- Home

- Products

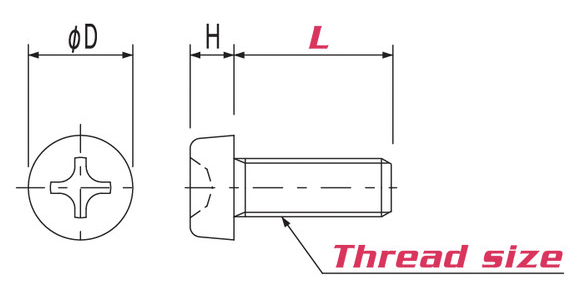

- Nippon Chemical Screw PEEK GF30/PH(Thread size-L) PEEK/GF30(+) inch pan head machine screw

Japan, Nippon Chemical Screw

Nippon Chemical Screw PEEK GF30/PH(Thread size-L) PEEK/GF30(+) inch pan head machine screw

Made in Japan

Manufacturer : Nippon Chemical Screw

Model :PEEK GF30/PH(Thread size-L)

Polyetheretherketone GF30(+) inch pan head machine screw.

| Continuous use temperature | 260°C/500°F |

| Combustion quality | UL94V-0 |

Property by material

| General properties | Test method | Test condition | Value |

| Density | ISO 1183 | 23°C 50%Rh | 1.5 g/cm³ |

| Water absorption rate | ISO 62 | 0.40% | |

| tensile elasticity | ISO 527 | 11000MPa | |

| Tensile strength | 165MPa | ||

| Tensile elongation | 2% | ||

| Bending strength | 250MPa | ||

| Bend elastic constant | 12.2Gpa | ||

| Charpy impact strength (with notch) | ISO 179/1 eA | 9C kJ/m² | |

| (1.8MPa) Deflection under load temperature | ISO 75 ASTM D648 | DRY | 323°C 614°F |

| UL94 Combustibleness (1.6mm) | IEC 60695 | V-O | |

| Volume resistivity | IEC 60093 | 1015 Ohm cm | |

| Permittivity (1MHz) | IEC 60250 | 3.3 | |

| Dielectric tangent (1MHz) | IEC 60250 | 0.004 |

Values in the table are for reference purpose only, and they are not guaranteed values.

| Thread size | #2-56 | #4-40 | #6-32 | #8-32 | #10-32 | 1/4-20 | |

| Thread Series | UNC | UNC | UNC | UNC | UNF | UNC | |

| D×H(inch) | 0.167×0.058 | 0.219×0.080 | 0.270×0.097 | 0.322×0.115 | 0.373×0.133 | 0.492×0.175 | |

| L(mm/inch) | 4.76 (3/16) | 100 | ─ | ─ | ─ | ─ | ─ |

| 6.35(1/4) | 100 | 100 | 100 | 100 | ─ | ─ | |

| 7.94(5/16) | 100 | 100 | 100 | 100 | ─ | ─ | |

| 9.53(3/8) | 100 | 100 | 100 | 100 | 100 | 100 | |

| 12.7(1/2) | ─ | 100 | 100 | 100 | 100 | 100 | |

| 15.87(5/8) | ─ | 100 | 100 | 100 | 100 | 100 | |

| 19.05(5/8) | ─ | 100 | 100 | 100 | 100 | 100 | |

| 22.22(7/8) | ─ | 100 | 100 | 100 | 100 | 100 | |

| 25.4(1″) | ─ | 100 | 100 | 100 | 100 | 100 | |

Sales unit Quantity

Torsional rupture torque

| Unit/Unit | 2-56 | 4-40 | 6n-32 | 8-32 | 10-32 | 1/4-20 |

| N・m | 0.11 | 0.23 | 0.44 | 0.79 | 1.17 | 2.5 |

| ft-lb | 0.081 | 0.17 | 0.325 | 0.583 | 0.863 | 1.844 |

Tensile rupture force

| Unit/Unit | 2-56 | 4-40 | 6-32 | 8-32 | 10-32 | 1/4-20 |

| N | 276 | 434 | 644 | 1017 | 1424 | 2160 |

| lbF | 62.04 | 97.56 | 144.77 | 228.62 | 320.12 | 485.57 |

- We use raw materials that are RoHS2 compliant.

- Black spots (sludge) may appear on the exterior.

- The remaining gate at the screw tip is less than 5% of the length (L).

- Please use in combination with a nut made of the same material as the thread pitch may shift during molding.

- If a nut is not used, the fit with the female thread should be 20 mm or less.

Features

- The values in the table are reference values and are not guaranteed values.

- Please use a torque driver and torque wrench for tightening. The recommended tightening torque is 50% of the breaking torque value under use.

- Heat resistance and chemical resistance vary depending on usage conditions, so be sure to test under usage conditions beforehand.

- There may be slight discoloration depending on the lot and various conditions.

- Inventory sizes, shapes, and manufacturers of materials used are subject to change without notice.