Nippon Yakin Kogyo Co., Ltd

Nippon Yakin Kogyo NASH880 Corrosion Resistant Alloys

Manufacturer: Nippon Yakin Kogyo Co., Ltd

Model: NASH880

NASH880

Heat Resistant Stainless Steel

NASH880 is an austenitic stainless steel which was developed by Nippon Yakin. It is suitable for use in high-grade sheathed heater tubes and provides excellent corrosion resistance in wet environments such as hot water supply devices. Nippon Yakin supplies NASH880 in sheet and strip forms.

| Chemical Composition | 25Ni-23.5Cr-1.2Mo-0.3Al-0.3Ti | |

| Product Shape |  Coil Coil |  Sheet Sheet |

| Weldability | NAS H880 welded tube has good formability. There is no crack on the bead after several forming tests. | |

| Blackening Property | Emissivity of NAS H880 after blackening heat treatment is the same level as alloy 800 (Low C%). | |

| Heat Treatment | Heat treatment of NASH880 can be performed in the same manner as with other austenitic stainless steels. The heat treatment temperature range which is normally used is as follows: Solution treatment: 1000~1100℃; water cooling | |

| Applications | Sheathed heater, Furnace parts | |

Steel Grade/Standard

| Nippon Yakin Grade | JIS | ASTM | EN |

|---|---|---|---|

| NASH880 | — | — | — |

Chemical Composition

| Specification | C | Si | Mn | P | S | Ni | Cr | Mo | Cu | Al | Ti | Co | N |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NASH880 | ≤0.030 | 0.30 – 0.50 | 0.35 – 0.65 | ≤0.025 | ≤0.002 | 24.50 – 27.00 | 22.80 – 23.90 | 1.15 – 1.35 | ≤0.25 | 0.20 – 0.40 | 0.25 – 0.45 | 0.05 – 1.00 | ≤0.02 |

Physical Properties

| Density [g/cm³] | 7.92 |

|---|---|

| Specific heat [J/kg·K] | 462 |

| Electrical resistivity [µΩ·cm] | 92.5 |

| Thermal conductivity [W/m·K] | 12.3 |

| Average coefficient of thermal expansion [10⁻⁶/°C] | 25 – 200°C: 15.6 25 – 400°C: 16.4 25 – 600°C: 16.8 25 – 800°C: 17.6 25 – 1,000°C: 18.4 |

| Young’s modulus [MPa] | 19.4 × 10⁴ |

| Magnetism | None |

| Melting range [°C] | 1,380 – 1,407 |

Mechanical Properties

Mechanical Properties at Room Temperature

| Specification | 0.2% proof stress [MPa] | Tensile strength [MPa] | Elongation [%] |

|---|---|---|---|

| Specification (NASH880) | ≥205 | ≥520 | ≥30 |

| Example: Cold-rolled sheet 0.5mm | 280 | 587 | 42 |

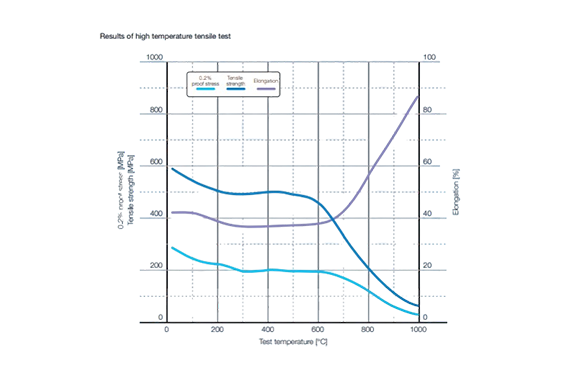

High Temperature Strength

Corrosion Resistance

Corrosion Resistance

1. Crevice Corrosion Resistance

Test condition

① Multicrevice test piece

② Test temperature: 80°C

③ Test time: 24 hr

| NaCl | 5% | 10% | ||

|---|---|---|---|---|

| alloy825 | NASH880 | alloy825 | NASH880 | |

| alloy825 | ○ | ○ | ○ | × |

| alloy 800 (Low C%) | ○ | × | ○ | × |

○: No corrosion ×: Corrosion

2. Stress Corrosion Cracking Resistance

Test condition

① U-bend test piece

② Liquid solution: 10% NaCl

③ Test time: 74 hr

| Temperature | 180°C | 200°C | 220°C | |||

|---|---|---|---|---|---|---|

| alloy825 | NASH880 | alloy825 | NASH880 | alloy825 | NASH880 | |

| alloy825 | ○ | ○ | ○ | ○ | × | × |

| alloy 800 (Low C%) | ○ | ○ | ○ | — | — | — |

○: No SCC ×: SCC

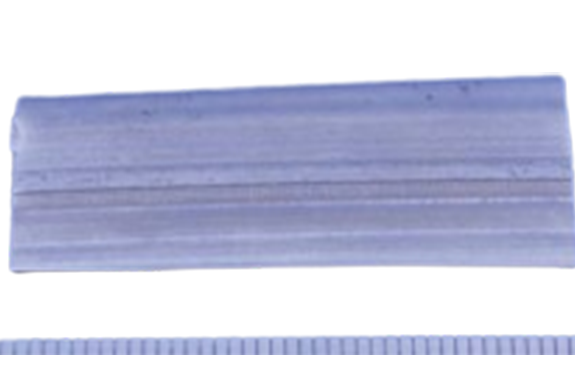

Weldability

NASH880 welded tube has good formability.

There is no crack on the head after several forming tests.

|  |  |

Flaring test | Flattening test | 180° Bending test (R=14mm) |

Formability of NASH880 welded tubes (8mmφ × 0.5mmt)

Blackening Property

Emissivity of NASH880 after blackening heat treatment is the same level as alloy 800 (Low C%).

|  |

NASH880 | Alloy 800 (Low C%) |

Appearance after blackening test

Heat Treatment

Heat treatment of NASH880 can be performed in the same manner as with other austenitic stainless steels. The heat treatment temperature range which is normally used is as follows:

Solution treatment: 1,000–1,100°C; water cooling

Related Products

-

Nippon Yakin Kogyo NASNW400 Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS255NM Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NASXM-19 High Strength Stainless Steels

-

Nippon Yakin Kogyo NASPB SoftMagnetic Alloys

-

Nippon Yakin Kogyo NASH880 Heat Resistant Alloys

-

Nippon Yakin Kogyo NASNM17 Non-Magnetic Alloys