 43° | 316865 |

| ST-MIR20 | 0.7 | 23.6 | 45 | 80 | B Silver | 43° | 316879 |

| ST-MIR CI20 | 0.7 | 23.6 | 50 | 75 | 6 Silver | 43° | 316867 |

| ST-MIR CJ20 | 0.7 | 23.6 | 50 | 80 | 6 Silver | 43° | 316868 |

| ST-MIR EJ20 | 0.7 | 23.6 | 60 | 80 | Silver | 43° | 316876 |

| ST-MIR EJ23 | 0.7 | 23.6 | 60 | 80 | B Silver | 30° | 316882 |

| ITEM | THIKNESS(mm) | HEIGHT(mm) | HARDNESS(HS) | COLOR | EDGE ANGLE | LENGTH(mm) | CODE |

|---|

| BODY | EDGE |

|---|

| MIR10 | 0.7 | 23.5 | 45 | 80 | Silver | 43° | 909 | 318601 |

| MIR13 | 0.7 | 23.5 | 45 | 80 | Silver | 30° | 909 | 318606 |

| MIR60 | 0.7 | 23.6 | 45 | 72 | Blue | 43° | 909 | 318646 |

| ACE80-MIR | 0.7 | 23.6 | 45 | 75 | Silver | 43° | 909 | 318661 |

| MIR20 | 0.7 | 23.6 | 45 | 80 | Silver | 43° | 909 | 318611 |

| MIR23 | 0.7 | 23.6 | 45 | 80 | Silver | 30° | 909 | 318616 |

| MIR-CI23 | 0.7 | 23.6 | 50 | 75 | Silver | 30° | 909 | 318633 |

| MIR-CI23 | 0.7 | 23.6 | 50 | 75 | Silver | 30° | 1500 | 319331 |

| STA04-MIR | 0.45 | 23.6 | 50 | 72 | Blue | 30° | 1500 | 306394 |

| ST-MIR CJ10 | 0.7 | 23.5 | 50 | 80 | Silver | 43° | 909 | 317063 |

| ST-MIR20 | 0.7 | 23.6 | 45 | 80 | Silver | 43° | 909 | 316815 |

| ST-MIR CJ20 | 0.7 | 23.6 | 50 | 80 | Silver | 43° | 909 | 316808 |

| ST-MIR CJ23 | 0.7 | 23.6 | 50 | 80 | Silver | 30° | 909 | 316813 |

| ST-MIR EJ20 | 0.7 | 23.6 | 60 | 80 | Silver | 43° | 909 | 316979 |

| ST-MIR EJ23 | 0.7 | 23.6 | 60 | 80 | Silver | 30° | 909 | 316817 |

| SK-MIR | 0.7 | 23.6 | 72 | 80 | Brown | 30° | 1200 | 362912 |

MIR Double Long Bevel

| ITEM | THICKNESS(mm) | HEIGHT(mm) | HARDNESS(HS) | COLOR | EDGE ANGLE | LENGTH(mm) | CODE |

|---|

| BODY | EDGE |

|---|

| SHD-MIR | 0.45 | 18.5 | 72 | 88 | Brown | 28° | 1220 | 362810 |

| SHD-MIR | 0.45 | 18.5 | 72 | 88 | Brown | 33° | 1220 | 362831 |

| NCD05-MIR | 0.5 | 23.6 | 50 | 80 | S Silver | 42° | 909 | 309563 |

| STD07-MIR 18P | 0.7 | 23.6 | 60 | 75 | 6 Silver | 28° (18P) | 1500 | 316414 |

MIR Side Double Long Bevel

This is a side double long bevel cutting rule with the second step also mirror-finished. One side is finished at an acute angle, resulting in a straight cross section. Since the cutting edge is at the center position, there is no need to adjust CAD data.

| ITEM | THICKNESS(mm) | HEIGHT(mm) | HARDNESS(HS) | COLOR | EDGE ANGLE | LENGTH(mm) | CODE |

|---|

| BODY | EDGE |

|---|

| NCF07-W-MIR | 0.7 | 23.6 | 50 | 75 | W Blue | 36° | 909 | 318960 |

| 0.7 | 23.6 | 50 | 75 | H Blue | 36° | 1500 | 318961 |