Nippon Yakin Kogyo Co., Ltd

Nippon Yakin Kogyo NASNM15M Non-Magnetic Alloys

Manufacturer: Nippon Yakin Kogyo Co., Ltd

Model : NASNM15M

NASNM15M

Non-Magnetic High-Strength Stainless Steel

Nippon Yakin developed NASNM15M, a high-manganese austenitic stainless steel, with a composition of 17Cr-15Mn-4Ni.A high-manganese austenitic stainless steel, NASNM15M was developed by Nippon Yakin with a composition of 17Cr-15Mn-4Ni. Providing higher strength than conventional non-magnetic austenitic stainless steels, NASNM15M does not magnetize even if cold worked with force. Nippon Yakin supplies this product in plate, sheet, and strip forms.

| Chemical Composition | 17Cr-15Mn-4Ni-0.3N | ||

Product shape |  Coil Coil |  Sheet Sheet |

|

| Workability | The hot and cold workability of NASNM15M is basically the same as that of standard austenitic stainless steels such as Type 304, Type 316, etc. However, it is important to consider that this is a high-strength material in both cold and hot working processes. | ||

| Heat Treatment | The heat treatment is similar to austenitic stainless steels. The typical heat treatment is as follows: Solution heat treatment: 1050~1150°C; rapid cooling. | ||

Steel Grade/Standard

| Nippon Yakin Grade | JIS | ASTM |

|---|---|---|

| NASNM15M | — | — |

Chemical Composition

| Specification (NASNM15M) | C | Si | Mn | P | S | Ni | Cr | N |

|---|---|---|---|---|---|---|---|---|

| 0.040~0.090 | ≦0.90 | 14.00~15.00 | ≦0.045 | ≦0.015 | 4.00~4.60 | 16.50~17.50 | 0.30~0.35 |

Physical Properties

| Density | [g/cm³] | 8.00 |

|---|---|---|

| Specific heat | [J/kg·K] | 480 |

| Electrical resistivity | [µΩ·cm] | 77 |

| Thermal conductivity | [W/m·K] | 13.2 |

| Average coefficient of thermal expansion | [10⁻⁶/°C] | 30~100°C: 16.0 30~300°C: 17.7 30~500°C: 19.2 30~700°C: 20.3 |

| Young’s modulus | [MPa] | 19.6 × 10⁴ |

| Magnetism | None | |

| Melting range | [°C] | 1360~1412 |

Mechanical Properties

Mechanical Properties at Room Temperature

| Specification (NASNM15M) | 0.2% proof stress [MPa] | Tensile strength [MPa] | Elongation [%] | Hardness [HV] |

|---|---|---|---|---|

| Specification (NASNM15M) | ≧390 | ≧690 | ≧30 | ≦240 |

| Cold-rolled sheet | 461 | 789 | 45 | 211 |

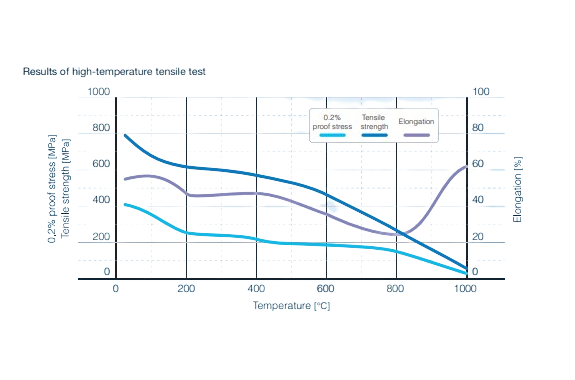

High Temperatures Strength

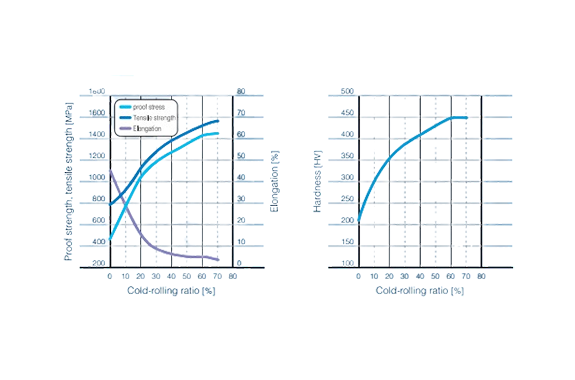

Work Hardening

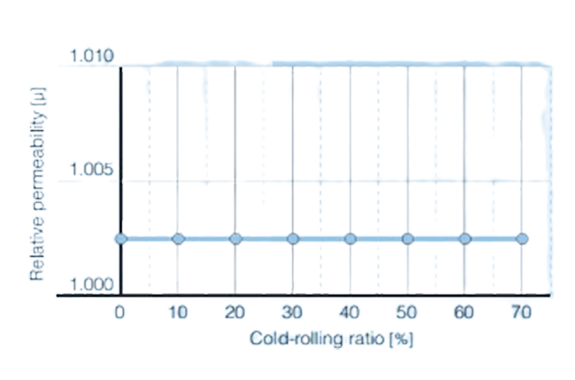

Permeability

Permeability

Even when cold working is applied, there is no variation in the relative permeability, and NASNM15M does not become magnetized.

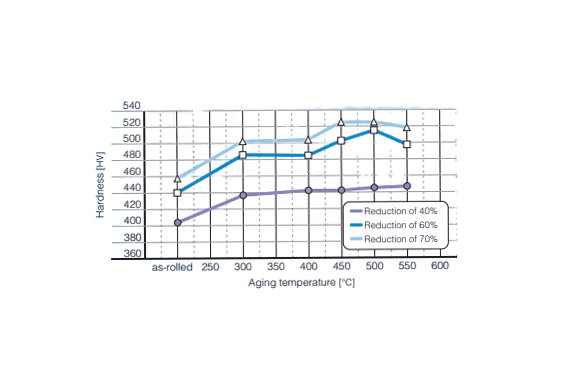

Age Hardening Behavior

After cold-rolling, the hardness of NASNM15M can be raised to between 50 and 70 Hv with heat treatment between 300 and 500°C.

Corrosion Resistance

Corrosion Resistance

Just as with the standard austenitic stainless steel Type 304, the corrosion resistance of NASNM15M shows no degradation even after strong cold working.

Evaluation of Pitting Corrosion Resistance

| Solution-treated NASNM15M | 0.34V |

|---|---|

| 60% cold-rolled NASNM15M | 0.31V |

Test condition: 5% NaCl, 30°C

Atmospheric Corrosion Resistance in Salt Spray Test

| Solution-treated NASNM15M | No rusting |

|---|---|

| 60% cold-rolled NASNM15M | No rusting |

Test condition: 5% NaCl, 35°C for 7 days

Workability

The hot and cold workability of NASNM15M is basically the same as that of standard austenitic stainless steels such as Type 304, Type 316, etc. However, the fact that this is a high strength material must be considered in both cold and hot working.

Heat Treatment

The heat treatment is similar to austenitic stainless steels. The typical heat treatment is as follows:

Solution heat treatment: 1030–1150°C; rapid cooling

Solution heat treatment: 1030–1150°C; rapid cooling

Applications

Non-magnetic springs, Electronic components, Components in which a non-magnetic property is required.

Related Products

-

Nippon Yakin Kogyo NAS36LG Controlled Expansion Alloys

-

Nippon Yakin Kogyo NAS254N Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS354N Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NASH330 Heat Resistant Alloys

-

Nippon Yakin Kogyo NASPB SoftMagnetic Alloys

-

Nippon Yakin Kogyo NAS64 Corrosion Resistant Alloys

Plate

Plate