Japan, Nippon Daiya Valve

Nippon Daiya Valve Structure And Features Of Diaphragm Valves

Made in Japan

Manufacturer: Nippon Daiya Valve

Model: Structure And Features Of Diaphragm Valves

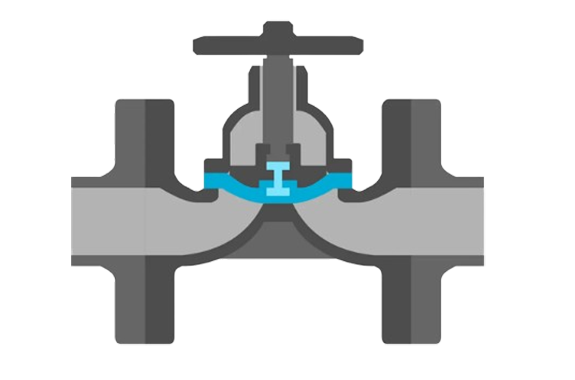

Basic structure and mechanism of diaphragm valves

Diaphragm valves are generally refer to valves with a structure that opens and closes the flow path with a flexible diaphragm such as rubber.

The basic structure of the valve consists of three units: the actuator, the diaphragm, and the body.

Features of diaphragm valves

①Excellent airtightness

This is a simple structure of three parts: the actuator, the diaphragm, and the body. Easy to disassembly and assembly.

④Excellent corrosion and chemical resistance

The simple body shape, suitable for lining processing.

⑤Environmentally friendly

Since the structure is simple, the number of parts is less than that of other valve types, and there is no waste in consumables.

Striving to reduce environmental impact by using lead-free chloroprene diaphragms and environmentally friendly paints, and by improving durability and reducing air consumption of actuator.

Related Products

-

Watanabe WPD-485 SPD for RS-485 – SPD (lightning arrester)

-

Tanitec Standard Hard Metal Saw Blade

-

Watanabe WSC-□□FS Acrylic Cover Type Non-contact Meter Relay

-

Okazaki Seiko SPSEE4GA Coated Solid Carbide Endmills (4 Flutes) (GO-RIKI MILL)

-

NOHMI BOSAI FPI012B-1L Series Dedicate Control Panel

-

TONE 3ATX-E Torx Socket for Impact Wrench