Nippon Yakin Kogyo Co., Ltd

Nippon Yakin Kogyo NAS329J3L Corrosion Resistant Alloys

Manufacturer: Nippon Yakin Kogyo Co., Ltd

Model: NAS329J3L

NAS 329J3L (UNS S32205, S31803)

NAS High Corrosion Resistant Duplex Stainless Steel

NAS 329J3L (SUS 329J3L, UNS S32205, S31803) is an Austenitic-ferritic stainless steel, which has superior corrosion resistance and high strength This steel provides better localized corrosion resistance than Type 316L and 317L, and industries such as chemical plants, seawater desalination plants, and seawater pumps apply it widely. Nippon Yakin supplies this product in plate, sheet, and strip form.

| Chemical Composition | 22Cr-5.3Ni-3.2Mo-0.1N | ||

| Product Shape |

|  Sheet Sheet |

|

| Workability | High temperature strength is similar to Type 430 in the range of 950-1150°C. However, the steel shows a rapid increase in strength below 900°C. Cold working requires care because the higher proof stress and lower elongation of this steel, compared to Type 304, make the process more challenging. | ||

| Weldability | You can apply various welding methods, such as shielded metal arc welding, TIG welding, and plasma welding, in the same way as with standard austenitic stainless steels. It is recommended to use welding electrodes for UNS S32205. Preheating and post-heating are not necessary. The interpass temperature should not exceed 100°C to prevent formation of intermetallic compounds. | ||

| Heat Treatment | Solution annealing of NAS329J3L should be performed at 1040°C and higher followed by being quenched in water or rapidly cooled by other means. (Conditions provided in ASTM A480/A480M) | ||

| Pickling | You should use a mixture of nitric acid and hydrofluoric acid for pickling. Since descaling is more difficult compared to Type 304, it is recommended to perform alkaline immersion before pickling or to use shot blasting. | ||

| Applications | Chemical Plant, Chemical Tanker, Seawater desalination plant, Seawater pump, Thermal power plant flue gas desulfurization plants, Pulp and paper plants, Bridge. | ||

Steel Grade/Standard

| Nippon Yakin Grade | JIS G4304/4305 | ASTM A240 | EN 10088-2/10028-7 |

|---|---|---|---|

| NAS 329J3L | SUS 329J3L | UNS S32205/S31803 | 1.4462 |

Chemical Composition

| C | Si | Mn | P | S | Ni | Cr | Mo | N | |

|---|---|---|---|---|---|---|---|---|---|

| Specification (SUS 329J3L) | ≦0.030 | ≦1.00 | ≦2.00 | ≦0.040 | ≦0.030 | 4.50 ~ 6.50 | 21.00 ~ 24.00 | 2.50 ~ 3.50 | 0.08 ~ 0.20 |

| Specification (UNS S32205) | ≦0.030 | ≦1.00 | ≦2.00 | ≦0.030 | ≦0.020 | 4.5 ~ 6.5 | 22.00 ~ 23.00 | 3.0 ~ 3.5 | 0.14 ~ 0.20 |

| Specification (UNS S31803) | ≦0.030 | ≦1.00 | ≦2.00 | ≦0.030 | ≦0.020 | 4.5 ~ 6.5 | 21.0 ~ 23.0 | 2.5 ~ 3.5 | 0.08 ~ 0.20 |

Physical Properties

| Density [g/cm³] | 7.80 |

|---|---|

| Specific heat [J/kg·K] | 460 |

| Electrical resistivity [μΩ·cm] | 87.0 |

| Thermal conductivity [W/m·K] | 13.9 |

| Average coefficient of thermal expansion [10⁻⁶/°C] | 20 ~ 100°C: 12.7 20 ~ 200°C: 13.1 20 ~ 300°C: 13.5 20 ~ 400°C: 13.8 |

| Young’s modulus [MPa] | 19.5 × 10⁴ |

| Magnetism | Y (magnetizable) |

| Melting range [°C] | 1420 ~ 1465 |

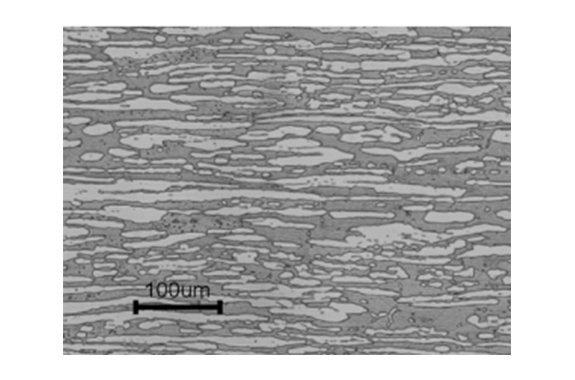

Microstructure

A cross sectional microstructure of 16mm thick plate

A cross sectional microstructure of 16mm thick plateMechanical Properties

Mechanical Properties at Room Temperature

| Specification | 0.2% proof stress [MPa] | Tensile strength [MPa] | Elongation [%] | Hardness [HV] | Hardness [HB] |

|---|---|---|---|---|---|

| Specification (SUS 329J3L) | ≥450 | ≥620 | ≥18 | ≤320 | ≤302 |

| Specification (UNS S32205) | ≥450 | ≥655 | ≥25 | — | ≤293 |

| Specification (UNS S31803) | ≥450 | ≥620 | ≥25 | — | ≤293 |

| Example: Hot-rolled plate 16mm | 563 | 780 | 35 | — | 222 |

| Example: Cold-rolled sheet 2mm | 630 | 828 | 28 | 253 | — |

Corrosion Resistance

Pitting Corrosion Resistance

| Alloy | ASTM G48 Method A | ASTM G48 Method C | |

|---|---|---|---|

| 22°C | 50°C | Critical pitting corrosion temperature CPT (°C) | |

| SUS 304 | × | × | 10 |

| SUS 316L | × | × | 15 |

| NAS 329J3L | ○ | × | 50 |

Test conditions

ASTM G48 Method A (○: No pitting corrosion, ×: Pitting corrosion)

- Test solution: 6% FeCl₃

Test temperature: 22°C, 50°C (Recommended temperature in this test)

Test time: 72h

ASTM G48 Method C

- Test solution: 6% FeCl₃ + 1% HCl

Test time: 72h

Crevice Corrosion Resistance

| Alloy | ASTM G48 Method D | |

|---|---|---|

| Critical crevice corrosion temperature CCT (°C) | SUS 304 | <10 |

| SUS 316L | <10 | |

| NAS 329J3L | 25 |

Test solution: 6% FeCl₃ + 1% HCl

Test time: 72h

Stress Corrosion Cracking Resistance

| Alloy | 45% (155°C) | 42% (143°C) | 40% (138°C) | 38% (134°C) | 35% (126°C) | 30% (115°C) | 25% (110°C) | 20% (108°C) |

|---|---|---|---|---|---|---|---|---|

| SUS 304 | × | × | × | × | × | × | × | ○ |

| SUS 316L | × | × | × | × | × | × | × | × |

| NAS 329J3L | × | × | × | × | × | × | ○ | ○ |

Test conditions: Immersion in boiling MgCl₂ solution

Test time: 300h

U-bend test specimen is used

○: No stress corrosion cracking ×: Stress corrosion cracking

Acid Resistance

Corrosion rate in sulfuric acid at 80°C (mm/y)

| Alloy | 5% | 10% | 20% | 40% | 60% | 80% |

|---|---|---|---|---|---|---|

| SUS 304 | 14.59 | 195.2 | 1347 | 231.8 | 151.4 | 137.4 |

| SUS 316L | 0.67 | 1.89 | 46.94 | 704.5 | 33.74 | 106.4 |

| NAS 329J3L | 0.01 | 0.17 | 4.65 | 365.9 | 1456 | 106.4 |

Test time: 24h

Corrosion rate in hydrochloric acid at 80°C (mm/y)

| Alloy | 0.1% | 1% | 2% | 3% |

|---|---|---|---|---|

| SUS 304 | 2.42 | 2.11 | 8.13 | 15.12 |

| SUS 316L | 0.02 | 2.73 | 7.65 | 14.68 |

| NAS 329J3L | 0.03 | 3.11 | 10.66 | 23.74 |

Test time: 24h

| Alloy | Nippon Yakin | JIS | UNS No. | Chemical composition |

|---|---|---|---|---|

| SUS 304 | S30400 | 18Cr-8Ni | ||

| SUS 316L | S31603 | 170Cr-12Ni-2Mo | ||

| NAS 329J3L | S32205 | 22Cr-5.3Ni-3.2Mo-0.16N |

Workability

High temperature strength is similar to Type 430 in the range of 950-1150°C. However, the steel shows a rapid increase in strength below 900°C. Regarding cold workability, care is required as proof stress is high and elongation is low in comparison with Type 304.

Weldability

Various welding methods are applicable in the same manner as with standard austenitic stainless steels, including shielded metal arc welding, TIG welding, and plasma welding. The use of welding electrodes for UNS S32205 is recommended. Preheating and post-heating are not necessary. The interpass temperature should be no more than 100°C to prevent the formation of intermetallic compounds.

Heat Treatment

Solution annealing of NAS 329J3L should be performed at 1040°C and higher followed by being quenched in water or rapidly cooled by other means. (Conditions provided in ASTM A480/A480M)

Pickling

A mixture of nitric acid and fluoridic acid is used in pickling. Descaling is somewhat difficult in comparison with Type 304, so alkaline immersion before pickling, or shot blasting, is recommended.

Applications

- Chemical Plant, Chemical Tanker

- Seawater desalination plant, Seawater pump

- Thermal power plant flue gas desulfurization plants

- Pulp and paper plants

- Bridge

Certification

It is possible to manufacture UNS S32205/S31803 in accordance with the NORSOK standard. The thickness is up to 50mm.

- NORSOK M-650

- NORSOK M-630 MDS D45

Related Products

-

Nippon Yakin Kogyo NAS631 High Strength Stainless Steels

-

Nippon Yakin Kogyo NASH880 Heat Resistant Alloys

-

Nippon Yakin Kogyo NAS335X Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS36LG Controlled Expansion Alloys

-

Nippon Yakin Kogyo NAS75N Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS255NM Corrosion Resistant Alloys

Coil

Coil Plate

Plate