Japan, Nikkin Flux

Nikkin Flux IA 500 Inclusion Analysis 500

Made in: Japan

Manufacturer: Nikkin Flux

Model: IA 500

Filtration Test

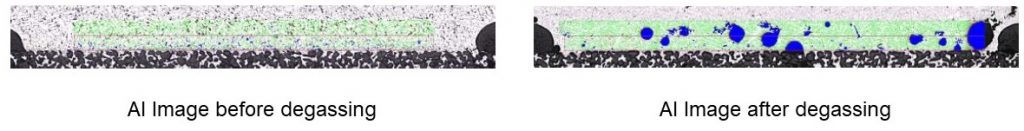

The IA500 allows a simple monitoring of quality. By doing filtration tests, you can measure the aluminum transit time per unit of filtration weight. The shorter the filtration time, the higher the probability of good quality aluminum.

Before degassing, the total inclusions are 0.32 mm2/kg with a filtration time of 1 35 sec. After degassing, the total inclusions are 0.05 mm2/kg with a filtration time of 65 sec.

As you can see from the analysis image, the filtration time is shorter when there are fewer impurities on the filter.

Filtration Test Procedure

About 3 kg of molten aluminum is filtered through the filter in IA500.

In a typical filtration tester, molten aluminum is poured into the device. In that case, the results are affected by oxidation during the pouring in the device and by the impact of dropping in the device.

The IA500, on the other hand, does not have the risk of such effects, as the aluminum is fed into the apparatus in its pre-melted state and melted in the apparatus. After filtration, impurities are deposited on the filter.

Consumables List

Below is the consumables list for IA500.

| NO. | Item Name and Replacement Timing | Picture | Size and Material |

| 1 | CERAMIC FILTER |  | ø120 x30t |

| Each filtration test | Complex of Silicic-acid calcium & Ceramic SiC filter | ||

| 2 | GASKET SMALL |  | ø120-1xø90x1t |

| Each filtration test | Carbon sheet processed goods | ||

| 3 | GASKET LARGE |  | ø190 x ø12O x 1t |

| After 10 filtration tests | Carbon sheet processed goods | ||

| 4 | CUSHION PAPER |  | ø120 x ø65 X 3t |

| After 3-5 filtration tests | Ceramic fiber paper processed goods which added and fabricated a little organic binders | ||

| 5 | CERAMICSHEATH (PROTECTION TUBE) |  | ø14 x 5OOL |

| In case of breakage | Product slip cast article made from silicon nitride | ||

| 6 | ALUMINIUM REMOVER |  | ø26x600L |

| Incase of breakage | Product slip cast article made from silicon nitride | ||

| 7 | KANTHALHEATER |  | ø350 x 250L (HAS2OO-25OG) |

| In case of breakage | Ceramic fiber Kanthal resistance heating alloy | ||

| 8 | IA LADLE |  | ø60 x 600L |

| In case of breakage | IRON or SUS | ||

| 9 | CERAMICCRUCIBLE |  | OD140-OD120x IDlOOx 300L |

| In case of breakage | Silicon nitride |

Other items of Nikkin Flux

Request the quotation for Nikkin Flux