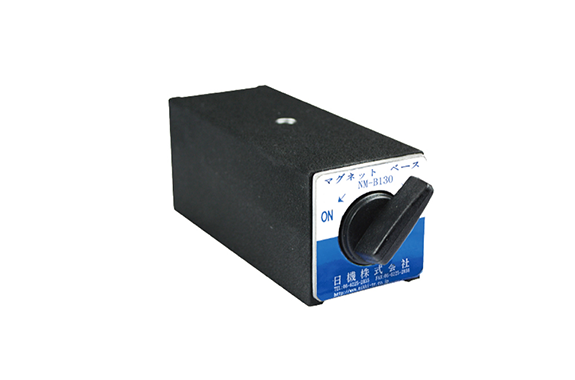

Nikki Co., Ltd.

Nikki Magnet Base

Manufacturer: Nikki Co., Ltd.

Magnet base features

Magnet material

Ferrite magnets are used, which are resistant to rust and impact and do not weaken easily.

Adhesive surface

As long as the V-shaped or concave magnet can be stably attached, it can be fixed to any surface, whether flat or curved.

How to use the magnet base

By attaching a jig that suits the intended use to the screw hole part, it can also be used for purposes other than measurement.

A standard magnet base. The adhesive force is 300N to 1500N, and it has an M screw hole so that you can attach a jig or arm according to your application.

| Model | NM-B30 |

|---|---|

| size | 35 x 30 x 35 (H) mm |

| Screw Hole Dimensions | M5x0.8P |

| Maximum suction force | 300N |

| Adhesive surface | Bottom (V-shaped)/Rear |

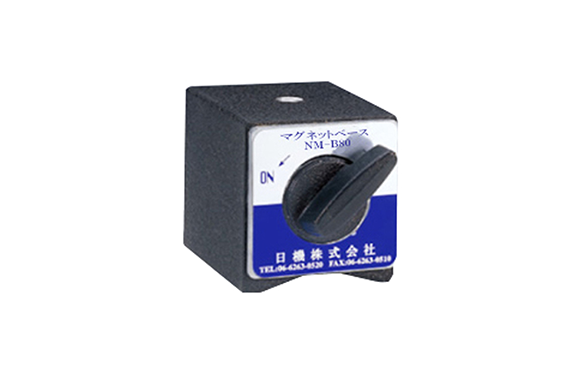

| Model | NM-B80 |

|---|---|

| size | 60 x 50 x 55 (H) mm |

| Screw Hole Dimensions | M8x1.25P |

| Maximum suction force | 800N |

| Adhesive surface | Bottom (V-shaped)/Rear |

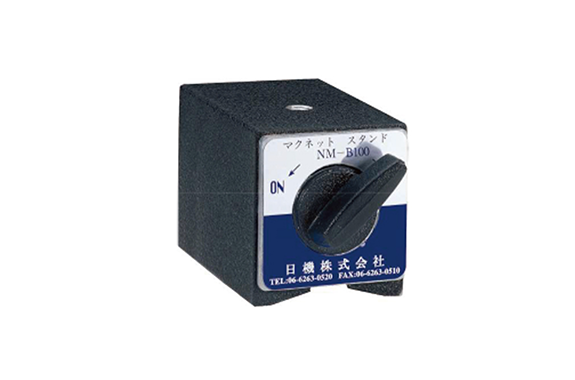

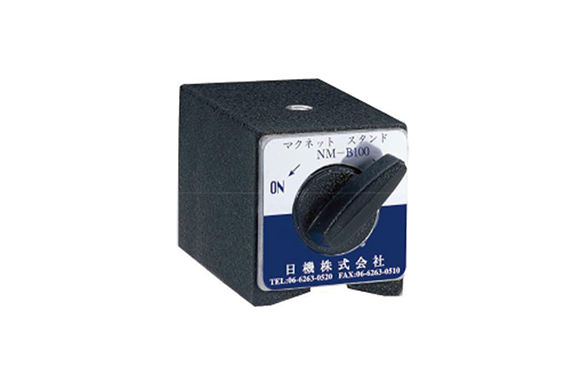

| Model | NM-B100 |

|---|---|

| size | 73 x 50 x 55 (H) mm |

| Screw Hole Dimensions | M8x1.25P |

| Maximum suction force | 1,000N |

| Adhesive surface | Bottom (V-shaped)/Rear |

| Model | NM-B130 |

|---|---|

| size | 117 x 50 x 55 (H) mm |

| Screw Hole Dimensions | M10x1.25P |

| Maximum suction force | 1,300N |

| Adhesive surface | Bottom (V-shaped)/Rear |

| Model | NM-B150G |

|---|---|

| size | 120 x 50 x 52 (H) mm |

| Screw Hole Dimensions | M8x1.25P |

| Maximum suction force | 1,500N |

| Adhesive surface | Bottom (concave)/rear |