Nippon Gear Co.

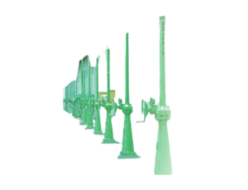

Nippon Gear L120 Series

Manufacturer: Nippon Gear Co., Ltd.

Model: L120 Series

Features

Robust housing

- Die-cast aluminum is used for small-sized standard housings, and cast iron is used for large-sized standard housings.

- The housing with standard specifications is the outdoor type (IP55), but we can also offer water-resistant and explosion-proof types to meet the needs of customers.

- The O-ring with a large wire diameter maintains high air-tightness over a long period of time.

Highly-durable gear train

- The worm gears and worms are made of aluminum bronze and chrome molybdenum steel, respectively. They enable the drive sleeve to have a long life of over 100,000 rotations.

- Optimum materials are used for the respective gears according to the loads, and extreme pressure grease is filled in the sealed gear case.

High-performance torque switch

- It has high-capacity silver contacts with long life.

- The operating point can be set within the entire torque range in both the opening and closing directions.

The valve is protected from overloads without fail.

High-precision geared limit switch

- All units are equipped with a four-position geared limit switch with a rated voltage of 600 V as standard.

- Four rotors have four contacts, respectively, to detect the four valve positions.

- The operating point can be set at any position within the entire stroke.

- The switch rotor is operated by the closed metallic intermittent gear lubricated with grease without fail. The preset position does not shift.

High-safety electric/manual mode switching operation

- All models are equipped with the declutch lever as standard. Switching the lever to manual mode position enables manual operation.

- When the motor rotates, the lever restores automatically, the electric operation mode is turned on, and the hand wheel does not rotate.

Equipped with the earth terminal/space heater as standard

- All models are equipped with the earth terminal for responding to highly humid and wet environments, as well as a space heater for stabilizing operation in low-temperature environments as standard. They can be used in a wide variety of fields.

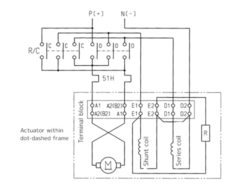

Enhanced control functions

- Integral control, consisting of various control devices, is applicable to the control station (control panel) and computerized control.

- It enables development into a centralized system that networks multiple actuators.

Specifications

| Unit size | L120-10 | L120-20 | L120-40 | L120-85 | L120-190 | L120-420 | L120-800 | L120-2000 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Mechanism and specifications | Allowable torque N・m | 140 | 270 | 540 | 1100 | 2500 | 5700 | 11000 | 27000 | |

| Allowable thrust kN | 44 | 88 | 130 | 200 | 330 | 620 | 1100 | 2200 | ||

| Maximum system diameter mm | Screw connection Drive 2 | ※32 | ※57 | ※66 | ※83 | ※88 | ※127 | ※127 | ※158 | |

| Key connection ※※Drive 1 | 24 (7×3 ) | 46 (14×3.8 ) | 53 (16×4.3 ) | 70 (20×4.9 ) | 73 (20×4.9 ) | 108 (28×6.4 ) | 180 (45×10.4 ) | 206 (50×11.4 ) | ||

| Output shaft rotation frequency min-1 | 60Hz | 12-192 | 12-192 | 12-192 | 12-192 | 12 18-96 120-192 | 12 18-72 84-168 | 12-36 84-192 | 12-30 36-60 | |

| 50Hz | 12-168 | 12-168 | 12-168 | 12-168 | 12-18 24-84 96-168 | 12-18 24-60 72-168 | 12-60 72-144 | 12-30 36-48 | ||

| Reduction rate of manual type | Standard | 1:1 | 1:1 | 1:1 | ※※※ | 40:1 24:1 9:1 | 39:1 28:1 11:1 | 34:1 13:1 | 270:1 164:1 | |

| Option | 4.2:1 | 5.7:1 | 12:1 | ー | 115:1 69:1 26:1 | 236:1 170:1 67:1 | 202:1 79:1 | 772:1 468:1 | ||

| Attachable actuator | BA(Allowable thrust: 26 – 1,200 kN, for multi-turn-type valve) HB(Allowable torque: 0.83 – 200 kN·m, for part-turn-type valve) H(Allowable torque: 390 – 1,100 kN·m, for part-turn-type valve) | |||||||||

| Electric and control specifications | Motor | Power supply | AC 200V/400V/50Hz、200V/440V/60Hz(Compatible to 600 V AC and lower) | |||||||

| Starting torque | 500% | |||||||||

| Insulation class | Class F | |||||||||

| Rated time | 15 minutes | |||||||||

| Thermostat | 15 minutes | |||||||||

| Space heater | Supplied | |||||||||

| Thermal protector | Option | |||||||||

| Motor starter | Option | |||||||||

| Trans | ||||||||||

| Push-button switch | ||||||||||

| Indication light | ||||||||||

| Selector switch | ||||||||||

| Position transmitter | ||||||||||

| Modulating control | ||||||||||

| Protection type | Protection structure | IP55,67、NEMA,I,Ⅱ,Ⅳ,Ⅵ | ||||||||

| Explosion-proof | JIS Exdll BT4 FM Class 1 Group B,C,D Division 1,2 FM Class 2 Group E,F,G Division 1,2 CSA Class 1 Group B Division 2 CSA Class 1 Group C,D Division 1,2 CSA Class 2 Group E,G Division 1,2 Cenelec Group 2a,2b T4(BS 5501 PART 5 ) | |||||||||

*Represents the screw connection with a thrust base.

**Represents the key connection and the value in parenthesis is the maximum keyway dimension.

***Same as the reduction ratio of the unit.

The L120-85 and higher models are manufactured by Flowserve Corporation in the United States.