- Home

- Products

- NDV Pneumatically Operated ON-OFF Valve (double acting) VPN1100ND type V-port Valves (V100 type)

Japan, NIPPON DAIYA VALUE Co.

NDV Pneumatically Operated ON-OFF Valve (double acting) VPN1100ND type V-port Valves (V100 type)

Made in Japan

Manufacturer: NIPPON DAIYA VALUE Co., Ltd.

Model: Pneumatically Operated ON-OFF Valve (double acting) VPN1100ND type

NDV provides various types of ball valves suitable for a wild range of fields.

It is possible to select from a wide range of lineups such as multi-way valves and V-port valves to suit your application, in addition to the standard fire-safe type.

We also apply requests for special purpose valves used under high pressure and those for shield machine and nuclear power plants.

Structure and Features of V-Port Valve (V100 type)

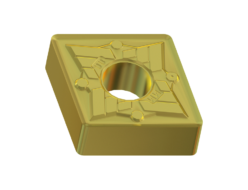

①V-cut ball

Ball of the V-port valve

Since the opening side of the hemispherical ball is cut into a V-shape, it has the effect of cutting fiber and solid matter.

Stellite is also applied to the sealing surface of the ball, and it is lapped, so it has excellent abrasion resistance (hard chrome plating is applied for the soft seat).

②Pocketless structure

The valve seat exists at primary surface only, so fluid will not accumulate in the valve flow path or become clogged between the ball and the body.

Also, this primary side seal structure does not cause abnormal pressure rise.(There exist restrictions on the flow direction. Details are here.)

③Seat with excellent heat resistance and wear resistance

The seat combines rigidity and flexibility to seal from vacuum to high pressure due to the effect of temperature and pressure difference. Metal seats allow use up to high temperatures.

It is also wear-resistant against abrasive fluids such as slurry and powder.

④Stable bearing function

Specially reinforced PTFE is used for the radial bearings of the stem and trunnion. Therefore, the operating torque is low and it can withstand high frequency operation.

⑤Gland packing with excellent sealing performance

V-packing provides complete sealing from vacuum to high pressure (V100ND type).

⑥Integrated body

Since the valve body is integrated, there is no fluctuation of valve torque due to piping stress, deterioration of sealing performance, or external leakage.

⑦Full flow

When the valve is fully open, the valve body is almost straight without obstructing the flow, so the pressure loss is small. In addition, it is possible to smoothly pass slurry, etc., which makes it difficult to cause fluid clogging and cavitation.

⑧Excel in flow regulation

Since the ball is V-cut, the rangeability is high and the flow rate control performance is excellent.

The specific flow characteristics are nearly equal percent.

Applicable field

Paper mills (pulp liquid, etc.), slurries (iron oxide, mud, lime milk, etc.), powders (fly ash, resin pellets such as nylon, etc.), highly viscous fluids, etc.