Naniwa

Naniwa Eyebolt

Manufacturer : Naniwa

Model: Eyebolt

Material: SS400, SUS304/SUS316L, S45CⒽ, SCM435Ⓗ (SS400 is available in stock with Unichrome, Chromate, Trivalent Chromate, and Hot-dip Galvanizing finishes. For other surface treatments (plating), please inquire.)

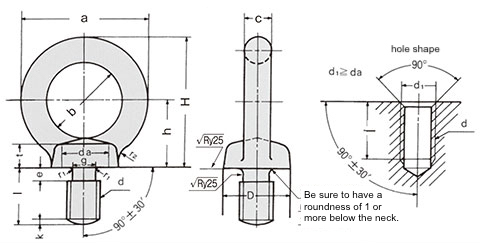

*Blue belts are JIS standard dimensions. (Unit: mm)

| Nominal size of screws | a | b | c | D | t | h | H(reference) |

|---|---|---|---|---|---|---|---|

| M5 | 26 | 16 | 5 | 13 | 4.9 | 13.5 | 26.5 |

| M6 | 26 | 16 | 5 | 13 | 4.9 | 13.5 | 26.5 |

| M8 | 32.6 | 20 | 6.3 | 16 | 5 | 17 | 33.3 |

| M10 | 41 | 25 | 8 | 20 | 7 | 21 | 41.5 |

| M12 | 50 | 30 | 10 | 25 | 9 | 26 | 51 |

| M14 | 60 | 35 | 12.5 | 30 | 11 | 30 | 60 |

| M16 | 60 | 35 | 12.5 | 30 | 11 | 30 | 60 |

| M18 | 72 | 40 | 16 | 35 | 13 | 35 | 71 |

| M20 | 72 | 40 | 16 | 35 | 13 | 35 | 71 |

| M22 | 81 | 45 | 18 | 40 | 15 | 40 | 80.5 |

| M24 | 90 | 50 | 20 | 45 | 18 | 45 | 90 |

| M27 | 110 | 60 | 25 | 60 | 22 | 55 | 110 |

| M30 | 110 | 60 | 25 | 60 | 22 | 55 | 110 |

| M33 | 110 | 60 | 25 | 60 | 22 | 55 | 110 |

| M36 | 133 | 70 | 31.5 | 70 | 26 | 65 | 131.5 |

| M39 | 133 | 70 | 31.5 | 70 | 26 | 65 | 131.5 |

| M42 | 151 | 80 | 35.5 | 80 | 30 | 75 | 150.5 |

| M45 | 151 | 80 | 35.5 | 80 | 30 | 75 | 150.5 |

| M48 | 170 | 90 | 40 | 90 | 35 | 85 | 170 |

| M52 | 170 | 90 | 40 | 90 | 35 | 85 | 170 |

| M56 | 210 | 110 | 50 | 110 | 42 | 105 | 210 |

| M64 | 210 | 110 | 50 | 110 | 42 | 105 | 210 |

| M80X6 | 266 | 140 | 63 | 130 | 50 | 130 | 263 |

| (M90X6) | 302 | 160 | 71 | 150 | 55 | 150 | 301 |

| M90X6 | 340 | 180 | 80 | 170 | 60 | 165 | 335 |

| M100X6 | 340 | 180 | 80 | 170 | 60 | 165 | 335 |

| M110X6 | 380 | 200 | 90 | 190 | 72 | 190 | 380 |

| Nominal size of screws | I | e | g(minimum) | r1(minimum) | da(minimum) |

|---|---|---|---|---|---|

| M5 | 12.5 | 3 | 3.9 | 0.8 | 7.1 |

| M6 | 12.5 | 3 | 4.5 | 0.8 | 7.1 |

| M8 | 15 | 3 | 6 | 1 | 9.2 |

| M10 | 18 | 4 | 7.7 | 1.2 | 11.2 |

| M12 | 22 | 5 | 9.4 | 1.4 | 14.2 |

| M14 | 27 | 5 | 11.1 | 1.5 | 16.2 |

| M16 | 27 | 5 | 13 | 1.6 | 18.2 |

| M18 | 30 | 6 | 14.4 | 2 | 20.2 |

| M20 | 30 | 6 | 16.4 | 2 | 22.4 |

| M22 | 35 | 7 | 18.3 | 2.3 | 24.4 |

| M24 | 38 | 8 | 19.6 | 2.5 | 26.4 |

| M27 | 45 | 8 | 22.6 | 2.5 | 29.4 |

| M30 | 45 | 8 | 25 | 3 | 33.4 |

| M33 | 45 | 8 | 27.3 | 3 | 36.4 |

| M36 | 55 | 10 | 30.3 | 3 | 39.4 |

| M39 | 55 | 10 | 33 | 3.5 | 43 |

| M42 | 65 | 12 | 35.6 | 3.5 | 45.6 |

| M45 | 65 | 12 | 38 | 3.5 | 49 |

| M48 | 70 | 12 | 41 | 4 | 52.6 |

| M52 | 70 | 12 | 44.9 | 4 | 56.8 |

| M56 | 80 | 14 | 48.3 | 4.5 | 61 |

| M64 | 90 | 14 | 55.7 | 5 | 71 |

| M80X6 | 105 | 14 | 71 | 5 | 87 |

| (M90X6) | 120 | 14 | 81 | 5 | 97 |

| M90X6 | 130 | 14 | 81 | 5 | 97 |

| M100X6 | 130 | 14 | 91 | 5 | 108 |

| M110X6 | 140 | 14 | 100 | 5.3 | 118 |

| Nominal size of screws | r2(approximately) | k(approximately) | Working Load | Weight (kg) | |

|---|---|---|---|---|---|

| Vertical lift 45-degree lift (per 2 pieces) | |||||

| kgf | kN | ||||

| M5 | 2 | 1 | 40 | 0.392 | 0.014 |

| M6 | 2 | 1 | 60 | 0.588 | 0.015 |

| M8 | 4 | 1.2 | 80 | 0.785 | 0.03 |

| M10 | 4 | 1.5 | 150 | 1.47 | 0.06 |

| M12 | 6 | 2 | 220 | 2.16 | 0.12 |

| M14 | 6 | 2 | 330 | 3.23 | 0.2 |

| M16 | 6 | 2 | 450 | 4.41 | 0.22 |

| M18 | 8 | 2.5 | 540 | 5.29 | 0.37 |

| M20 | 8 | 2.5 | 630 | 6.18 | 0.4 |

| M22 | 10 | 2.5 | 790 | 7.74 | 0.57 |

| M24 | 12 | 3 | 950 | 9.32 | 0.8 |

| M27 | 15 | 3 | 1,200 | 11.7 | 1.5 |

| M30 | 15 | 3.5 | 1,500 | 14.7 | 1.54 |

| M33 | 15 | 4 | 1,900 | 18.6 | 1.59 |

| M36 | 18 | 4 | 2,300 | 22.6 | 2.83 |

| M39 | 18 | 4 | 2,850 | 27.9 | 2.9 |

| M42 | 20 | 4.5 | 3,400 | 33.3 | 4.1 |

| M45 | 20 | 4.5 | 3,950 | 38.7 | 4.34 |

| M48 | 22 | 5 | 4,500 | 44.1 | 5.88 |

| M52 | 22 | 5 | 5,600 | 54.9 | 6.16 |

| M56 | 25 | 5 | 6,750 | 66.2 | 10.85 |

| M64 | 25 | 6 | 9,000 | 88.3 | 11.6 |

| M80X6 | 35 | 6 | 15,000 | 147 | 21.5 |

| (M90X6) | 35 | 6 | 18,000 | 177 | – |

| M90X6 | 35 | 6 | 18,000 | 177 | 44 |

| M100X6 | 40 | 6 | 20,000 | 196 | 46.5 |

| M110X6 | 45 | 8 | 22,000 | 215 | 65 |

*We also have a wide range of products in Whitworth (BSW), UNC (Unified Coarse), and fine-pitch threads.