Nippon Yakin Kogyo Co., Ltd

Nippon Yakin Kogyo NASHX Heat Resistant Alloys

Manufacturer: Nippon Yakin Kogyo Co., Ltd

Model : NASHX

NASHX (UNS N06002)

Heat-Resistant Nickel Alloy

NASHX (UNS N06002) is a nickel-chromium-iron-molybdenum alloy with outstanding strength and oxidation resistance in temperatures reaching as high as 1200°C. With superior workability and weldability as well, it is excellent for use in gas turbine members as well as various heating furnace parts. Nippon Yakin supplies this product in plate, sheet, and strip forms

| Chemical Composition | 47Ni-22Cr-9Mo-18Fe-1.5Co-0.6W | ||

| Product shape |  Coil Coil |  Sheet Sheet |  Plate Plate |

| Workability | We recommend using a range of 982 to 1177°C for hot working NAS-HXK. You can easily cold work NAS-HXK, though it requires greater force compared to standard austenitic stainless steels. Apply solution treatment after working to achieve favorable creep properties. | ||

| Weldability | Such techniques as TIG, MIG, and shield metal arc welding can be used for NAS-HXK as with standard austenitic stainless steels. Cleanse the weld surface of oxidizing scales, oil, and dirt before welding. | ||

| Heat Treatment | The recommended solution heat treatment temperature is between 1149 and 1177°C, the range stipulated in SAE AMS 5536L. Rapidly cool after heat treatment to prevent the formation of precipitates. | ||

| Applications | Gas turbine parts, Furnace parts, Semiconductor manufacturing equipment. | ||

Grade/Standard

| Nippon Yakin Grade | JIS | ASTM | AMS |

|---|---|---|---|

| NASHX | NW6002 | UNS N06002 | 5536 |

Chemical Composition

| C | Si | Mn | P | S | Ni | Cr | Co | Al | Ti | Cu | W | Fe | B | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Specification (NW6002) | 0.05–0.15 | ≤1.00 | ≤1.00 | ≤0.040 | ≤0.030 | Bal. | 20.50–23.00 | 0.50–2.50 | — | — | — | 0.20–1.00 | 17.00–20.00 | ≤0.010 |

| Specification (UNS N06002) | 0.05–0.15 | ≤1.00 | ≤1.00 | ≤0.040 | ≤0.030 | Bal. | 20.50–23.00 | 0.50–2.50 | — | — | — | 0.20–1.00 | 17.00–20.00 | ≤0.010 |

| Specification (UNS N06002) | 0.05–0.15 | ≤1.00 | ≤1.00 | ≤0.040 | ≤0.030 | Bal. | 20.50–23.00 | 0.50–2.50 | — | — | — | 0.20–1.00 | 17.00–20.00 | ≤0.010 |

Physical Properties

| Density [g/cm³] | 8.2 |

| Specific heat [J/kg•K] | 434 |

| Electrical resistivity [μΩ•cm] | 113 |

| Thermal conductivity [W/m•K] | 10.5 |

| Average coefficient of thermal expansion [10⁻⁶/°C] | 25–200°C 13.9 |

| 25–400°C 14.5 | |

| 25–600°C 15.0 | |

| 25–800°C 15.9 | |

| 25–1000°C 16.7 | |

| Young’s modulus [MPa] | 19.5 × 10⁴ |

| Magnetism [μ] | None |

| Melting range [°C] | 1290–1365 |

Mechanical Properties

Mechanical Properties at Room Temperature

| 0.2% proof stress [MPa] | Tensile strength [MPa] | Elongation [%] | Hardness [HV] [HBW] | |

|---|---|---|---|---|

| Specification (NW6002) | ≥245 | ≥660 | ≥35 | — |

| Specification (UNS N06002) | ≥240 | ≥655 | ≥35 | — |

| Specification (SAE AMS 5536M) | ≥310 | ≥724 | ≥35 | — |

| Example Hot-rolled plate 6 mm2 | 388 | 772 | 40 | — |

| Example Cold-rolled sheet 1.2 mm2 | 369 | 777 | 45 | 183 |

Impact Value

| Aging Treatment | Test Temperature (°C) | Impact Value (J/cm²) | |

| Solution-treated NASHX | Not applied | -196 | 138 |

| Not applied | -78 | 162 | |

| Not applied | Room temp. | 184 | |

| NASHX solution treated, then aged | 816°C for 50hr | Room temp. | 53 |

| 816°C for 150hr | Room temp. | 45 | |

| 816°C for 500hr | Room temp. | 41 |

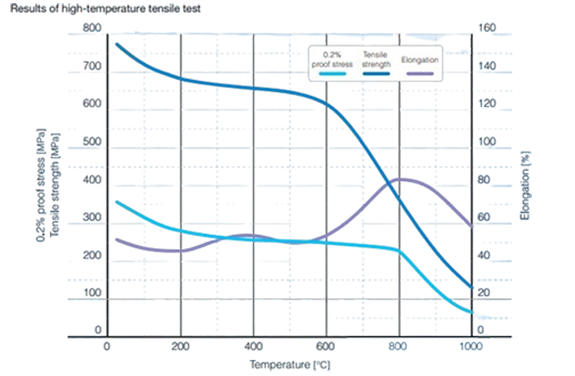

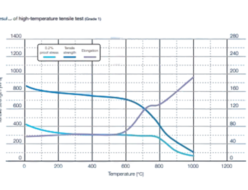

High Temperatures Strength

Creep Properties

| Test temperature [°C] | Load [MPa] | Rupture time [hr] | Rupture elongation [%] | ||

| Specification (SAE AMS 5536M) | 816 | 110 | ≥24 | ≥8 | |

| Example | Hot-rolled plate 35 mm2 | 816 | 110 | 63 | 76 |

| Hot-rolled plate 12 mm2 | 816 | 110 | 77 | 97 | |

| Cold-rolled sheet 3 mm2 | 816 | 110 | 93 | 97 | |

| Cold-rolled sheet 1.2 mm2 | 816 | 110 | 67 | 74 | |

Formability

A formability test on a 1.5mm thick sheet of solution-treated NASHX with a number 2B finish demonstrated that NASHX is easily formed through cold working.

| Erichsen Value (mm) | Limited Drawing Ratio | |

| NASHX | 10.3 | 2.10 |

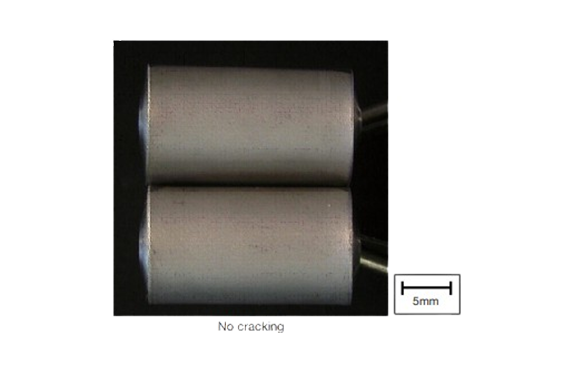

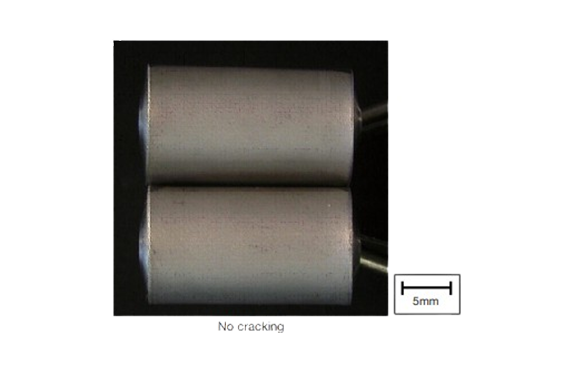

A 180° bending test was performed on a 3mm thick sheet of solution-treated NASHX with a number 2B finish to demonstrate the bending radius of 2t (where t is the nominal thickness).

Workability

We recommend using a range of 982 to 1177°C for hot working NASHX. NASHX can also be easily cold worked. Keep in mind that working NASHX requires greater force compared to standard austenitic stainless steels. Apply solution treatment after working to achieve favorable creep properties.

Weldability

Such techniques as TIG, MIG, and shield metal arc welding can be used for NASHX as with standard austenitic stainless steels. Before welding, the weld surface should be cleaned off oxidizing scales as well as oil and dirt.

Heat Treatment

The recommended solution heat treatment temperature is between 1149 and 1177°C, the range stipulated in SAE AMS 5536M. Rapid cooling is required after heat treatment to prevent precipitates.

Applications

- Gas turbine parts

- Furnace parts

- Semiconductor manufacturing equipment

Related Products

-

Nippon Yakin Kogyo NAS185N Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS800H, NAS800T Heat Resistant Alloys

-

Nippon Yakin Kogyo NAS36LG Controlled Expansion Alloys

-

Nippon Yakin Kogyo NASNW22 Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS625 Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS36 Controlled Expansion Alloys