Nippon Yakin Kogyo Co., Ltd

Nippon Yakin Kogyo NASH38X Heat Resistant Alloys

Manufacturer: Nippon Yakin Kogyo Co., Ltd

Model : NASH38X

NASH38X (UNS N08120)

Heat-Resistant Nickel Alloy

NASH38X (UNS N08120) is a high-nickel heat resistant alloy offering outstanding high-temperature strength and oxidation resistance. With a coarse grain structure controlled by high-temperature heat treatment and C, N, Nb components, NASH38X offers particularly high creep strength.

Nippon Yakin supplies NASH38X in plate form.

| Chemical Composition | 38Ni-25Cr-0.6Nb-0.2N |

| Product shape |  Plate |

| Workability | Cold workability is equivalent to standard austenitic stainless steel. |

| Weldability | NAS-HX is weldable by TIG, MIG, and shielded arc welding processes. AWS A5.9 ER3856 welding electrodes are commonly used. |

| Heat Treatment | NAS-HX exhibits an austenite structure similar to austenitic stainless steel and is heat treated in the same way. Typical heat treatment is as follows: Solution treatment: 1177-1232°C; Rapid cooling. |

| Pickling | A mixture of nitric and fluoric acid is used in pickling. |

Grade/Standard

| Nippon Yakin Grade | JIS | ASTM | UNS |

|---|---|---|---|

| NASH38X | — | ASTM B409 | UNS N08120 |

Chemical Composition

| C | Si | Mn | P | S | Ni | Cr | Co | Cu | |

|---|---|---|---|---|---|---|---|---|---|

| Specification ASTM B409 (UNS N08120) | ≤0.02 | — | ≤0.50 | ≤0.030 | ≤0.015 | 58.00–63.00 | 27.00–30.00 | — | ≤0.50 |

| Specification ASTM B409 (UNS N08120) | — | — | — | — | — | — | — | — | Bal. |

Physical Properties

Mechanical Properties

1. Mechanical Properties at Room Temperature

| Density [g/cm³] | 8 |

| Specific heat [J/kg•K] | 472 |

| Electrical resistivity [μΩ•cm] | 119 |

| Thermal conductivity [W/m•K] | 11.5 |

| Average coefficient of thermal expansion [10⁻⁶/°C] | 25–200°C 14.6 |

| 25–300°C 15.0 | |

| 25–600°C 16.2 | |

| 25–700°C 16.6 | |

| 25–900°C 17.0 | |

| Young’s modulus [MPa] | 19.6 × 10⁴ |

Mechanical Properties

1. Mechanical Properties at Room Temperature.

| 0.2% proof stress [MPa] | Tensile strength [MPa] | Elongation [%] | Hardness [HBW] | ||

| Specification ASTM B409 (UNS N08120) | ≥276 | ≥621 | ≥30 | — | |

| Example | Hot-rolled plate 16 mm2 | 318 | 726 | 51 | 176 |

2. Creep Properties

| Test condition | Rupture time [hr] | Elongation [%] | ||

| Example | Hot-rolled plate 16 mm2 | 816°C, 110MPa | 86 | 65 |

Heat Treatment and Grain Size

| Heat Treatment | Crystal Grain Size | |

| ASTM B409 (UNS N08120) | ≥1177°C | No. 5 or coarser |

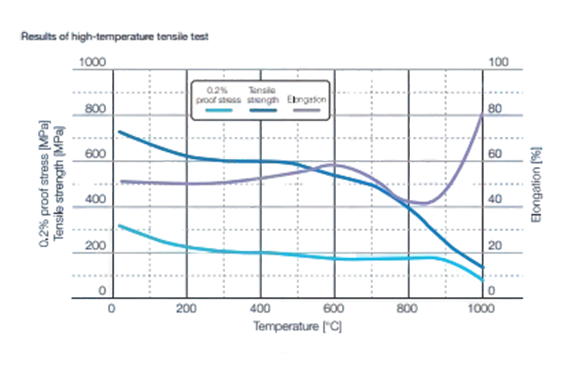

High Temperature Strength

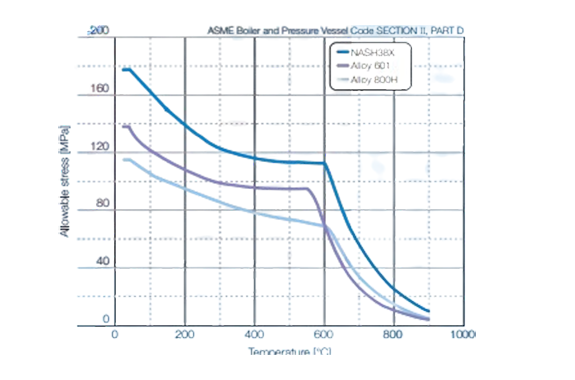

Allowable Stress

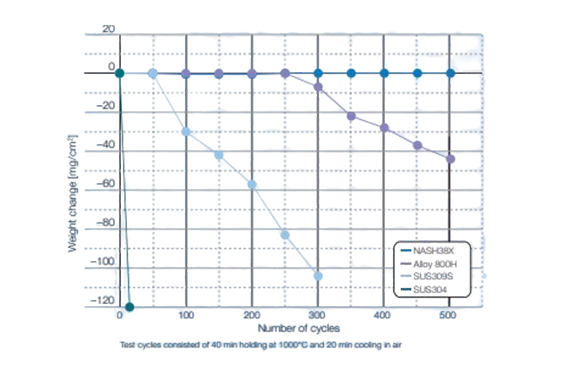

Cyclic Oxidation Properties

Workability

Cold workability is equivalent to standard austenitic stainless steel.

Weldability

NASH38X is weldable by TIG, MIG, and shielded arc welding processes. AWS A5.9 ER3556 welding electrodes are commonly used.

Heat Treatment

NASH38X exhibits an austenite structure similar to austenitic stainless steel and is heat-treated in the same way. Typical heat treatment is as follows:

- Solution treatment: 1,177–1,232°C; Rapid cooling.

Pickling

A mixture of nitric and hydrofluoric acid is used in pickling.

Properties

NASH38X provides outstanding high-temperature strength, oxidation resistance, and carburization resistance, as well as excellent creep characteristics in temperatures of 800°C and above.

Applications

- Furnace parts

- Heat treatment fixtures

Related Products

-

Nippon Yakin Kogyo NAS800 Heat Resistant Alloys

-

Nippon Yakin Kogyo NAS355N Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NASNi201 Corrosion Resistant Pure Nickel

-

Nippon Yakin Kogyo NAS600 Heat Resistant Alloys

-

Nippon Yakin Kogyo NAS42 Controlled Expansion Alloys

-

Nippon Yakin Kogyo NAS254N Corrosion Resistant Alloys