Japan

NCP Quick-Drying Pilelock

Product Made In Japan

Manufacturer: NCP

Overview

1. It is proud of 3000 and more use result with the swelling water tightness material

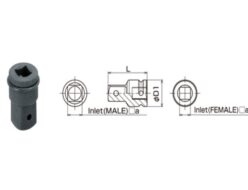

Pilelock is used for the following work, and evaluated very high. Debris processing place, shore protection works. The deadline work of the ocean and the river. Then, the excavation work follows for the building construction and the water pipe plant work.

2. The water tightness of the steel sheet-pile is enhanced remarkably.

The dry paint film of the Pilelock does water absorption swelling. Then, an opening in the steel sheet-pile joint part is filled up, and the effect on water tightness is enhanced remarkably.

3. Application can do it if it is painted on the day before blowing.

How to use Pilelock is very easy. It is painted in both tabs of the steel sheet-pile, and it dries it for more than 10 hours. The application can do it in the same way as the usual steel sheet-pile, and then high watertightness are shown after that.

4. It is excellent in the removal after the work completion and the cleaning.

Pilelock is excellent in a pulling out to remove steel sheet-pile after the work completion. Then, it is excellent in the cleaning of the dry paint film which has been used as well.

5. Pilelock acquires a patent in Japan.

Pilelock is the patent product developed in 1968. Then, the patent which improvement was piled up to is acquired after that as well.

Watertightness mechanics

1. Pilelock is painted in the joint part (tab) of the steel sheet-pile, and it becomes the tenacious dry paint film which has elasticity when it is made to do natural seasoning.

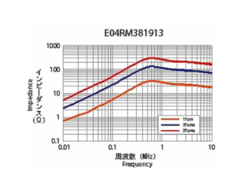

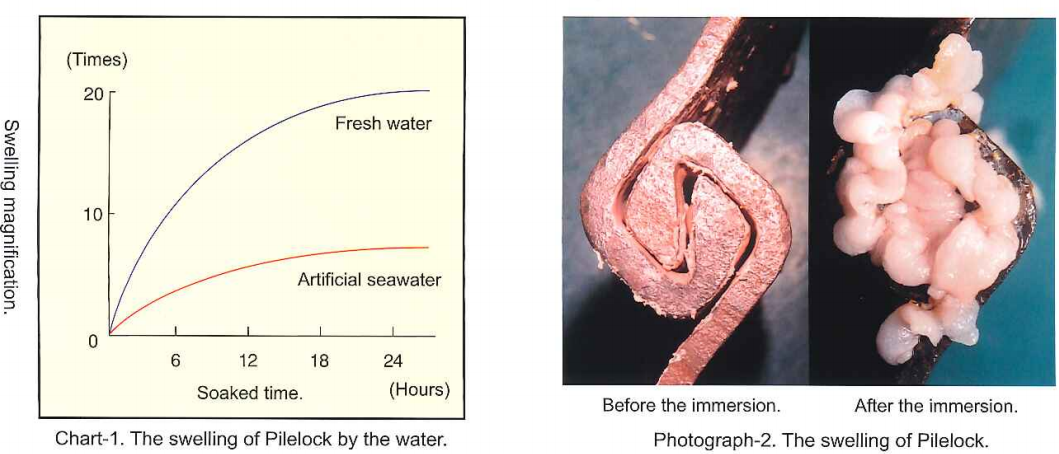

2. When this is soaked in the water, it begins to do swelling in 1-2 hours, and water absorption swelling is done in about 20 times after 24 hours. Swelling magnification is dry paint film and the weight ratio of the dry paint film after the swelling.

(Refer to chart-1 for the length of the time when dry paint film was soaked and the relations of the swelling weight magnification.)

3. Pilelock fills up an opening in the steel sheet-pile joint part (tab) due to this swelling. Therefore steel sheet-pile can be watertightnessed, and the performance that it stands the hydraulic pressure of 500kPa (5kgf/cm2](It is equivalent to the pressure of the underwater bottom 50m.) and more is shown.

(Photograph-2 showed the water swelling change in state of the dry paint film before and after the retting. Pilelock was painted in the steel sheet-pile tab, and it engaged it after the drying, and soaked for the underwater.

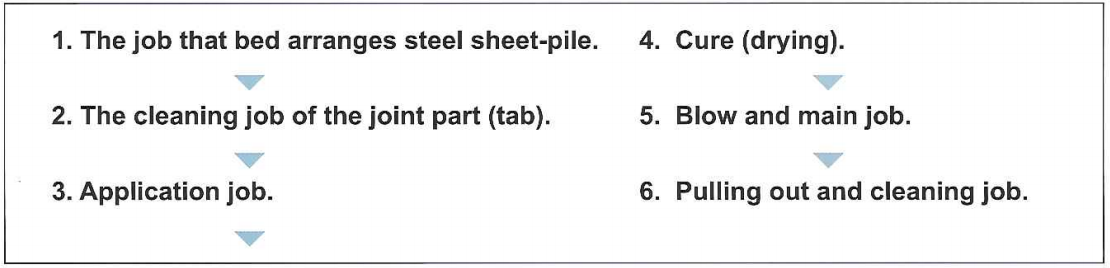

The procedure of the Pilelock application

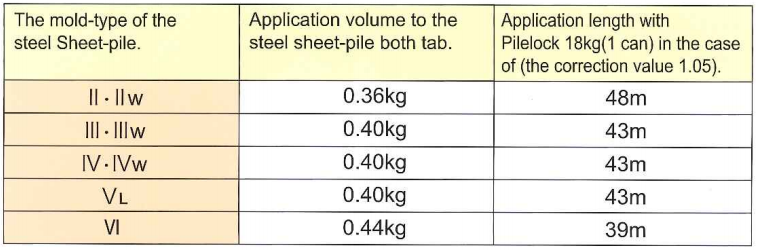

Application Volume

Packing

Pilelock 18kg Oil can

Pilelock thinner 16L Oil can