Japan, Nippon Seimitsu

Nippon Seimitsu Bag-in Bug-out Dust Collector

Product Made in Japan

Manufacturer: Nippon Seimitsu Co., Ltd.

Model: Bag-in Bug-out

Non-contact dust collector “Bag-in Bug-out Dust Collector”

Ensure work safety with scatter prevention mechanism.

Dust does not scatter during filter replacement or dust discharge.

This dust collector ensures work safety and provides a secure environment with its powder scattering prevention mechanism. You can use a dedicated filter and replacement vinyl pack to replace the filter without direct contact with the powder. A clean dust pack is used for the dust discharge section under the device’s hopper, enabling you to seal and dispose of discharged powder without touching it. This prevents dust from scattering and ensures no contact. Our standard lineup includes models with 2 to 12 filters, but we can also accommodate various requests with custom specifications.

- Prevents contamination in food factories.

- For collecting dust from highly active active ingredients at pharmaceutical and active ingredient factories.

- To prevent environmental pollution at each plant.

- To maintain cleanliness in clean rooms.

- We can offer top fan type and separate blower type. We will select the optimal collector based on the required air volume and static pressure.

Features

- The scatter prevention mechanism ensures work safety and provides a safe and secure collection device.

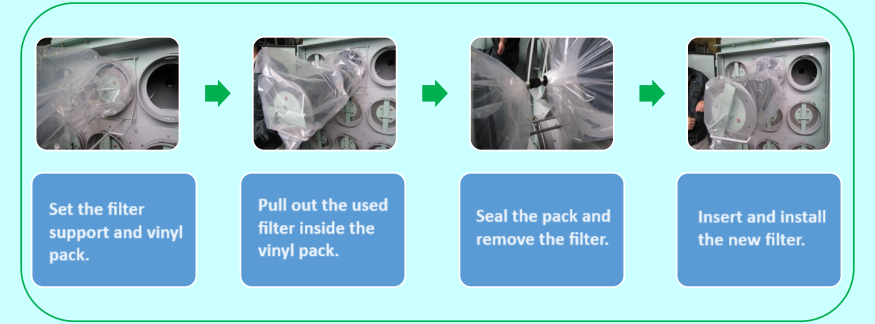

- It uses a special filter replacement seal pack, allowing filter replacement without direct contact with dust.

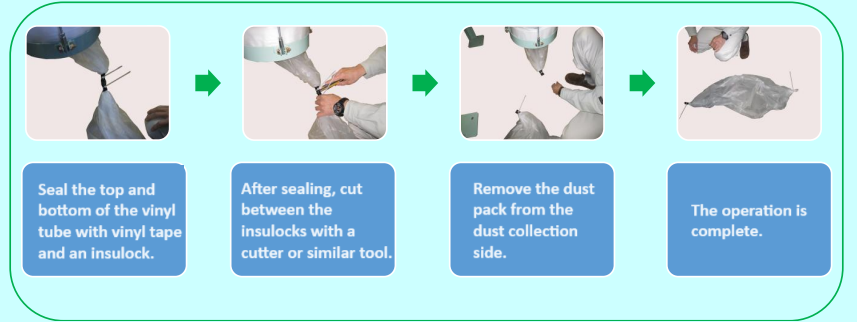

- The dust discharge section under the hopper is equipped with a clean dust pack.

- Sealing and disposing of the special pack prevents dust from scattering.

Filter Replacement Methods and Procedures

Dust Discharge Methods and Procedures

Device Specifications And Approximate Dimensions

| Type | 12m² Type | 25m² Type | 38m² Type | 50m² Type | 57m² Type | 76m² Type |

|---|---|---|---|---|---|---|

| Filter Area | 12.6 m² | 25.2 m² | 37.8 m² | 50.4 m² | 56.7 m² | 75.6 m² |

| Filter Material | Polyester (Standard) | |||||

| Number of Filters | 2 | 4 | 6 | 8 | 9 | 12 |

| Filtration Speed | 1.5 m/min (MAX) | |||||

| Cleaning Method | Pulse Jet Method | |||||

| Cleaning Air Pressure | 0.4 – 0.5 MPa | |||||

| Cleaning Air Consumption | 30 NL/min | 40 NL/min | 60 NL/min | 90 NL/min | 90 NL/min | 120 NL/min |

| Main Body Durability Pressure | -4.5 KPa | |||||

| Power Source | 1 phase, 200V | |||||

| Suction Inlet Diameter | φ200 | φ250 | φ300 | φ400 | φ400 | 400×400 |

| Discharge Outlet Dimensions | φ200 | φ300 | φ350 | 300×550 | 300×550 | 300×650 |

| Hopper Capacity | Approx. 150 L | Approx. 240 L | Approx. 270 L | Approx. 480 L | Approx. 480 L | Approx. 850 L |

| Dimension | 12m² Type | 25m² Type | 38m² Type | 50m² Type | 57m² Type | 76m² Type |

|---|---|---|---|---|---|---|

| A | 1060 | |||||

| B | 900 | 1070 | 1070 | 1380 | 1380 | 1780 |

| C | 3750 | 3975 | 4440 | 4840 | 4840 | 5355 |

| D | 1250 | 1250 | 1250 | 1250 | 1250 | 1250 |

| E | 1000 | 1100 | 1100 | 1300 | 1300 | 1700 |

| F | 1250 | 1350 | 1350 | 1660 | 1660 | 2060 |

| G | 800 | |||||

Due to the quality of performance products, specifications may change without notice.

Please understand. Do not collect dust with high explosive risk such as aluminum, magnesium, or zinc.

Consult us when using in explosive atmospheres or high temperature environments.