Facilities, Japan, Namita Kiko, Retainers

Namita Kiko Retainers

Product Made in Japan

Manufacturer: Namita Kiko

Model: Namita Kiko Retainers

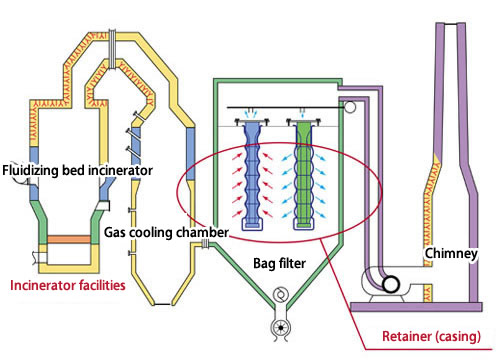

In a wide range of production and processing processes of mining, refining, cement creation, chemical processing, steel processing, or refuse processing, materials such as soot and smoke and dioxins are produced during the combustion process in exhaust gas, and general particulates are also produced during the fracturing/crushing process. Retainers installed in bag type dust collectors are used for supporting filter cloths that filter such materials or general particulates so that the collection effect can be maintained when such materials or general particulates are filtered.

Features

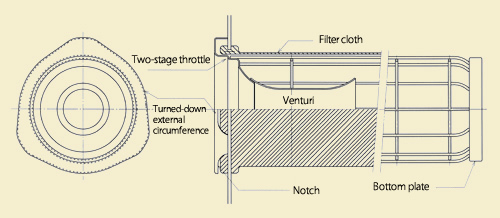

New epoch-making venturi axes.

Two stage throttle effects

The upper external fringe with a two-stage throttle structure is effective for preventing the filter cloth from coming off.

Any of the existing filter cloth installation methods (with or without collars) is supported.

Turn down outer circumference effects

The turned-down outer circumference reinforces the entire venturi. This increases the venturi strength significantly, resulting in eliminating any damage to occur in various works done on site.

Notch Effects

The installation status of the filter cloth can be checked while the retainer is set.

The retainer can be moved up and down easily by using notches even without using handles. This enhances the workability when an inspection is conducted.

NAMITA’s triangle venturi :

Energy Saving Type Effects

Making bypass opening with pulse jet at locations where the venturi effect can be secured increases the suction area for dust collection and decreases pressure loss. At the same time, this venturi is also equipped with the shaking-off function on the upper part of the filter cloth.

Related Products

-

Kobata FS Series Float Switch

-

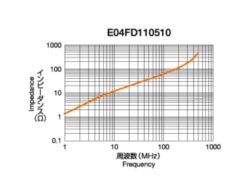

Seiwa E04FD110510 FD Type Ferrite Cores for FPC

-

TSUBOSAN 8-PCS./LENGTH 180mm Half Round Precision Needle Files

-

ASCO Digital Direct Acting Electropneumatic Regulator SENTRONIC-D

-

Chiyoda Seiki SG-32B Small/Medium/Large flow/Pressure regulator/Governor Small/medium/large flow Rate Governor (primary pressure: 0.5 to 30.0 kPa/set pressure 0.25 to 20.0 kPa)

-

Vessel No.900 MEGADORA Standard Screwdriver