Nippon Yakin Kogyo Co., Ltd

Nippon Yakin Kogyo NAS355N Corrosion Resistant Alloys

Manufacturer: Nippon Yakin Kogyo Co., Ltd

Model: NAS355N

NAS355N

High Corrosion Resistant Nickel Alloy

NAS355N is a high corrosion resistant nickel alloy, providing corrosion resistance in high-concentration chloride ion or sulfuric acid environments and in extremely severe corrosive environments where both high-concentration chloride ions and sulfuric acid exist. They significantly reduced the nickel content of this alloy compared to conventional high corrosion resistant nickel alloys, achieving a good balance between cost and corrosion resistance performance. Nippon Yakin supplies this product in plate, sheet, and strip form.

| Chemical Composition | 23Cr-35Ni-7.5Mo-3Cu-0.2N | ||

| Product shape |  Coil Coil |  Sheet Sheet |  Plate Plate |

| Workability | The hot and cold workability of NAS355N is basically the same as that of standard austenitic stainless steels such as Type 304, Type 316.However, you must consider that this material has high strength in both cold and hot working processes. | ||

| Weldability | Various welding methods are applicable in the same manner as with the standard austenitic stainless steels, including shielded metal arc welding, TIG welding, and plasma welding.You should use Alloy 276 welding consumable. | ||

| Heat Treatment | Solution heat treatment is performed at 1030°C~1180°C using water cooling. | ||

| Pickling | They use a mixture of nitric acid and hydrofluoric acid in pickling. However, due to the high corrosion resistance of NAS355N, scale is somewhat difficult to remove in comparison with Type 304. Therefore, you should immerse the material in an alkaline solution before pickling, or, if possible, use shot blasting, which is extremely effective. | ||

| Applications | Chemical plants, Flue gas desulfurization plants, Heat exchangers, Environment-related equipment. | ||

Grade/Standard

| Nippon Yakin Grade | JIS | ASTM | EN |

|---|---|---|---|

| NAS355N | — | — | — |

Chemical Composition

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| Specification (NAS355N) | ≦0.030 | ≦1.00 | ≦1.00 | ≦0.020 | ≦0.005 | 35.00 – 36.00 | 22.00 – 24.00 | 7.00 – 8.00 | 3.00 – 4.00 | 0.19 – 0.24 |

Physical Properties

| Density [g/cm³] | 8.16 |

|---|---|

| Specific heat [J/kg·K] | 431 |

| Electrical resistivity [µΩ·cm] | 107.4 |

| Thermal conductivity [W/m·K] | 9.99 |

| Average coefficient of thermal expansion [10⁻⁶/°C] | 30 – 100°C: 13.7 30 – 200°C: 14.2 30 – 300°C: 14.5 30 – 400°C: 14.9 |

| Young’s modulus [MPa] | 18.7 × 10⁴ |

| Magnetism | None |

| Melting range [°C] | 1320 – 1366 |

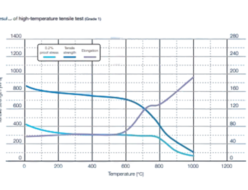

Mechanical Properties at Room Temperature

| Specification | 0.2% proof stress [N/mm²] | Tensile strength [N/mm²] | Elongation [%] | Hardness [HV] | Hardness [HBW] | Hardness [HRBW] |

|---|---|---|---|---|---|---|

| Specification (NAS355N) | ≥295 | ≥640 | ≥35 | ≥230 | ≥217 | ≤96 |

| Example: Cold-rolled sheet 2mm | 422 | 807 | 49 | 196 | — | 91 |

Pitting Corrosion Resistance

| Alloy | ASTM G48 Method A | ASTM G48 Method C | |

| 22°C | 50°C | Critical pitting corrosion temperature (CPT) [°C] | |

| NAS335X | ○ | × | 30 |

| NAS64 | ○ | ○ | 55 |

| NAS185N | ○ | ○ | 70 |

| NAS254N | ○ | ○ | 80 |

| NAS354N | ○ | ○ | 103 |

| NAS355N | ○ | ○ | 100 |

ASTM G48 Method A (○: No pitting corrosion, ×: Pitting corrosion)

Test solution: 6%FeCl₃

Test temperature: 22°C, 50°C (Recommended temperature in this test)

Test time: 72h

Crevice Corrosion Resistance

| Alloy | Critical crevice corrosion temperature (CCT) [°C] |

|---|---|

| NAS335X | <0 |

| NAS64 | 30 |

| NAS185N | 40 |

| NAS254N | 45 |

| NAS354N | 50 |

| NAS355N | 55 |

Test conditions: ASTM G48 Method D

Test solution: 6%FeCl₃ + 1%HCl

Test time: 72h

Stress Corrosion Cracking Resistance

| Alloy | 45% (155°C) | 42% (143°C) | 40% (138°C) | 38% (134°C) | 35% (126°C) | 30% (115°C) | 25% (110°C) | 20% (108°C) |

| NAS335X | × | × | × | × | ○ | ○ | ○ | ○ |

| NAS64 | × | × | × | × | ○ | ○ | ○ | ○ |

| NAS185N | × | × | × | ○ | ○ | ○ | ○ | ○ |

| NAS254N | × | × | ○ | ○ | ○ | ○ | ○ | |

| NAS354N | × | × | × | ○ | ○ | ○ | ○ | ○ |

| NAS355N | × | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Test conditions: Immersion in boiling MgCl₂ solution

Test time: 300h

They use a U-bend test specimen.

○: No stress corrosion cracking ×: Stress corrosion cracking

Acid Resistance

Corrosion rate in sulfuric acid at 80°C (mm/y)

| Alloy | 5% | 10% | 20% | 40% | 60% | 80% |

|---|---|---|---|---|---|---|

| NAS335X | 0.01 | 0.02 | 0.31 | 0.12 | 0.60 | 2.15 |

| NAS64 | <0.01 | 0.02 | 1.07 | 191.9 | 1054 | 60.72 |

| NAS185N | 0.04 | 1.32 | 2.89 | 3.20 | 4.78 | — |

| NAS254N | 0.05 | 1.02 | 2.11 | 2.16 | 7.76 | — |

| NAS354N | 0.01 | 0.03 | 0.23 | 0.06 | 3.02 | 4.99 |

| NAS355N | <0.01 | <0.01 | 0.31 | — | 1.12 | — |

Test time: 24h

Corrosion rate in hydrochloric acid at 80°C (mm/y)

| Alloy | 0.1% | 1% | 2% | 3% |

|---|---|---|---|---|

| NAS64 | 0.01 | 0.12 | 12.94 | 30.51 |

| NAS185N | 0.01 | 0.02 | 4.20 | 7.21 |

| NAS254N | 0.01 | 0.02 | 0.01 | 9.14 |

| NAS354N | <0.01 | 0.03 | 0.02 | 7.35 |

| NAS355N | — | <0.01 | — | 3.65 |

Test time: 24h

| Alloy | JIS | UNS No. | Chemical composition |

|---|---|---|---|

| NAS335X | NCF020 | N08020 | 20Cr-33Ni-2.5Mo-3Cu-0.4Nb |

| NAS64 | SUS329J4L | S32506 | 25Cr-6.5Ni-3.3Mo-0.17N |

| NAS185N | SUS312L | S31254 | 20Cr-18Ni-6Mo-0.8Cu-0.2N |

| NAS354N | NCF354 | N08354 | 23Cr-35Ni-7.5Mo-0.2N |

| NAS355N | — | — | 23Cr-35Ni-5Mo-3Cu-0.2N |

Workability

The hot and cold workability of NAS355N is basically the same as that of standard austenitic stainless steels such as Type 304, Type 316, etc. However, you must consider the high strength of this material in both cold and hot working processes.

Weldability

Various welding methods are applicable in the same manner as with standard austenitic stainless steels, including shielded metal arc welding, TIG welding, and plasma welding. Alloy 276 welding consumable should be used.

Heat Treatment

Solution heat treatment is performed at 1030°C~1180°C using water cooling.

Pickling

A mixture of nitric acid and hydrofluoric acid is used in pickling. However, due to the high corrosion resistance of NAS355N, scale is somewhat difficult to remove in comparison with Type 304. Therefore, the material should be immersed in an alkaline solution before pickling, or if possible, shot blasting is extremely effective.

Applications

Chemical plants, Flue gas desulfurization plants, Heat exchangers, Environment-related equipment.

Related Products

-

Nippon Yakin Kogyo NAS36LG Controlled Expansion Alloys

-

Nippon Yakin Kogyo NAS329J3L Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS255NM Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS800 Heat Resistant Alloys

-

Nippon Yakin Kogyo NAS74N Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS625 Corrosion Resistant Alloys