NIPPON FURNACE KOGYO KAISHA LTD.

Nippon Furnace HRS-UX Burner

Made In Japan

Manufacturer: NIPPON FURNACE KOGYO KAISHA LTD.

Model: HRS-UX

Burners & Combustion Equipment Business

Nippon Furnace began manufacturing and marketing combustion burners soon after World War II, initially under technical licensing agreements with world-famous burner manufacturers such as Bloom, Coen, Pillard, and Forney. However, the company later introduced high-quality, high-efficiency burners developed in its own R&D facilities, thus establishing its position in the combustion technology market. Moreover, starting in 1987, the company significantly increased its R&D efforts to develop a new Regenerative Combustion System, ‘HRS’ (High Cycle Regenerative Combustion System), in order to simultaneously respond to the growing global environmental consciousness and meet the demands of a rapidly expanding economy. As a result, HRS technology was adopted as the core technology in the High Performance Furnace Development Project, one of Japan’s national development initiatives. Furthermore, since 1999, the HRS burners have been widely adopted by numerous industrial furnaces as part of the National Field Test Project, where they have successfully demonstrated their excellence by reducing fuel consumption by over 30% compared to conventional burners, while also lowering NOx emissions. Consequently, NFK’s combustion burners and equipment, based on the most advanced combustion theories and technical data, are now receiving worldwide acclaim for their high efficiency and superior quality.

Burners & Combustion Equipment

industrial Furnaces equipped with Regenerative Burners(HRS Burners)

- HRS-DL Type Heat Treatment & Annealing Furnaces

- HRS-RT Type Heat Treatment Furnaces

- HRS-RT Type Aluminum Heat Treatment Furnaces

Burner for Fired Heater • Burner for Rotary Kiln

- Air Staged Low NOx Burner for Fired Heater of Refinery

- Fuel Staged Low NOx Burner for Fired Heater of Refinery

- Three (3) Fuel Burner for Rotary Kiln

Burners for Boiler • Economizer

- NNFK-LND Type Oil Fired Low NOx Burner

- NFK-LPCF Type Large Gas Fired Burner for Low Calorie Fuel

- NFK-ULN Type Gas Fired Low NOx Burner

- NFK-CGT Type Regenerator for Gas Turbine Exhaust

- NFK-ECG Type Anti-Corrosion Glass Economizer

Energy Saving Equipment & Maintenance for Boiler

- Heat Recovery & Energy Saving Equipment for Boiler

- Automatic Operation Control System & Remote Control System for Boiler

- Test Operation, Periodical Inspection & Maintenance Service of Boiler

Other Combustion & Energy Saving Equipment

- NFK-DEKA Air Pre-Heater

- A.I./S.I.(Air/Steam Enthalpy Intensifier)

- High Temperature/Pressure Indirect Hot Air Generator

- High Pressure/Enthalpy Intensified Combustor

- FCC/RFCC Air Heater

- Fired Heater

- Flame Detector

- COG Filter

Regenerative Burners (HRS Burners)

- HRS-DL Burner (Direct Firing Type)

- HRS-DF Burner (Direct Firing and Non-Oxidizing/Reducing Type)

- HRS-RT Burner (Radiant Tube Type)

- HRS-U1 Burner (Package Type Direct Firing Type)

- HRS-UX Burner (Continuous Fueling Direct Firing Type)

- HRS-CEM (Four Way Valve)

Regenerative Burners (HRS Burners)

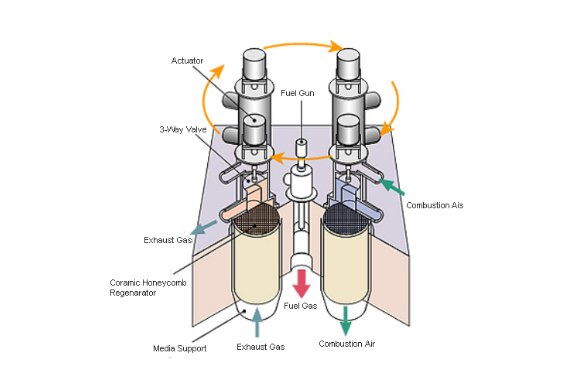

HRS (High Cycle Regenerative Combustion System) burners have achieved outstanding energy savings by means of ultra high pre-heated air combustion and high efficiency waste heat recovery systems. These were realized by use of NFK’s patented ceramic honeycomb regenerating media and CEM (Cross Exchange Mechanism), a four-way Switching Device. The HRS-ULN (ultra low NOx) burners, which are based on the latest fuel staging combustion theory, have consequently set a new standard in reducing NOx emissions. Furthermore, these burners represent a significant advancement in combustion technology, leading to both improved efficiency and environmental benefits.

HRS-UX Burner

(HRS Continuous Fueling/Direct Firing Type Burner)

This is a continuous fueling, direct-firing burner that features a built-in honeycomb regenerator and, moreover, incorporates ultra-high pre-heated air combustion technology. Consequently, it achieves both minimal pressure loss and low NOx emissions. In addition, the built-in block type honeycomb regenerator simplifies maintenance and servicing of the regenerator media. Furthermore, an additional fuel nozzle for off-gas combustion can be installed, offering increased versatility.

| Applications | Hydrogen generators, Indirect type reforming furnaces. |

|---|

Related Products

-

Nippon Furnace HRS-DL Roller Hearth Annealing Furnace

-

Nippon Furnace LPCF Large Gas Fired Burner For Low Calorie Fuel

-

Nippon Furnace HRS-RT Mesh-Belt Type Heat Treatment Furnace

-

Nippon Furnace Three Fuel Burner

-

Nippon Furnace HRS-DL Roller Hearth Type Heat Treatment Furnace

-

Nippon Furnace HRS-RT Batch Type Heat Treatment Furnace