Nippon Yakin Kogyo Co., Ltd

Nippon Yakin Kogyo NAS254N Corrosion Resistant Alloys

Manufacturer: Nippon Yakin Kogyo Co., Ltd

Model: NAS254N

NAS254N (UNS S32053)

High Corrosion Resistant Super Stainless Steel

NAS254N (SUS836L, UNS S32053) is a high corrosion resistance austenitic stainless steel with a high nickel, high chromium, high molybdenum alloy design, and provides excellent corrosion resistance in severe corrosion environments such as high temperature seawater. Depending on the environment, this stainless steel offers high economy combined with corrosion resistance comparable to that of Nickel alloy and pure titanium. Nippon Yakin supplies this product in plate, sheet, and strip form.

| Chemical Composition | 23Cr-25Ni-5.5Mo-0.2N | ||

| Product shape |  Coil |  Sheet |

|

| Workability | Hot and cold workability similar to standard austenitic stainless steels like Type 304, 316; requires care due to high strength | ||

| Weldability | Various methods applicable; shielded metal arc welding, TIG welding, and plasma welding suitable. Alloy 276 consumables recommended. | ||

| Machinability | Machining is difficult but easier than Ni-based alloys; use of ultra-hard tool and slow feed rate recommended | ||

| Heat Treatment | Solution annealing at 1080-1180°C, quenching in water or rapid cooling | ||

| Pickling | Mixture of nitric acid and hydrofluoric acid; material should be immersed in alkaline solution before pickling, shot blasting effective | ||

| Applications | Food manufacturing, Salt manufacturing, Pharmaceutical plants, Chemical plants, Marine structures, Heat exchangers | ||

Steel Grade/Standard

| Nippon Yakin Grade | JIS G 4304/4305 | ASTM A240 | EN |

|---|---|---|---|

| NAS254N | SUS836L | UNS S32053 | — |

Chemical Composition

| Specification | C | Si | Mn | P | S | Ni | Cr | Mo | N |

|---|---|---|---|---|---|---|---|---|---|

| SUS836L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 24.00 – 26.00 | 19.00 – 24.00 | 5.00 – 7.00 | ≤0.25 |

| UNS S32053 | ≤0.030 | ≤1.00 | ≤1.00 | ≤0.030 | ≤0.010 | 24.00 – 26.00 | 22.00 – 24.00 | 5.00 – 6.00 | 0.17 – 0.22 |

Physical Properties

| Density [g/cm³] | 8.06 |

|---|---|

| Specific heat [J/kg·K] | 457 |

| Electrical resistivity [µΩ·cm] | 94.7 |

| Thermal conductivity [W/m·K] | 11.9 |

| Average coefficient of thermal expansion [10⁻⁶/°C] | 30-100°C: 14.6 30-200°C: 15.2 30-300°C: 15.5 30-400°C: 15.8 |

| Young’s modulus [MPa] | 19.7 × 10⁴ |

| Magnetism | None |

| Melting range [°C] | 1330 – 1390 |

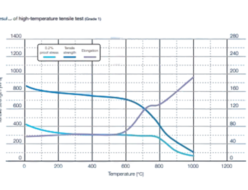

Mechanical Properties

Mechanical Properties at Room Temperature

| Specification | 0.2% proof stress [MPa] | Tensile strength [MPa] | Elongation [%] | Hardness [HBW] | Hardness [HRBW] | Hardness [HV] |

|---|---|---|---|---|---|---|

| SUS836L | ≥275 | ≥640 | ≥40 | ≤217 | ≤96 | ≤230 |

| UNS S32053 | ≥295 | ≥640 | ≥40 | ≤217 | ≤96 | — |

| Cold-rolled sheet 2mm | 385 | 760 | 46 | — | — | — |

| Hot-rolled plate 16mm | 336 | 725 | 56 | 172 | — | — |

NAS254N is a high Cr, high Mo stainless steel which provides excellent pitting corrosion resistance and crevice corrosion resistance in high Cl environments. As a high Ni steel, it also offers excellent stress corrosion cracking resistance.

Pitting Corrosion Resistance

Alloy | ASTM G48 Method A | ASTM G48 Method C | Critical pitting corrosion temperature CPT (°C) |

22°C | 50°C | ||

NAS255 | ○ | × | 50 |

| NAS329J3L | ○ | × | 50 |

| NAS64 | ○ | ○ | 55 |

ASTM G48 Method A (○: No pitting corrosion, ×: Pitting corrosion)

Test solution: 6%FeCl3

Test temperature: 22°C, 50°C (Recommended temperature in this test)

Test time: 72h

Crevice Corrosion Resistance

Alloy | ASTM G48 Method D |

Critical crevice corrosion temperature CCT (°C) | |

NAS255 | 10 |

| NAS329J3L | 25 |

| NAS64 | 30 |

| NAS254N | 45 |

* Test conditions: ASTM G48 Method D

* Test solution: 6%FeCl3 + 1%HCl

* Test time: 72h

Stress Corrosion Cracking Resistance

| Alloy | MgCl₂ concentration (boiling point °C are in brackets) | |||||||

| 45% (155°C) | 42% (143°C) | 40% (138°C) | 38% (134°C) | 35% (126°C) | 30% (115°C) | 25% (110°C) | 20% (108°C) | |

| NAS255 | × | × | × | × | ○ | ○ | ○ | ○ |

| NAS329J3L | × | × | × | × | × | ○ | ○ | ○ |

| NAS64 | × | × | ○ | ○ | ○ | ○ | ○ | ○ |

| NAS254N | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Test conditions: Immersion in boiling MgCl₂ solution

They use a U-bend test specimen.

○: No stress corrosion cracking

×: Stress corrosion cracking

Acid Resistance

Corrosion rate in sulfuric acid at 80°C (mm/y)

| Alloy | 5% | 10% | 20% | 40% | 60% | 80% |

|---|---|---|---|---|---|---|

| NAS255 | <0.01 | <0.01 | 0.78 | 2.95 | 0.48 | 5.01 |

| NAS329J3L | 0.01 | 0.17 | 4.65 | 365.9 | 145.6 | 106.4 |

| NAS64 | <0.01 | 0.02 | 1.07 | 191.9 | 1054 | 60.72 |

| NAS254N | 0.02 | 0.05 | 1.02 | 2.11 | 2.16 | 7.76 |

Test time: 24h

Corrosion rate in hydrochloric acid at 80°C (mm/y)

| Alloy | 0.1% | 1% | 2% | 3% |

|---|---|---|---|---|

| NAS255 | <0.01 | 0.01 | 2.70 | 3.72 |

| NAS329J3L | 0.02 | 0.03 | 31.10 | 60.62 |

| NAS64 | 0.01 | 0.12 | 12.94 | 30.51 |

| NAS254N | 0.01 | 0.02 | 0.01 | 9.14 |

Test time: 24h

Reference

| Alloy | JIS | UNS No. | Chemical composition |

|---|---|---|---|

| NAS255 | SUS890L | N08904 | 20Cr-24Ni-4.3Mo-1.5Cu |

| NAS329J3L | SUS329J3L | S32205 | 22Cr-5.3Ni-3.0Mo-0.16N |

| NAS64 | SUS329J4L | S32605 | 25Cr-6.5Ni-3.3Mo-0.17N |

| NAS254N | SUS836L | S32053 | 23Cr-25Ni-5.5Mo-0.2N |

Workability

The hot and cold workability of NAS254N is basically the same as that of standard austenitic stainless steels such as Type 304, Type 316, etc. The fact that this is a high-strength material requires consideration in both cold and hot working.

Weldability

Various welding methods are applicable in the same manner as with the standard austenitic stainless steels, including shielded metal arc welding, TIG welding, and plasma welding. Alloy 276 welding consumable should be used.

Machinability

As a feature of high Ni stainless steels, although machining is difficult in comparison with the standard austenitic stainless steels, it is easier than with Ni-based alloys. A ultrahard tool should be used in machining if at all possible. It is also advisable to use a slower feed rate and deeper cutting depth.

Heat Treatment

Solution annealing of NAS254N should be performed at the temperature range from 1130 to 1180°C followed by being quenched in water or rapidly cooled by other means. (Conditions provided in ASTM A480/A480M)

Pickling

A mixture of nitric acid and hydrofluoric acid is used in pickling. However, due to the high corrosion resistance of NAS254N, scale is somewhat difficult to remove in comparison with Type 304. Therefore, the material should be immersed in an alkaline solution before pickling or, if possible, shot blasting is extremely effective.

Applications

Food manufacturing plants, Salt manufacturing plants, Pharmaceutical plants, Chemical plants, Flue gas desulfurization plants, Marine structures, Marine equipment, related equipment, Heat exchangers, Various types of bleaching equipment.

Related Products

-

Nippon Yakin Kogyo NASNi201 Corrosion Resistant Pure Nickel

-

Nippon Yakin Kogyo NAS354N Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS8R10 Neutron Absorbing Stainless Steel

-

Nippon Yakin Kogyo NASPB SoftMagnetic Alloys

-

Nippon Yakin Kogyo NAS625 Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NASPC Soft Magnetic Alloys