Nippon Yakin Kogyo Co., Ltd

Nippon Yakin Kogyo NAS601 Heat Resistant Alloys

Manufacturer: Nippon Yakin Kogyo Co., Ltd

Model : NAS601

NAS601 (UNS N06601)

Heat-Resistant Nickel Alloy

NAS601 (NCF601, UNS N06601) is a nickel-chromium alloy with an addition of aluminum that provides high mechanical properties at elevated temperatures and superior resistance to oxidation, carburization, and sulfurization. It excels in descaling resistance during cyclic oxidation with high-temperature variations, making it ideal for use in various parts of heat treatment furnaces, diesel vehicle glow plugs, and similar applications. Nippon Yakin supplies this product in plate, sheet, and strip forms.

| Chemical Composition | 60Ni-23Cr-1Al-0.7Ti | ||

| Product shape |  Coil Coil |  Sheet Sheet |  Plate Plate |

| Workability | Hot working is relatively easy with NAS601.For hot working, maintain the temperature between 1050°C and 1200°C, though light work can be done at temperatures as low as 850°C. Avoid the temperature range between 650°C and 850°C to prevent cracking. After hot working, we also recommend cooling through the temperature range of 500 to 800°C as fast as possible to avoid carbide precipitation. NAS601 has superior cold workability, similar to Type 310S and Alloy 800. | ||

| Weldability | Similar to standard austenitic stainless steels, weld NAS601 using techniques such as TIG, MIG, and shield metal arc welding. For edge preparation, mechanical cutting is desirable. Wide U and V groove angles should be used. Care should be taken to ensure its welding portion is clean as NAS601 is sensitive to surface contamination. AWS ERNiCrFe-11, AWS ERNiCrCoMo-3, AWS ENiCrFe-2, or AWS ENiCrFe-3 are commonly used. | ||

| Heat Treatment | NAS601 is non-hardenable by thermal treatment. Typical heat treatments are as follows: Annealing: 950°C minimum, rapid cooling. Solution treatment: 1100°C-1200°C, rapid cooling. For applications requiring high strength at elevated temperatures, solution treatment is recommended. | ||

| Applications | Heat treatment fixtures, Muffle furnace, Radiant tube, Chemical plants, Automobile glow plug. | ||

Grade/Standard

| Nippon Yakin Grade | JIS | ASTM | EN |

|---|---|---|---|

| NAS601 | NCF601 | UNS N06601 | 2.4851 |

Chemical Composition

| C | Si | Mn | P | S | Ni | Cr | Cu | Al | Ti | B | Fe | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Specification (NCF601) | ≤0.10 | ≤0.50 | ≤1.00 | ≤0.030 | ≤0.015 | 58.00–63.00 | 21.00–25.00 | ≤1.00 | 1.00–1.70 | — | — | Bal. |

| Specification (UNS N06601) | ≤0.10 | ≤0.50 | ≤1.00 | — | ≤0.015 | 58.00–63.00 | 21.00–25.00 | ≤1.00 | 1.00–1.70 | — | — | Bal. |

| Specification (EN 2.4851) | 0.03–0.10 | — | ≤1.00 | ≤0.020 | ≤0.015 | 58.00–63.00 | 21.00–25.00 | ≤0.50 | 1.00–1.70 | — | — | ≤0.50, ≤0.006, ≤18.00 |

Physical Properties

| Density [g/cm³] | 8.07 |

| Specific heat [J/kg•K] | 451 |

| Electrical resistivity [μΩ•cm] | 119 |

| Thermal conductivity [W/m•K] | 11.1 |

| Average coefficient of thermal expansion [10⁻⁶/°C] | 30–100°C 13.6 |

| 30–300°C 14.2 | |

| 30–500°C 15.1 | |

| 30–700°C 15.9 | |

| 30–900°C 16.7 | |

| Young’s modulus [MPa] | 20.5 × 10⁴ |

| Curie point [°C] | −124 |

| Magnetism [μ] | None |

| Melting range [°C] | 1345–1384 |

Mechanical Properties

Mechanical Properties at Room Temperature

| 0.2% proof stress [MPa] | Tensile strength [MPa] | Elongation [%] | Hardness [HBW] [HRBW] | |

|---|---|---|---|---|

| Specification (NCF601 annealing) | ≥195 | ≥550 | ≥30 | — |

| Specification (NCF601 solution treatment) | ≥205 | ≥550 | ≥30 | — |

| Specification (UNS N06601) | ≥205 | ≥550 | ≥30 | — |

| Specification (EN 2.4851) | ≥205 | ≥550–750 | ≥30 | ≤220 |

| Example Hot-rolled plate 10 mm2 | 287 | 635 | 53 | 153 |

| Example Cold-rolled sheet 2 mm2 | 351 | 682 | 44 | 85 |

Heat Resistance

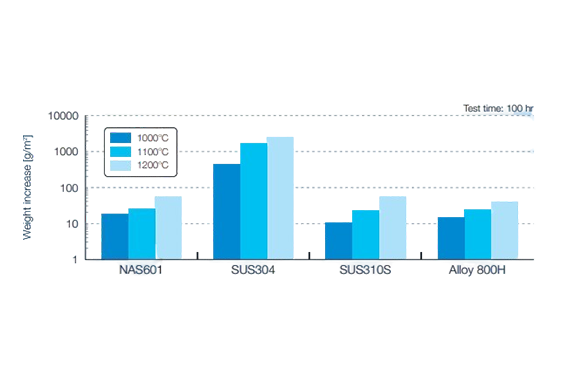

Continuous Oxidation Properties

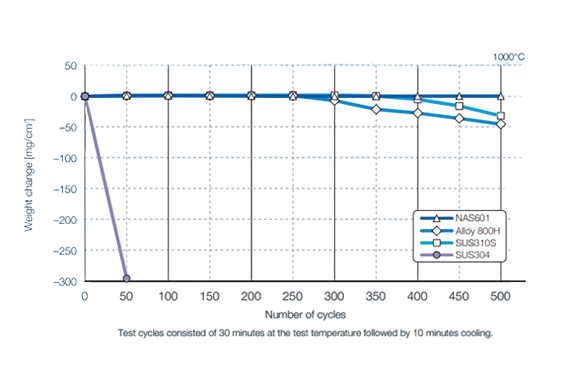

Cyclic Oxidation Properties

Cyclic oxidation properties for NAS601 are superior to Type 310S and Alloy 800H. This makes NAS601 optimal for use in environments subjected to repeated heating and cooling.

Workability

Hot working is relatively easy with NAS601. For hot working, temperatures should be between 1050 and 1200°C, although light work may be done at temperatures as low as 850°C. The temperature range between 650 and 850°C should be avoided as cracking may occur. After hot working, we also recommend cooling through the temperature range of 500 to 800°C as fast as possible to avoid carbide precipitation. NAS601 has superior cold workability, similar to Type 310S and Alloy 800.

Weldability

As with standard austenitic stainless steels, NAS601 may be welded using techniques such as TIG, MIG, and shield metal arc welding. For edge preparation, mechanical cutting is desirable. Wide U- and V-groove angles should be used. Care should be taken to ensure its welding portion is clean as NAS601 is sensitive to surface contamination. AWS ERNiCrFe-11, AWS ERNiCrCoMo-1, AWS ENiCrFe-2, or AWS ENiCrCoMo-1 are commonly used.

Heat Treatment

NAS601 is non-hardenable by thermal treatment. Typical heat treatments are as follows:

- Annealing: 950°C minimum, rapid cooling.

- Solution treatment: 1100°C–1200°C, rapid cooling.

For applications requiring high strength at elevated temperatures, solution treatment is recommended.

Applications

- Heat treatment fixtures

- Muffe furnace

- Radiant tube

- Chemical plants

- Automobile glow plug

Related Products

-

Nippon Yakin Kogyo NASNM17 Non-Magnetic Alloys

-

Nippon Yakin Kogyo NAS335X Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NASH330 Heat Resistant Alloys

-

Nippon Yakin Kogyo NASNi201 Corrosion Resistant Pure Nickel

-

Nippon Yakin Kogyo NAS254N Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS800 Heat Resistant Alloys